Adjustable grid bar type round large-grain seed grading device

A grading device and grid bar technology, which is applied in the direction of grating, solid separation, and sieving, can solve the problems of poor flexibility, reduced sorting efficiency, and impact, and achieve the effects of low manufacturing cost, convenient operation, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

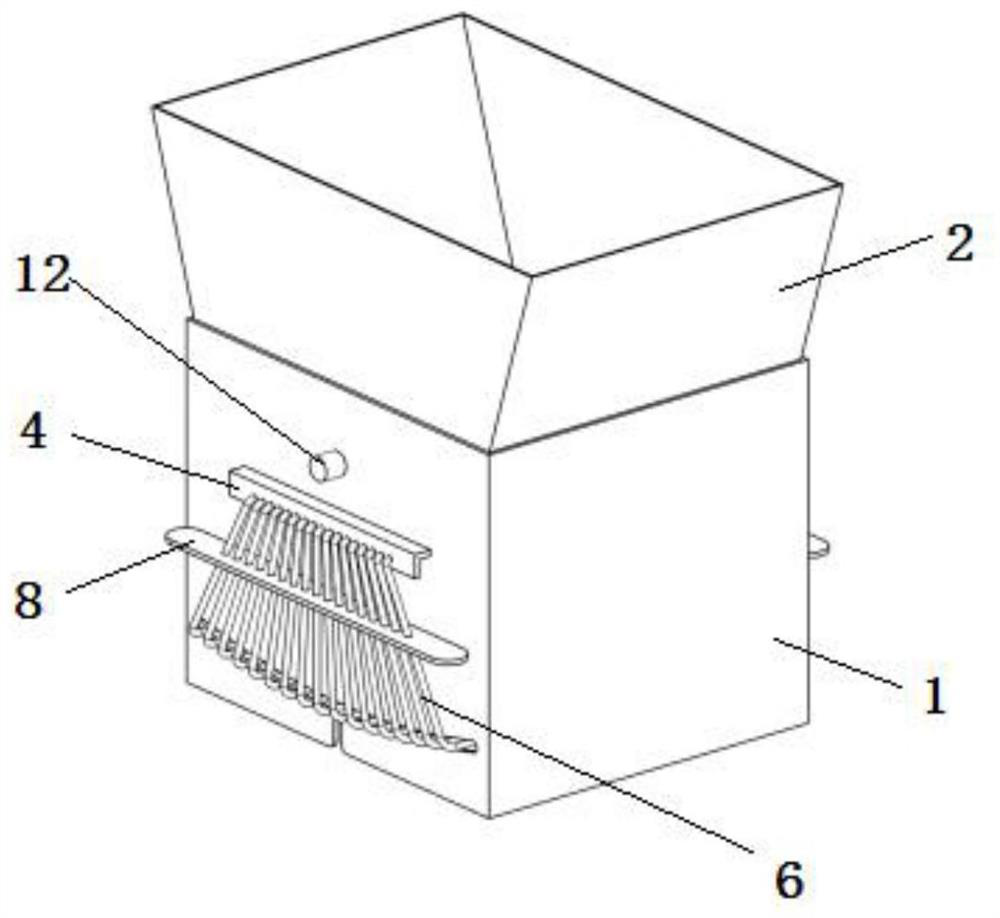

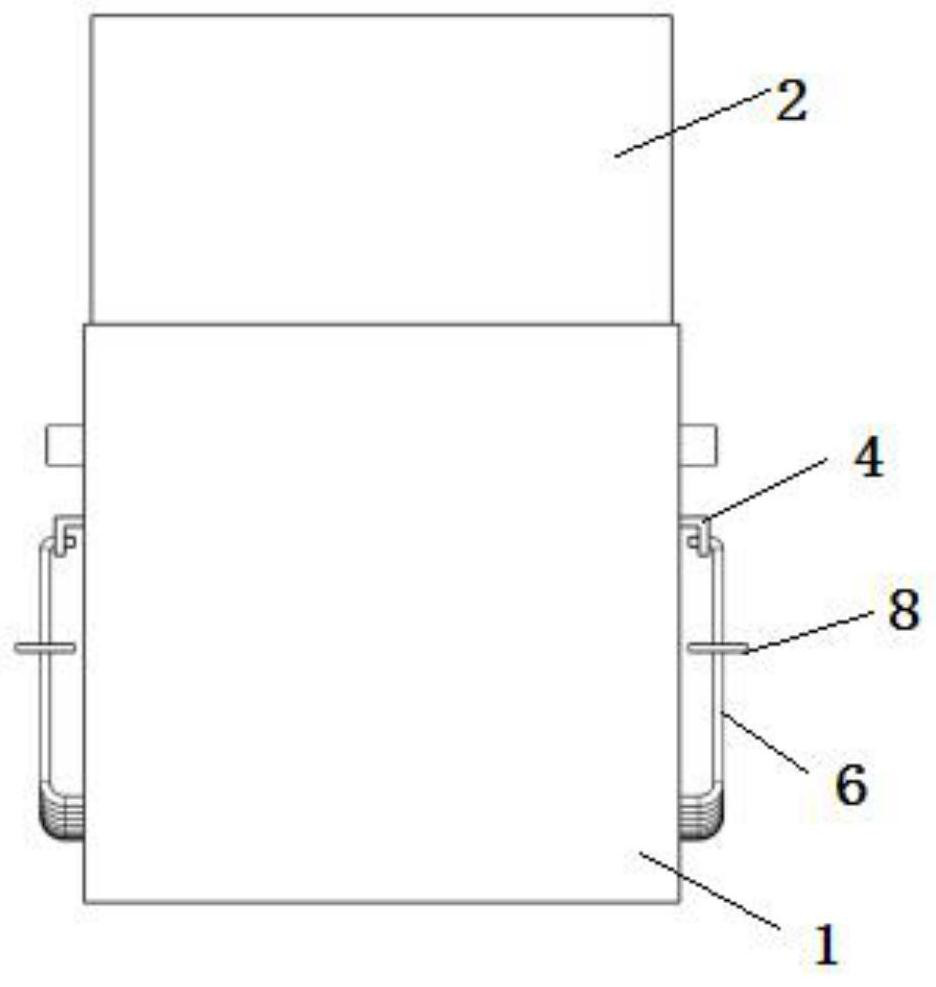

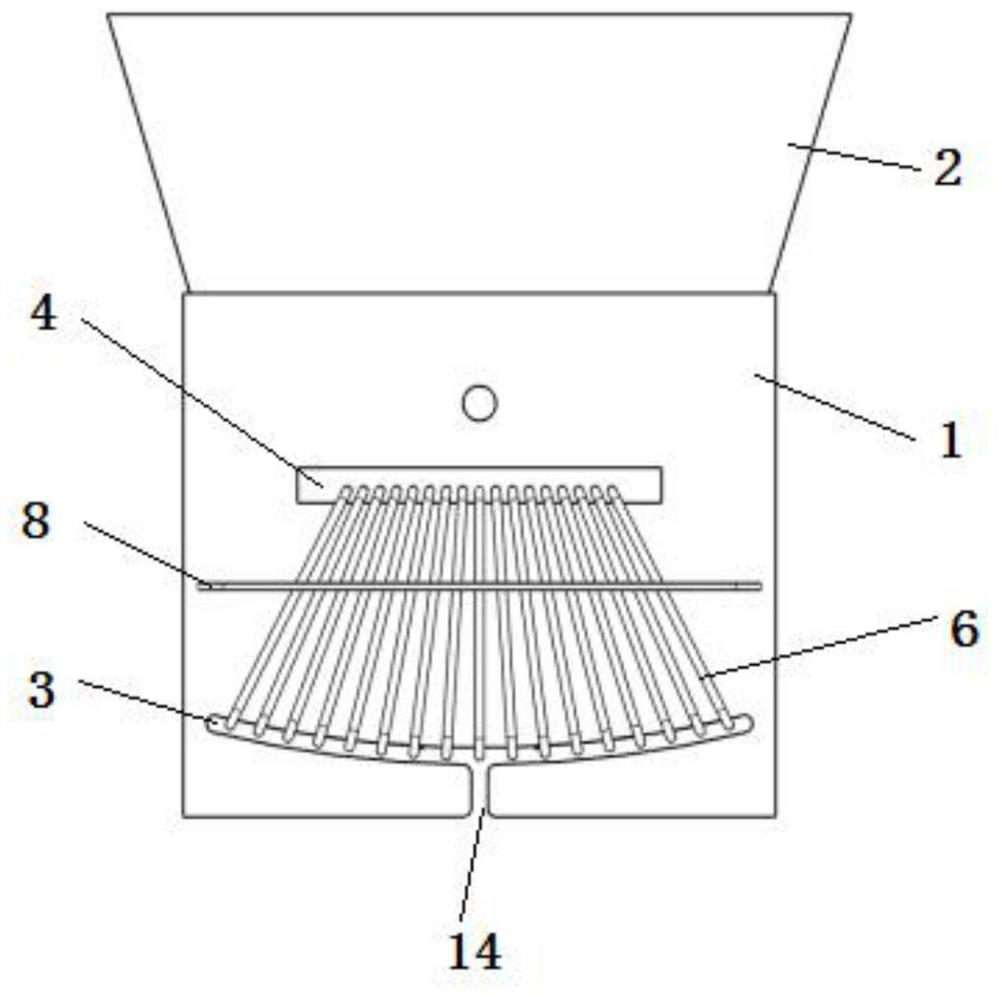

[0024] see Figure 1 to Figure 9 , this embodiment discloses a 6-type circular large-grain seed grading device with adjustable grids, including a box body 1 . The side walls on the left and right sides of the box body 1 are respectively provided with arc-shaped grooves 3, and the two arc-shaped grooves 3 are symmetrically arranged on the left and right sides. 4. There are multiple mounting holes 5 on the mounting strip 4, and the multiple mounting holes 5 are arranged in a row along the front and rear directions, and the multiple mounting holes 5 on the mounting strip 4 are evenly distributed along the front and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com