Power storage battery fault single body screening structure and method thereof

A power battery and battery technology, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of inability to measure single-cell voltage, time-consuming and labor-intensive, low work efficiency, etc., to improve the efficiency of anatomical analysis, the operation method is simple, The effect of increasing the height of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

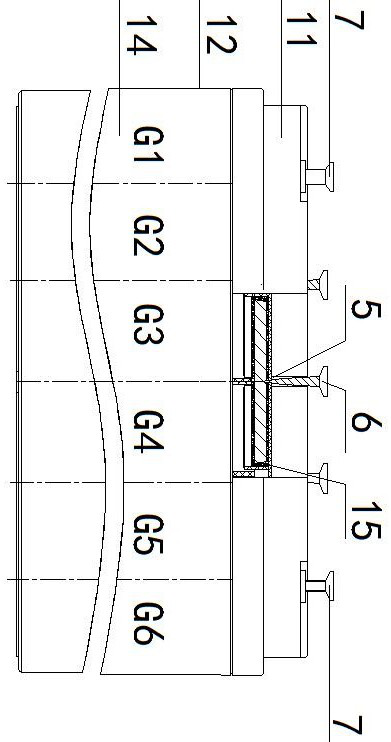

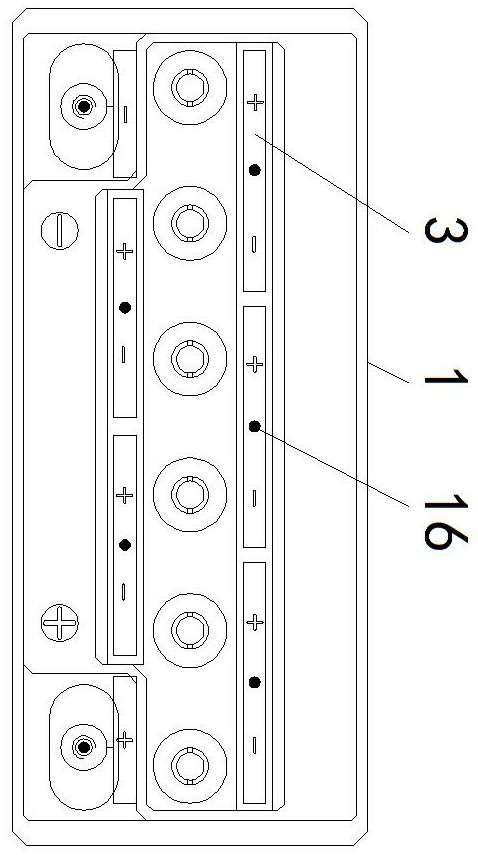

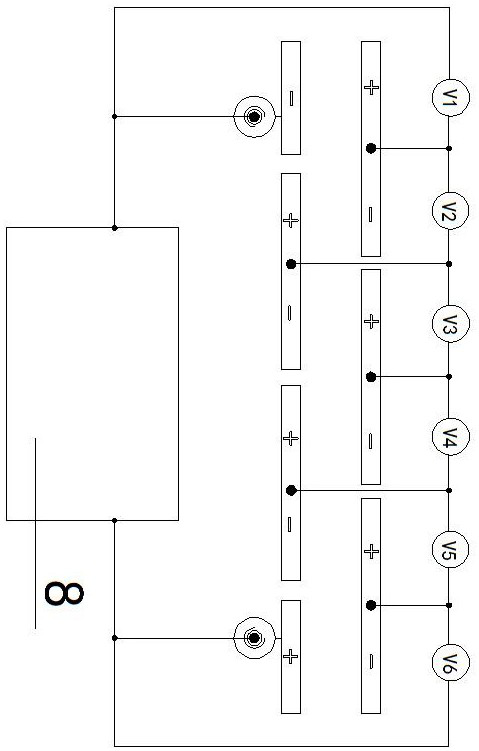

[0028] Embodiment 1: as Figure 1 to Figure 3 A power battery fault cell screening structure shown includes a battery 1, the battery 1 includes a middle cover 11, a bottom tank 12, and the inside of the bottom tank 12 is divided into a plurality of identical cells 14 by partitions, each cell There is a pole group inside each grid 14, and two adjacent pole groups are directly connected by a bus bar 3, and the bus bar 3 is sealed and fixed inside the middle cover 11 by glue, and the center of each bus bar 3 is directly above Blind holes 5 are drilled, and self-tapping screws 6 are threaded in each blind hole 5, and bolts 7 are threaded on the top of the positive and negative terminals of the battery 1, and the bolts 7 are respectively connected to the discharge instrument 8 through wires.

[0029] The blind hole 5 passes through the middle cover 11 and the glue layer 15 sequentially from top to bottom, and finally extends to the top surface of the bus bar 3; when the self-tappin...

Embodiment 2

[0041] 1. Choose a 12V, 20Ah defective battery;

[0042] 2. The discharge current is set to 40A, and the discharge time is set to 10min;

[0043] 3. Compared with the display of the discharge meter, record the voltage of each single cell:

[0044] V1 V2 V3 V4 V5 V6 1.77 1.96 1.97 1.89 1.93 1.95

[0045] From this, it can be judged that there is an abnormality in the first cell, and a mark is made on the battery cell. When dissecting and analyzing, just pull out the pole group in the first single cell and analyze.

Embodiment 3

[0047] 1. Choose a 12V, 32Ah defective battery;

[0048] 2. The discharge current is set to 62A, and the discharge time is set to 10 minutes;

[0049] 3. Compared with the display of the discharge meter, record the voltage of each single cell:

[0050] V1 V2 V3 V4 V5 V6 1.87 1.91 1.92 1.32 1.94 1.89

[0051]From this, it can be judged that there is an abnormality in the fourth cell, and a mark is made on the battery cell. When dissecting and analyzing, just pull out the pole group in the fourth cell and analyze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com