Optical fiber vibration measurement device and method with light source frequency shift calibration auxiliary channel

An auxiliary channel and optical fiber vibration technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of reducing the phase noise of lasers, and it is difficult to further improve the measurement accuracy of external vibration signals, so as to improve measurement accuracy and improve Measurement accuracy, effect of eliminating phase noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

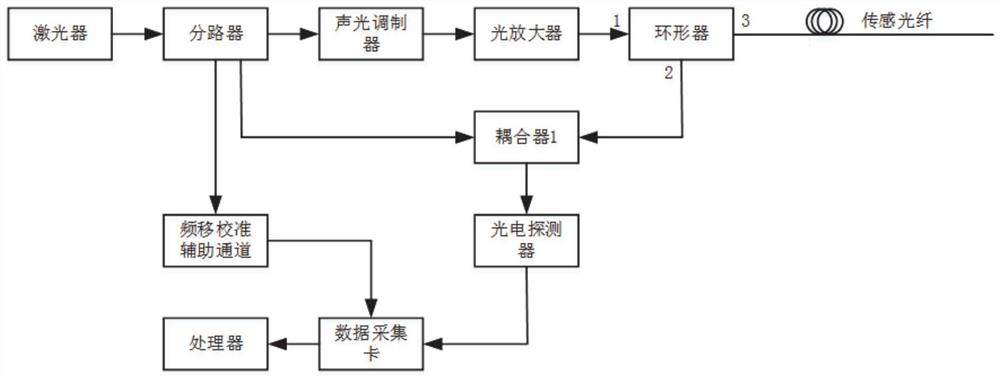

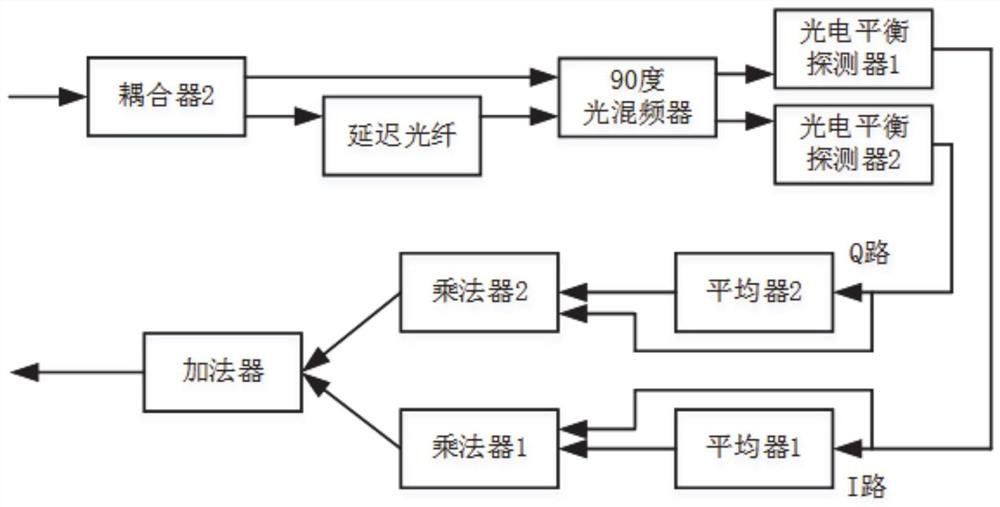

[0045] In a typical implementation of the present disclosure, such as Figure 1-Figure 2 As shown, a fiber optic vibration measurement device with an auxiliary channel for frequency shift calibration of the light source is proposed.

[0046] The device includes: laser, splitter, acousto-optic modulator, optical amplifier, circulator, sensing fiber, coupler 1, photodetector 1, frequency shift calibration auxiliary channel, photodetector 2, data acquisition card and processing device.

[0047] The laser emits narrow-linewidth continuous light, which is divided into 3 paths through a splitter, of which 1 path of continuous light passes through an acousto-optic modulator with a frequency shift function, converts it into pulsed light with a specific width and period, and then passes through an optical amplifier for power conversion. After compensation, it enters the 1 port of the circulator, and then enters the sensing fiber through the 3 port of the circulator, and obtains the vi...

Embodiment 2

[0055] In another typical embodiment of the present disclosure, as Figure 1-Figure 2 As shown, a fiber vibration measurement method with an auxiliary channel for frequency shift calibration of the light source is proposed.

[0056] Include the following steps:

[0057] The laser outputs continuous light with frequency v 0 +Δv 0 (t), v 0 Represents the ideal value of the light wave frequency, which is a constant, but due to the inevitable noise of the laser, the light wave frequency contains a frequency drift component Δv 0 (t), t represents time;

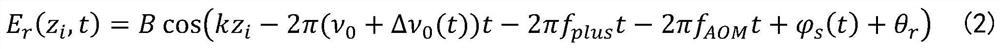

[0058] The continuous light of the laser is divided into 3 paths through the splitter, and the first path of continuous light passes through the acousto-optic modulator with frequency shift function, converts it into pulsed light with a specific width and period, and then enters the sensor through the optical amplifier and circulator. Optical fiber to obtain Rayleigh scattered light wave E r (z i , t), z i Indicates the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com