A device for automatically sticking floor tiles in building construction and its application method

A building construction and automatic technology, applied in construction, building structure and other directions, can solve the problems of difficult use of workers, high rework rate of single bricks, high labor intensity, etc., to avoid uneven fitting, avoid uneven laying, The effect of saving the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

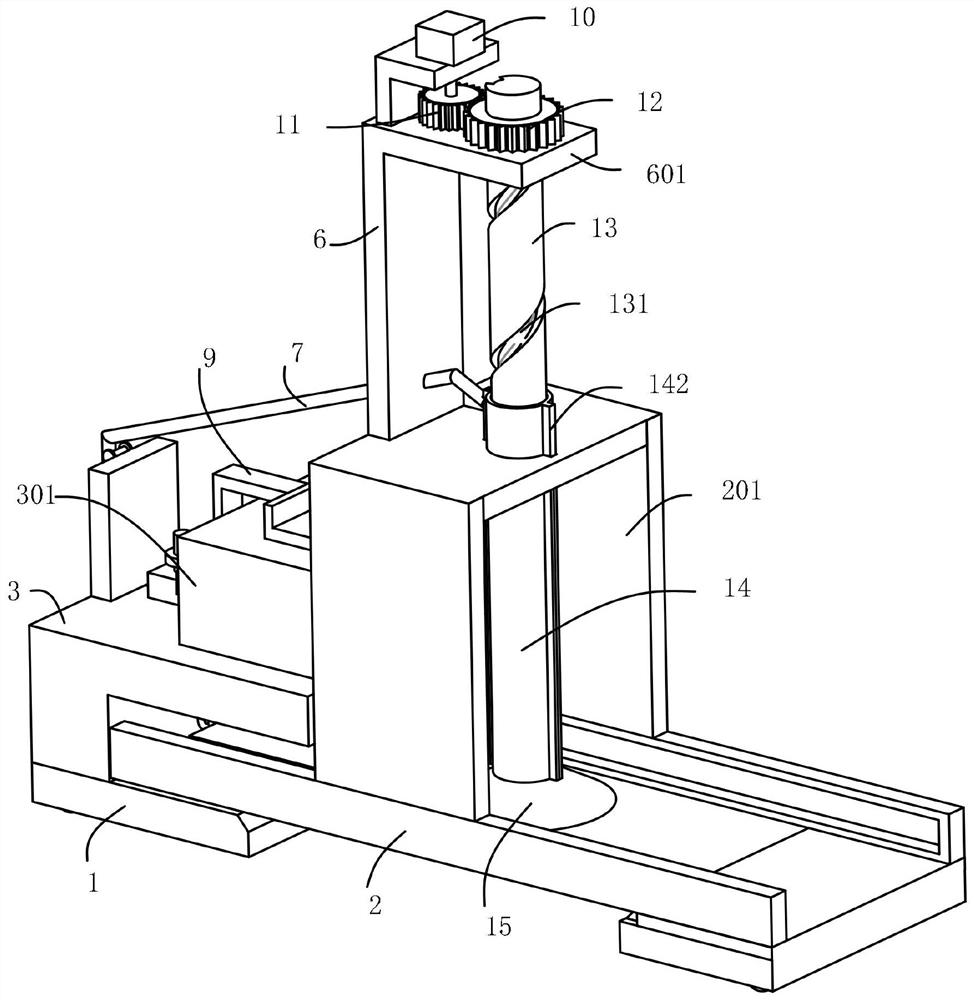

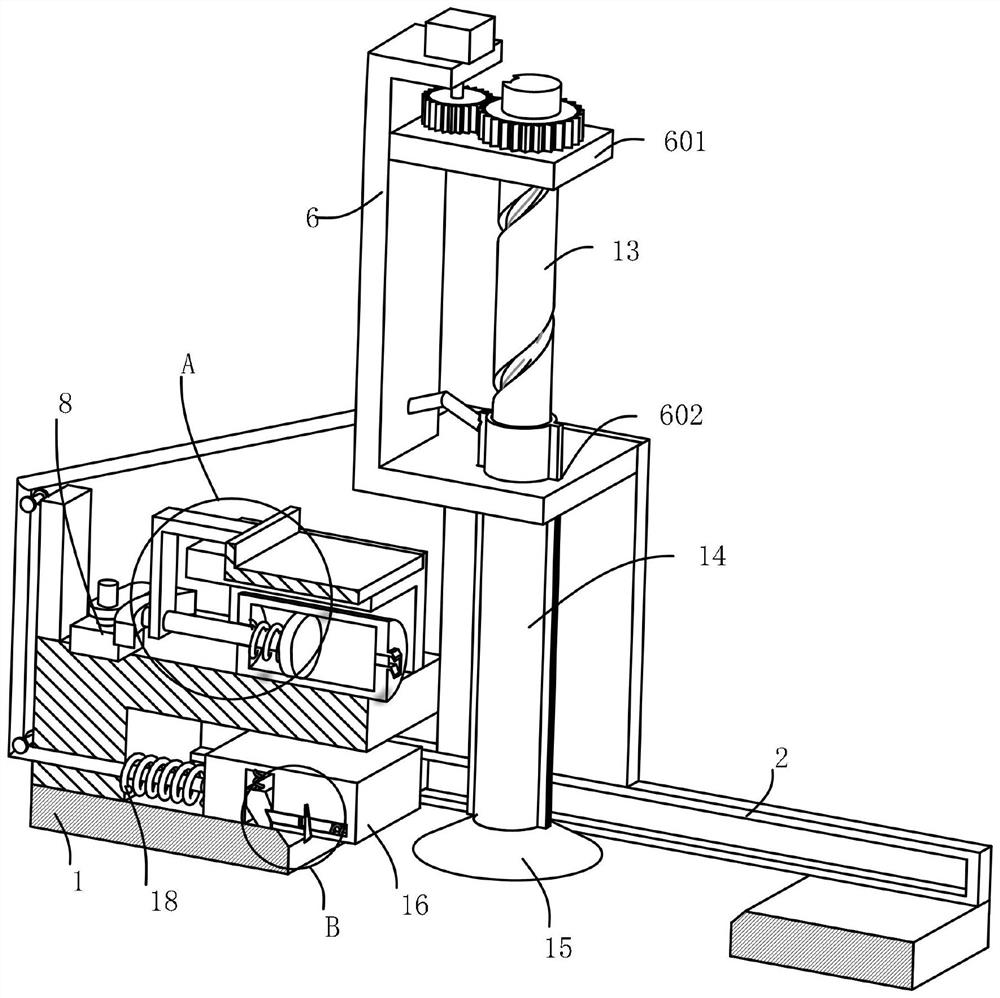

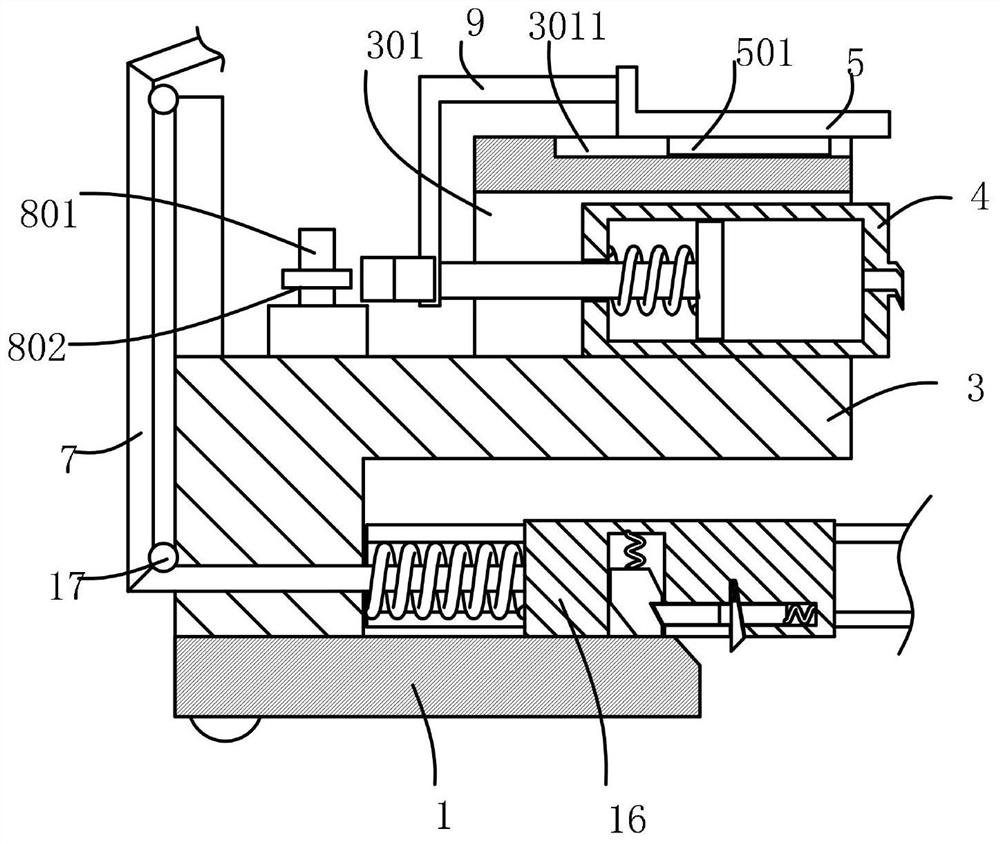

[0038] refer to figure 1 , figure 2 , image 3 , Image 6 and Figure 7 , an automatic floor tile installation for building construction, comprising two bases 1, the outer walls of the two bases 1 are connected with guide rails 2, the top of the base 1 is connected with a workbench 3, the outer wall of the workbench 3 is connected with a feeding mechanism, and the outer walls of the workbench 3 The top is connected with a fixed seat 301, the outer wall of the workbench 3 is connected with a mortar box 4, the outer wall of the fixed seat 301 is slidably connected with a placement plate 5, the feeding mechanism is connected with the mortar box 4 and the placement plate 5, and the outer walls of the two guide rails 2 are connected. plate 201, a support seat 6 is connected between the two fixed plates 201, the top of the support seat 6 is connected with a tile-laying mechanism, the outer wall of the guide rail 2 is slidingly connected with a scraper mechanism, and a pull-out m...

Embodiment 2

[0041] refer to Figure 1-4 , an automatic floor tile installation for building construction, which is basically the same as Embodiment 1, furthermore, the tile installation mechanism includes a second motor 10, the second motor 10 is fixedly connected to the top of the support base 6, and the output of the second motor 10 The end is connected with a second rotating shaft, the outer wall of the second rotating shaft is connected with the first gear 11, the outer wall of the first gear 11 is meshed with the second gear 12, the outer wall of the support seat 6 is connected with a support plate 601, the first gear 11 and the second gear 12 Both are rotatably connected to the outer wall of the support plate 601, the outer wall of the second gear 12 is connected with a rotating shaft 13, the outer wall of the rotating shaft 13 is sleeved with a moving tube 14, the moving tube 14 is slidably connected in the support seat 6, and the bottom of the moving tube 14 is connected with Vacu...

Embodiment 3

[0044] refer to Figure 1-7 , an automatic floor tile installation for building construction, which is basically the same as Embodiment 1, furthermore, the two ends of the stay rope 7 are respectively connected to the outer walls of the moving seat 16 and the moving pipe 14, and the outer walls of the workbench 3 and the supporting seat 6 are set There are auxiliary wheels 17, and the stay cord 7 is slidably connected to the outer wall of the auxiliary wheels 17; it is beneficial to guide the direction of movement of the stay cord 7.

[0045] The invention also discloses a method for using an automatic floor tile installation for building construction, which includes the following steps:

[0046] S1: The mortar box 4 is filled with mortar, the floor tiles are placed on the placement plate 5, and the first motor 8 is controlled to run so that the output end of the first motor 8 drives the first rotating shaft 801 to rotate, so that the first rotating shaft 801 drives the cam 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com