Bearing platform die and bearing platform outer frame body

A technology of outer frame and body, applied in construction, infrastructure engineering and other directions, can solve the problem of difficulty in assembling the platform, and achieve the effects of convenient splicing and alignment, convenient installation and high structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

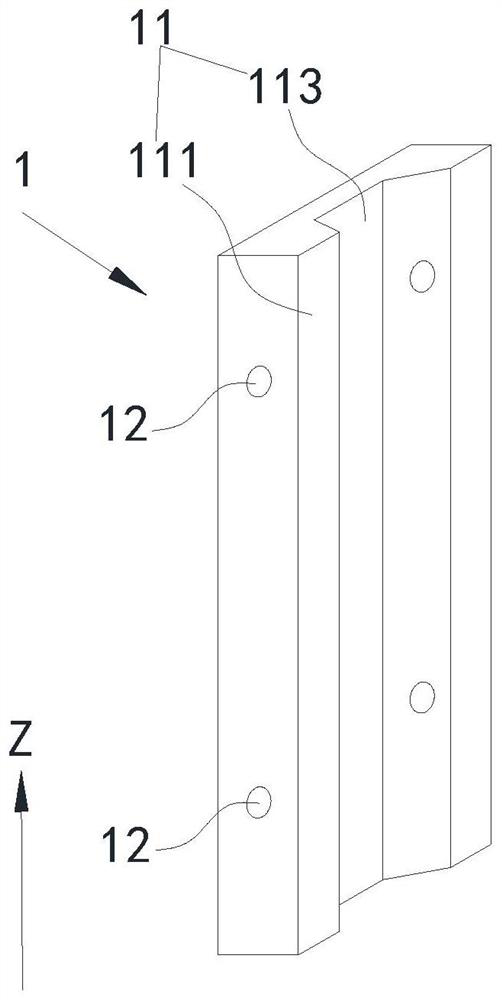

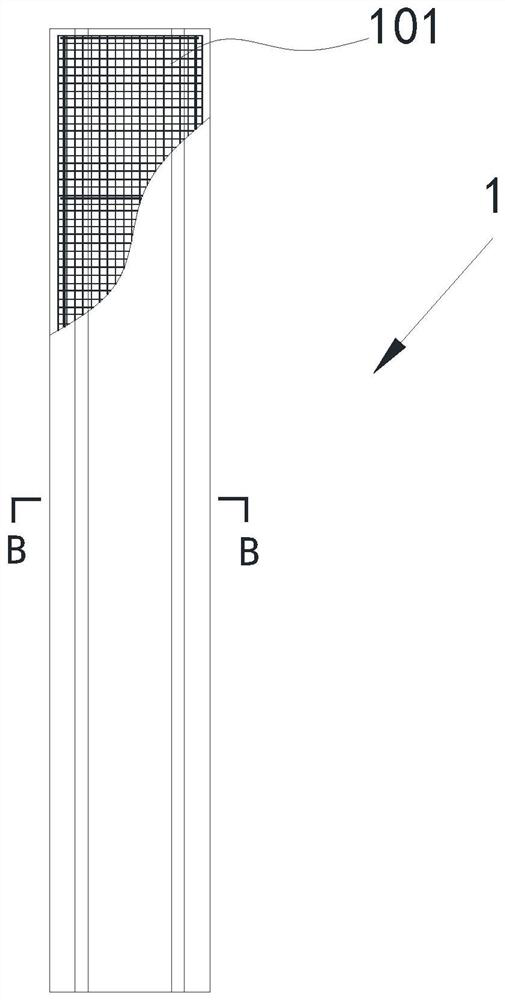

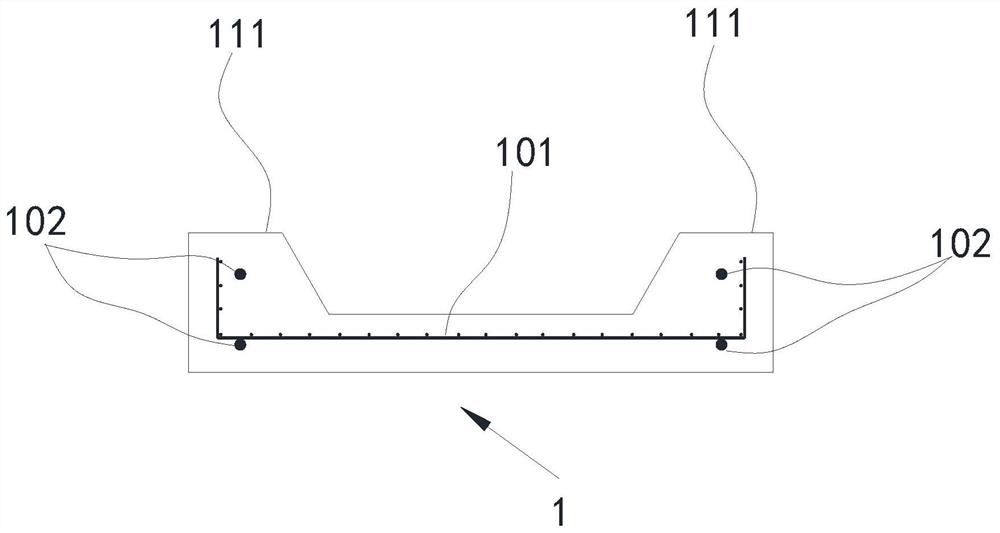

[0059] see Figure 1 to Figure 10 , this embodiment provides a platform formwork and a platform outer frame formed by splicing the platform formwork. Among them, the arrows X, Y, and Z are the coordinate system, Z is the vertical direction, that is, the height direction of the cap form, X is the horizontal direction, that is, the length direction of the cap form, and Y is the thickness direction of the cap form.

[0060] Such as figure 1 As shown, it is a schematic diagram of the three-dimensional structure of the platform mold 1 in the specific embodiment. The platform formwork 1 is a prefabricated concrete slab (ie concrete prefabricated part), and the shape of the platform formwork 1 is a cuboid. This cap formwork 1 is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com