Horizontal two-degree-of-freedom electromagnetic vibration isolation device based on parallel connection of magnetic gravitational positive and negative stiffness

A technology of positive and negative stiffness and magnetic attraction, applied in magnetic springs, shock absorbers, non-rotational vibration suppression, etc., can solve the problem of less electromagnetic vibration isolation devices, improve utilization, reduce stiffness and initial vibration isolation frequency , The effect of realizing near-zero stiffness characteristics and near-zero frequency vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

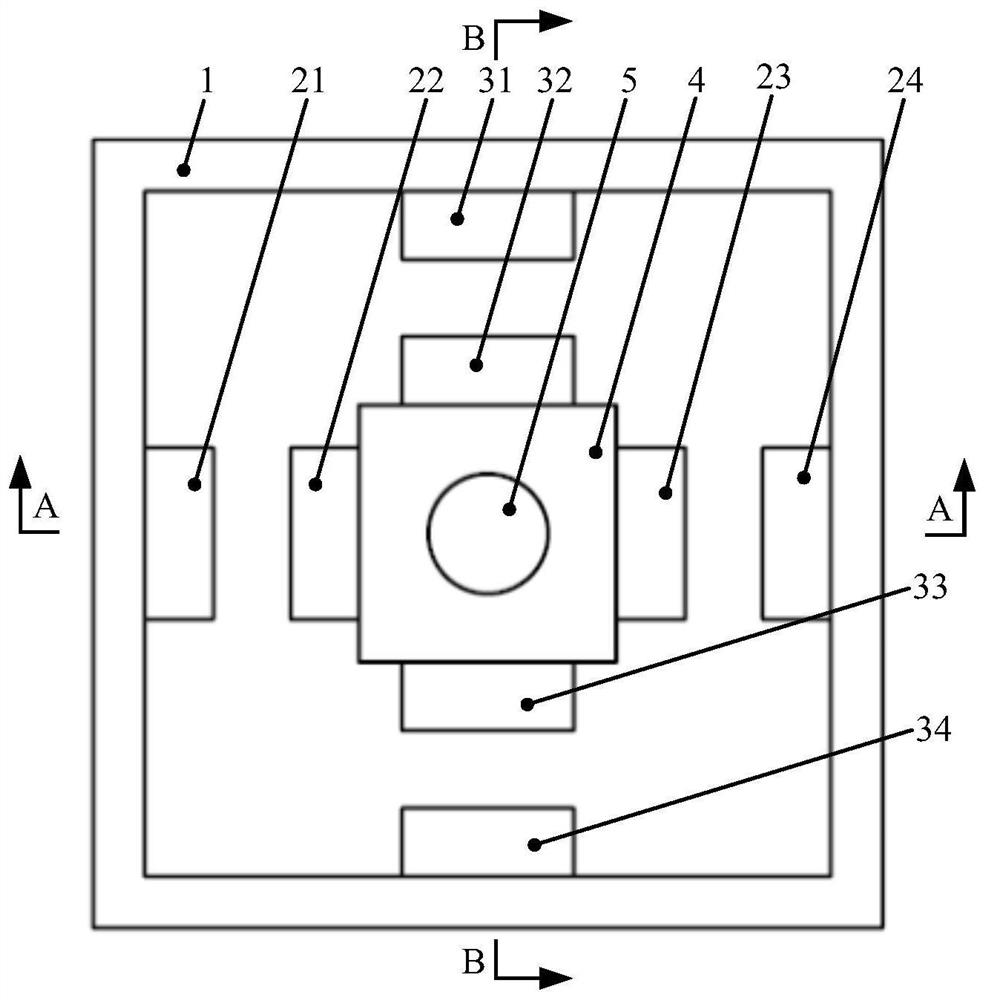

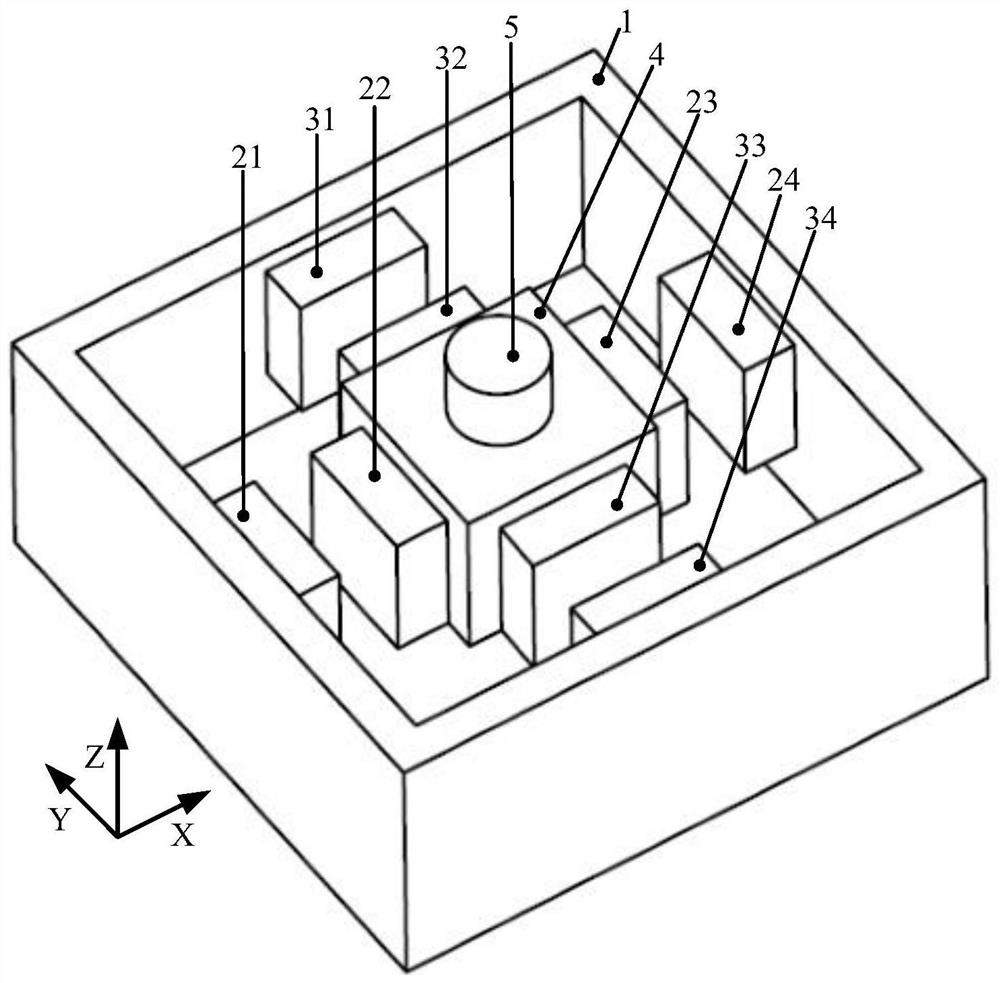

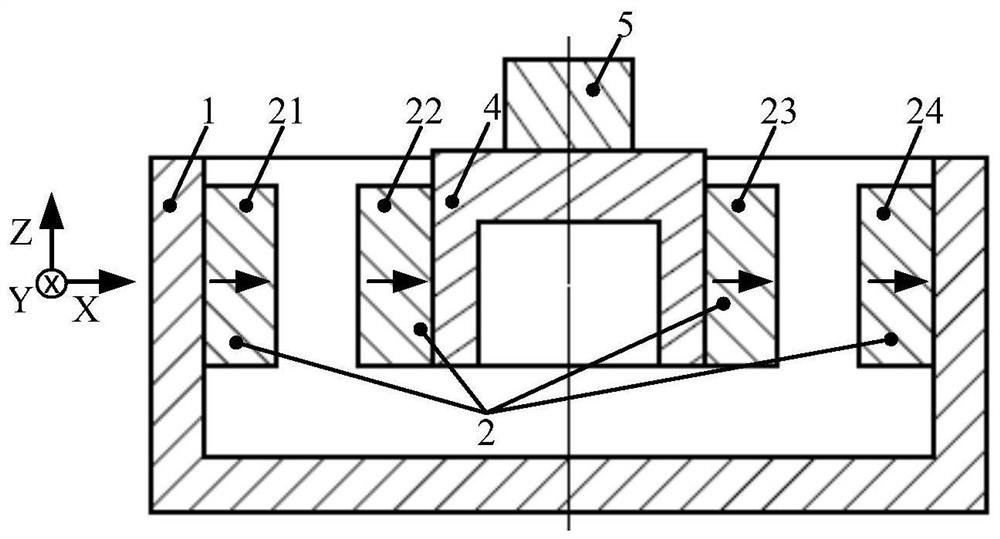

[0031] As a specific implementation manner, the third fixed magnet 31 , the third moving magnet 32 , the fourth moving magnet 33 and the fourth fixed magnet 34 are magnetized in the same direction along the horizontal Y axis.

[0032] As a specific implementation, the third fixed magnet 31, the third moving magnet 32, the fourth moving magnet 33 and the fourth fixed magnet 34 are all magnetized along the horizontal X-axis or Z-axis, and the third fixed magnet 31 The magnetization direction is the same as that of the fourth fixed magnet 34 , and opposite to the magnetization directions of the third moving magnet 32 and the fourth moving magnet 33 .

[0033] As a specific implementation, the overall structure of the horizontal two-degree-of-freedom electromagnetic vibration isolation device based on the parallel connection of positive and negative stiffnesses based on magnetic attraction is axisymmetric, and the fixing holes are square holes.

[0034] Combine below Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com