Connecting structure suitable for modular steel structure

A connection structure and module connection technology, which is applied in the direction of building construction and construction, can solve the problems of unfavorable modular box column-to-column connection of square steel pipe columns, restrictions on the promotion and popularization of modular steel structure buildings, and insufficient joint stiffness. , to achieve the effect of clear force transmission path, reasonable force and reliable force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

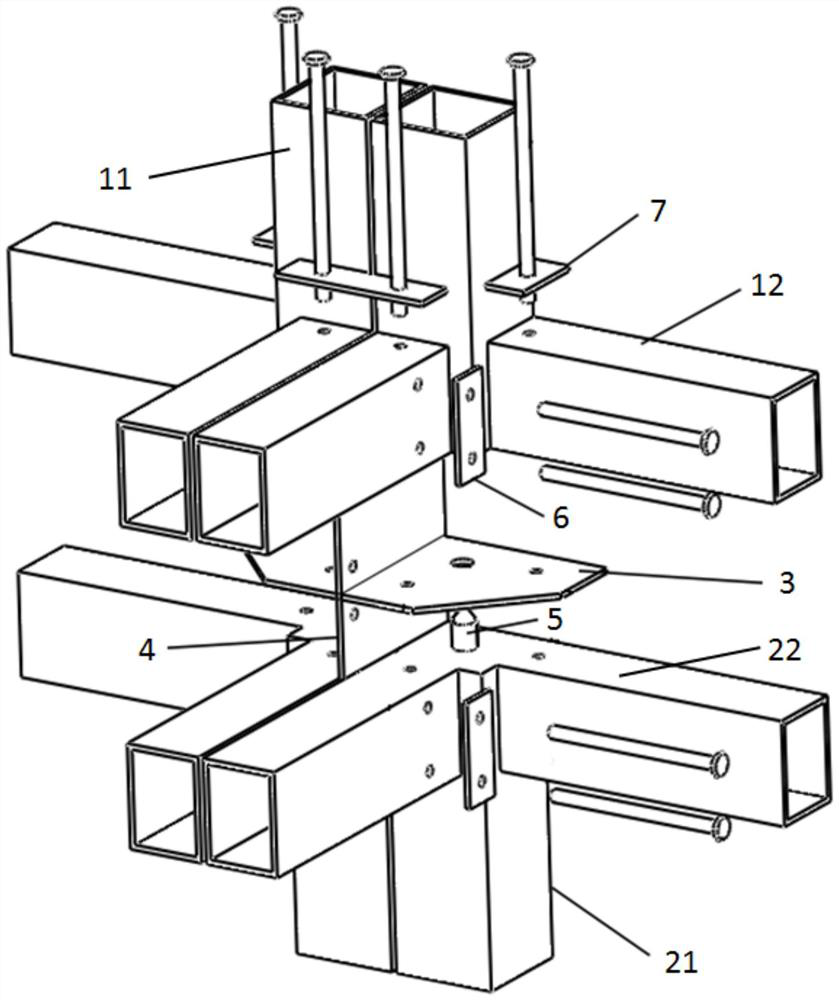

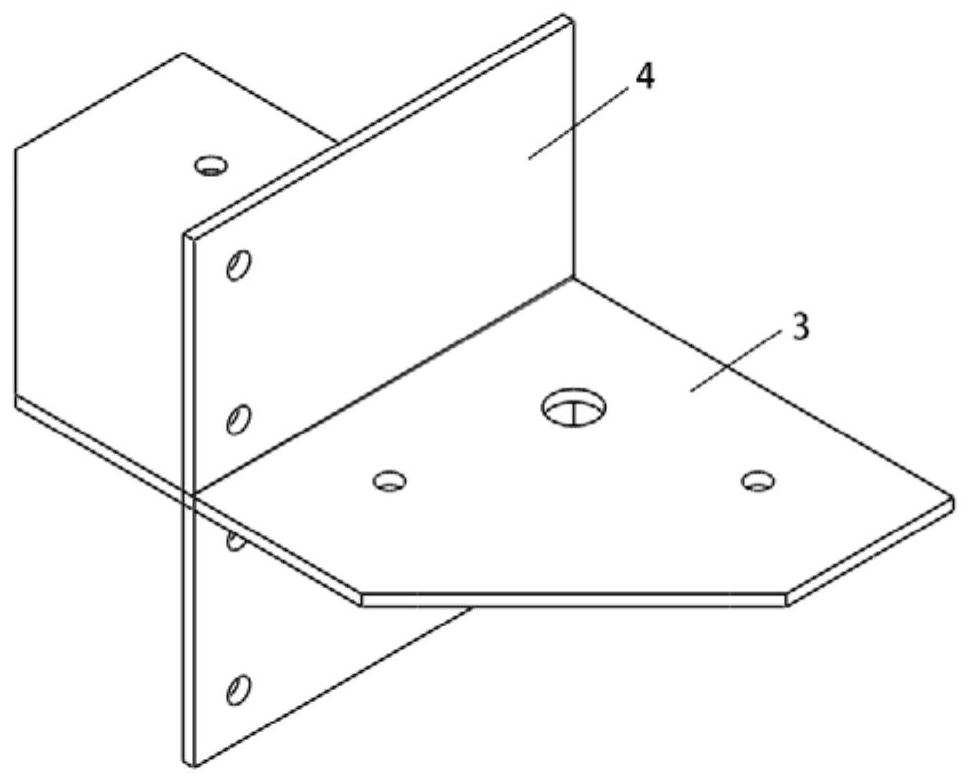

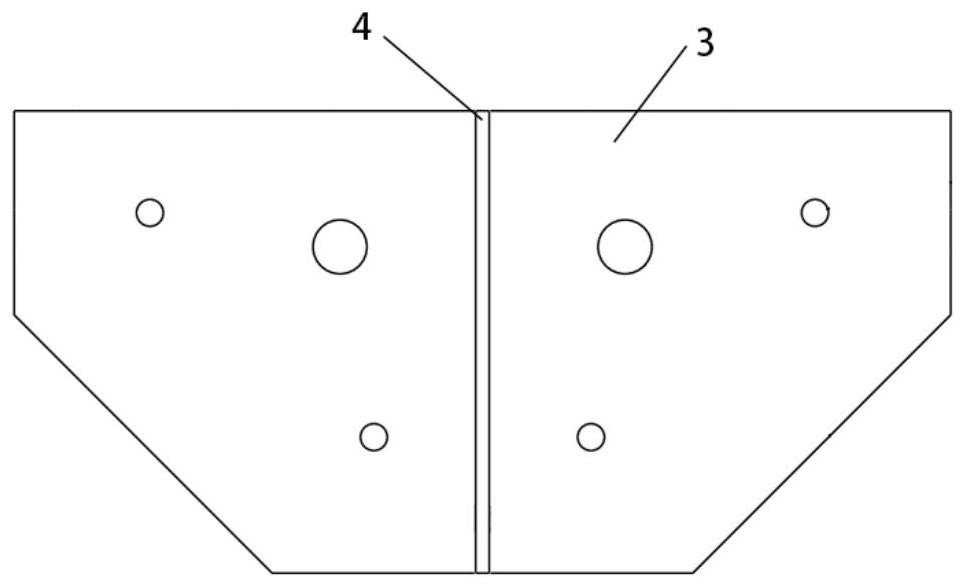

Embodiment 1

[0035] A connection structure suitable for modular steel structures such as figure 1 , 5 -8 and 11, the structure includes two upper modules and lower modules, arranged in mirror image, the upper module includes upper module column 11 and two upper module beams 12, the lower module includes lower module column 21 and two lower module beams 22; The two upper module beams 12 are in a V-shaped structure with an included angle of 90°. The structure of the lower module is almost the same as that of the upper module. Between the upper module and the lower module, there is a gusset plate that helps the upper module and the lower module of the module to be connected to each other. The upper module column 11, the gusset plate and the lower module column 21 are connected by bolts. The module beams 22 are locked by means of tension bolts. The upper module column 11 and the lower module column 21 adopt a square section, and the upper module beam 12 and the lower module beam 22 adopt a ...

Embodiment 2

[0043] Such as Figure 10 As shown, the difference from Embodiment 1 is that the number of the upper module and the lower module is one, and the connection method and construction method are similar to Embodiment 1.

Embodiment 3

[0045] Such as Figure 12 As shown, the difference from Embodiment 1 is that the number of upper modules and lower modules is 4, and the connection method and construction method are similar to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com