Double-stage ultrafine pulverizer

An ultra-fine pulverizer and coarse pulverizing technology, applied in grain processing and other directions, can solve the problems of poor pulverization particle size uniformity, large total energy consumption, large wear of hammer and ring gear, etc., to increase the pulverizing area and reduce the total energy. The effect of reducing consumption and total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

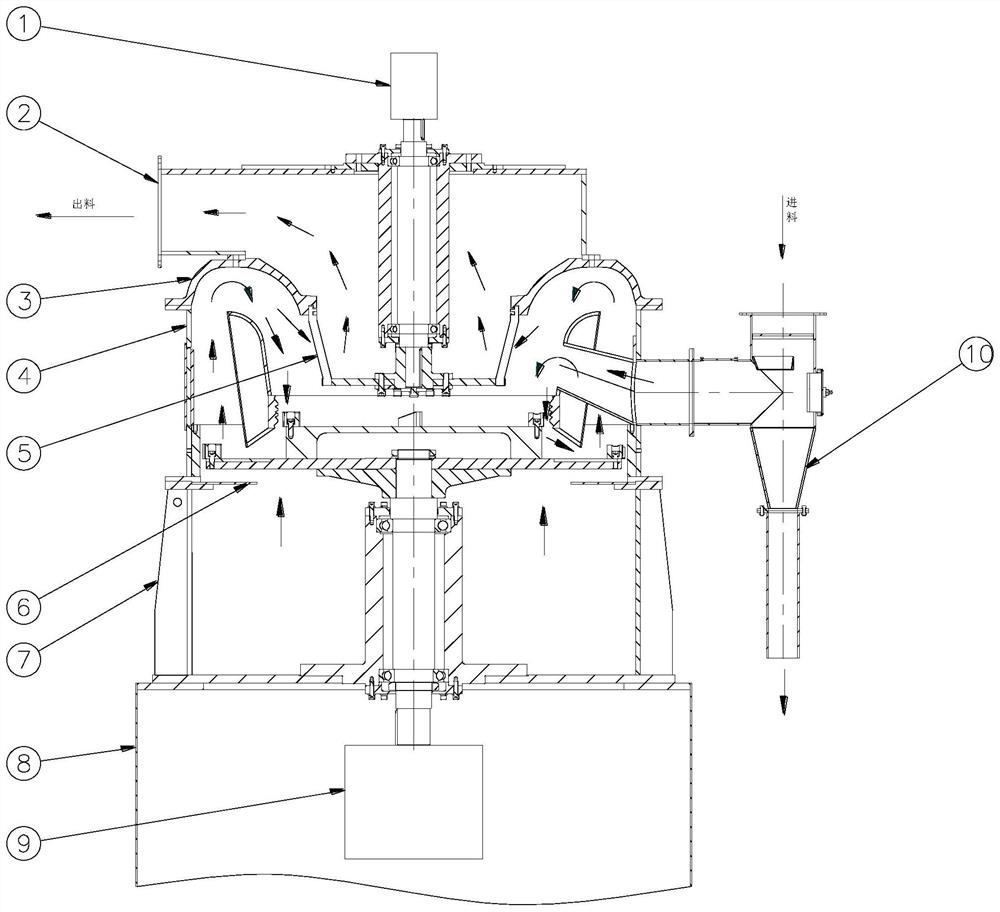

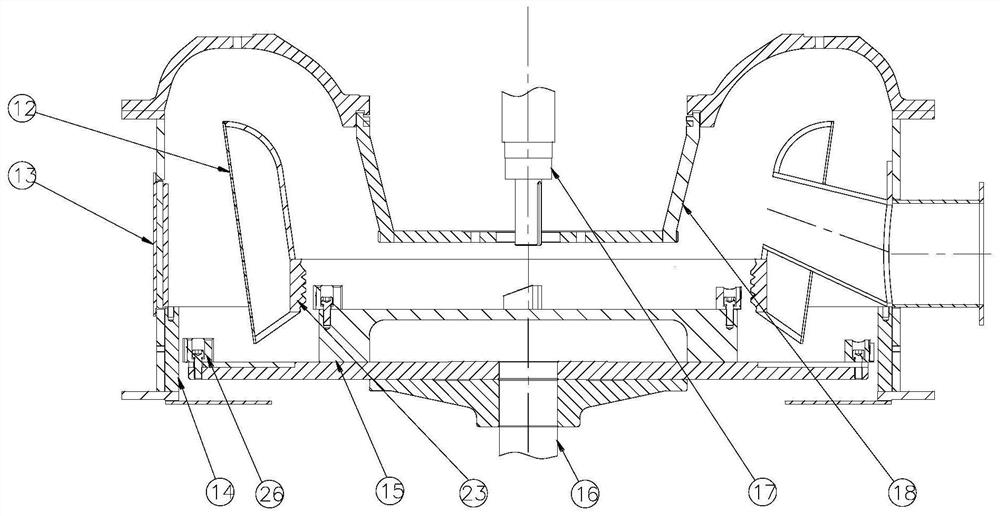

[0042] Such as figure 1 , 2 As shown, a two-stage ultrafine pulverizer includes a discharge chamber 2, a crushing system 4, an air transportation system, a classification system 5, a bottom bracket 8, and a feeding pipe 10.

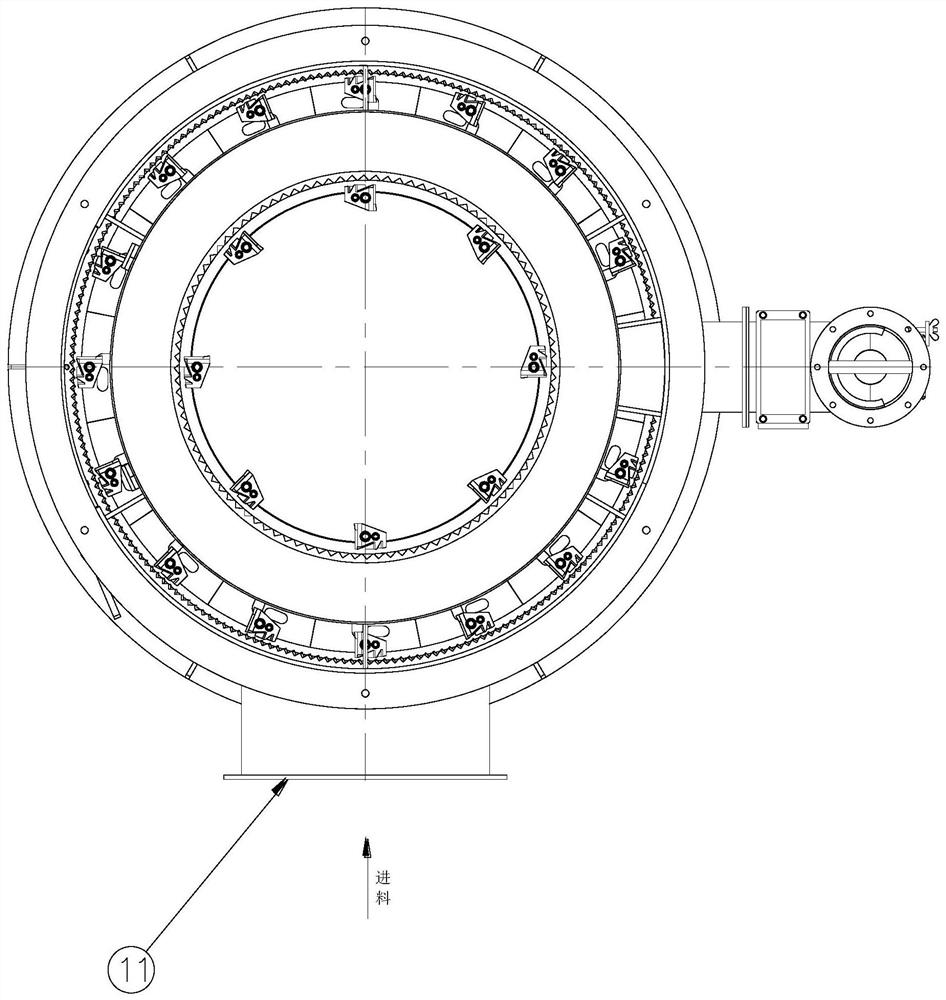

[0043] The top of the bottom bracket 8 is equipped with a clean air chamber 7, the air inlet 11 is located on the side of the clean air chamber 7, the top of the clean air chamber 7 is equipped with an assembled liner 6, and the top of the clean air chamber 7 is connected to the crushing system 4. The air purification chamber 7 and the air inlet 11 form a wind transportation system for material transportation between the crushing system 4 and the discharge chamber 2 . Assembled liner 6 is a circular ring as a whole, and is divided into six pieces, which are installed on the flange below the crushing system 4 through bolts, and can be disassembled and assembled through the inspection door of the purified air chamber 7 for easy replacement.

[0044] Such ...

Embodiment 2

[0057] The difference from Embodiment 1 is that the structure of the shunt hood 12 is different, and the shunt shroud 12 is a single-layer conical shroud structure. The lower part of the inner wall of the shunt cover 12 is provided with a coarse crushing ring gear 30 .

Embodiment 3

[0059] Such as Figure 10 As shown, the difference from Embodiment 1 is that the installation positions of the coarse crushing ring gear and the coarse crushing hammer knife 30 are different, the material movement track is different, the structure of the shunt cover 12 is different, and the structure of the feed pipe 10 is different.

[0060] The number of coarse crushing ring gears is two, including the first coarse crushing ring gear 37 and the second coarse crushing ring gear 38, which are arranged oppositely. The first coarse crushing ring gear 37 is arranged on the inner wall of the crushing system, and the second coarse crushing ring gear 38 It is arranged on the outer wall of the shunt cover 12.

[0061] The fine crushing ring gear 14 is arranged on the inner wall of the crushing system.

[0062] The hammer knife mounting plate comprises a crushing support plate 28, a crushing chassis 27, and the crushing support plate 28 is installed on the top of the crushing system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com