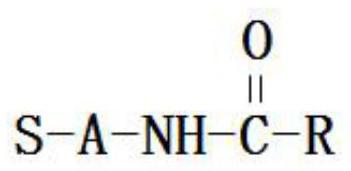

Reversible phase change atomized liquid gel containing glycosyl-aryl-amide-hydrocarbyl four-segment sugar-based gelling agent and its preparation method and application

A technology for atomizing liquid and gelling agent, applied in the field of atomized liquid gel and its preparation, can solve the problems of difficult to control the leakage of smoke liquid, increased research and development cost, complicated preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment is atomized liquid having a thermoreversible gel phase transition 1, comprising: a glycosylated gelling agent, 0.8wt%; atomization, 99.2wt%; based on the mass percentage of the atomized liquid, the said atomized liquid comprising: aerosolizing agent, which accounts for 92.0wt% of the atomized liquid; nicotine, which accounts for 2.0wt% of the atomized liquid; perfume, 6.0wt% which accounts for the atomized liquid; the atomizing agent is a mixture of glycerol and propylene glycol, glycerol and propylene glycol wherein the volume ratio of 5: 5.

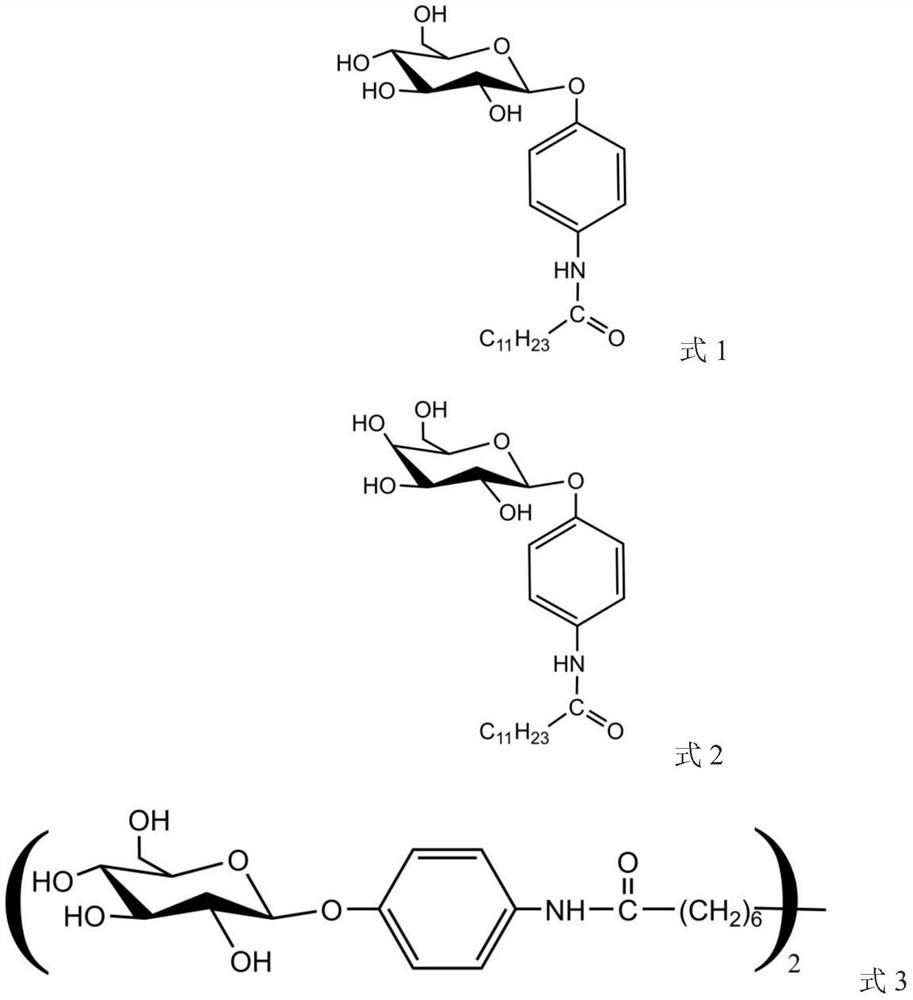

[0058] The chemical structural formula is glycosylated gelling agent:

[0059]

[0060] Glycosylation of the gelling agent Example 1 of the present embodiment has the following advantages: 1, the gelling agent in a sugar base, a hydrophobic hydrocarbon segment side, the other side is hydrophilic carbohydrate ligand, surfactant-like . Strong hydrogen bond glycosylated ligand causes a unidirectional molecular assembly...

Embodiment 2

[0064] This embodiment is a gel having a shear atomized liquid reversible phase transition characteristic 2, the chemical structure of formula glycosyl gelling agent which is used:

[0065]

[0066] Other preparation conditions, each group assigned the same ratio as in Example 1.

[0067] Directly to the molten atomized liquid according to the present embodiment is a gel solution was poured into the nebulizer reservoir cartridge, gelling After the solution was cooled to obtain an atomized liquid smoke bombs gel, which was used in the high frequency BAW oscillation means atomized, sol - gel phase transition critical shear stress of 580Pa, under high shear and shaken vigorously (acoustic frequency 2.4MHz), gel network structure is destroyed, gel viscosity decreases trapped atomized liquid is released, suction can be generated aerosol; aspiration after a few mouthfuls, stops vibrating, can quickly form a self-assembled gel, the viscosity increases again. The above process can be re...

Embodiment 3-4

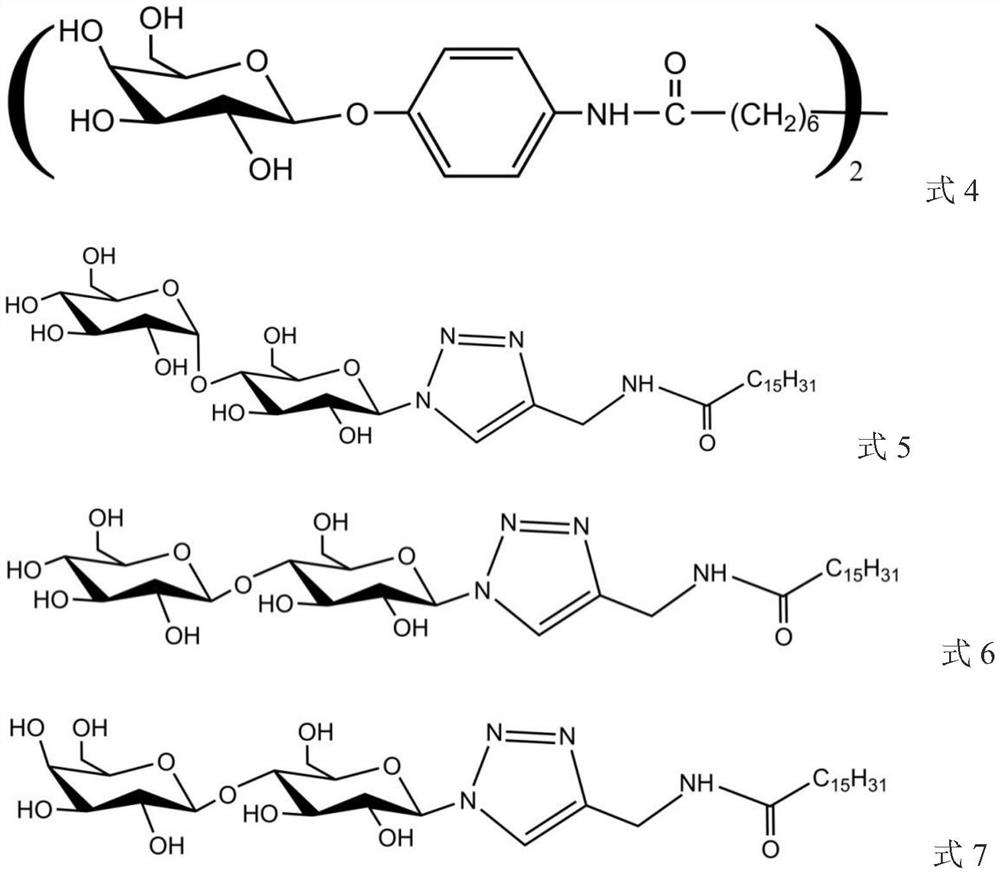

[0070] This embodiment is atomized and the atomized liquid 3 liquid gel 4 having a thermoreversible gel phase transition properties, using a chemical structural formula glycosyl gelling agent are:

[0071]

[0072] Other preparation conditions were the same as in Example 1.

[0073] Directly to the molten atomized liquid according to the present embodiment is made porous gel material 3 is injected and atomized liquid gel solution aerosol generating device 4, the solution was cooled until gelling is fixed to the porous material, the gel - sol phase transition temperature were 230 deg.] C and 235 deg.] C, after repeating several times the suction, atomized liquid gels 3 and 4 atomized liquid gel phase transition properties is still very clear, so the present embodiment preparation of atomized liquid condensate 3 and atomized liquid gel adhesive 4 applied to the electronic cigarette requires high temperature atomized liquid spray products.

[0074] Gel embodiment of the present emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com