Laser welding machine capable of automatically rounding coiled tube motor stator

A laser welding machine, coil motor technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of not meeting the needs of large-scale production in factories and a large number of manual participation, saving manpower and improving work efficiency , to meet the effect of rotating needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

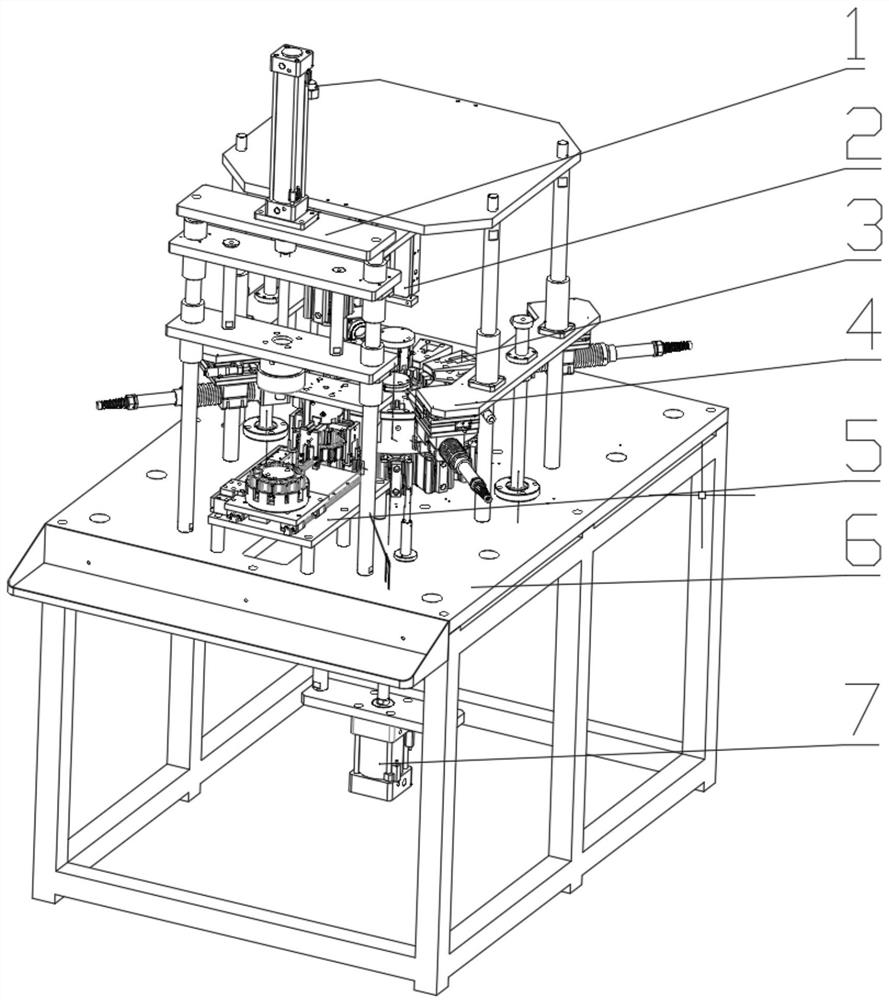

[0034] Such as figure 1 As shown, a laser welding machine for automatically forming a coil motor stator into a circle, including a pressing mechanism 1, a coil motor stator grasping mechanism 2, a clamping mechanism 3, a welding mechanism 4, a transmission mechanism 5, a frame 6 and a welding Fixture rotation mechanism 7.

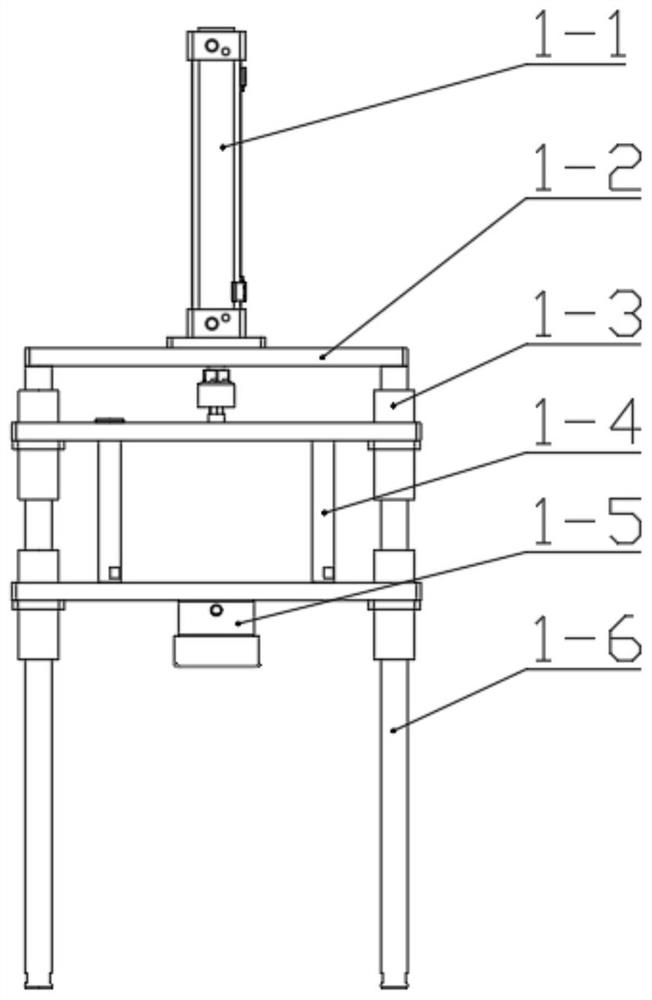

[0035] Such as figure 2 As shown, the pressing mechanism 1 includes a pressing cylinder 1-1, a pressing top plate 1-2, a pressing linear bearing 1-3, a pressing plate 1-4, a pressure head seat 1-5 and a pressing guide post 1-6 . The cylinder block of the pressing cylinder 1-1 is fixed on the pressing top plate 1-2; the upper ends of the two pressing guide posts 1-6 are fixed on the bottom surface of the pressing top plate 1-2, and the lower ends are all fixed on the frame 6; the lower pressing plate 1 The two ends of -4 and the two down-pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com