A pepper separation device capable of automatically cleaning sieve holes and its separation method

A technology for automatic cleaning and separation equipment, applied in solid separation, chemical instruments and methods, filter screens, etc., can solve problems such as inconvenient cleaning of screen holes, achieve high cleaning efficiency and screening reliability, sufficient screening, and easy assembly. and the effect of repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

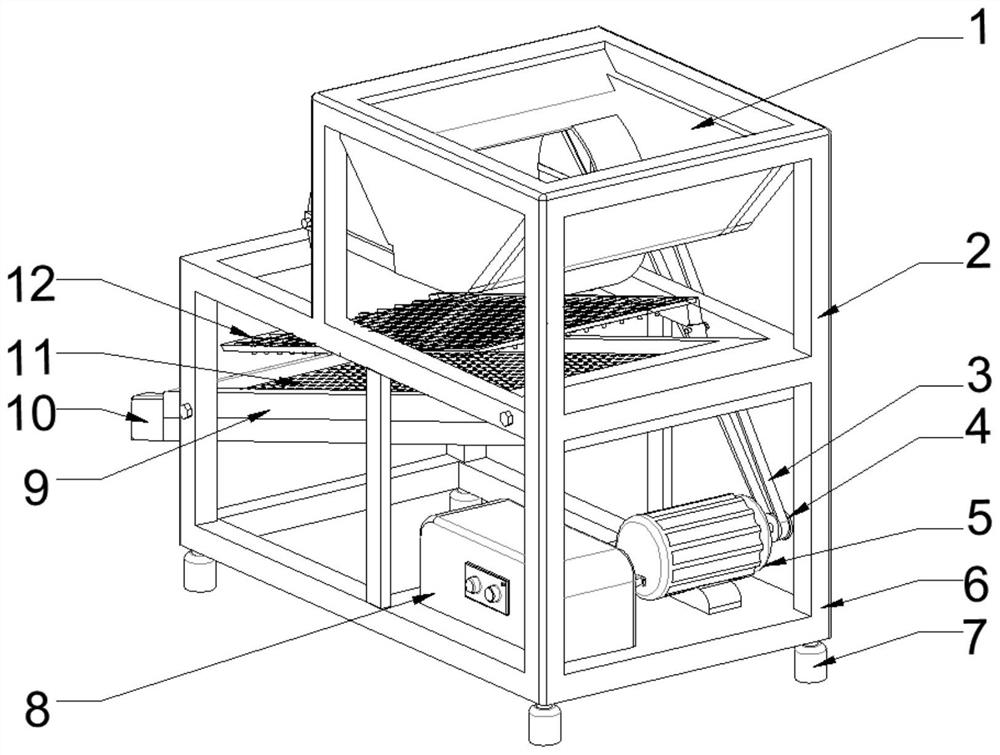

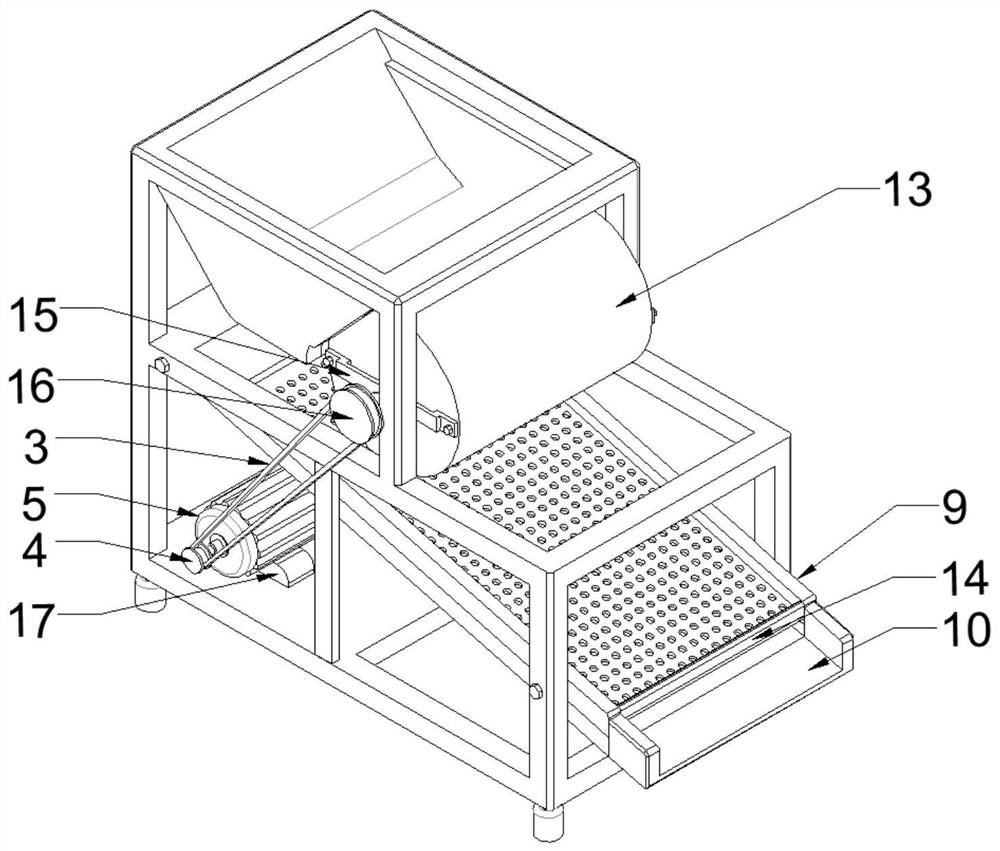

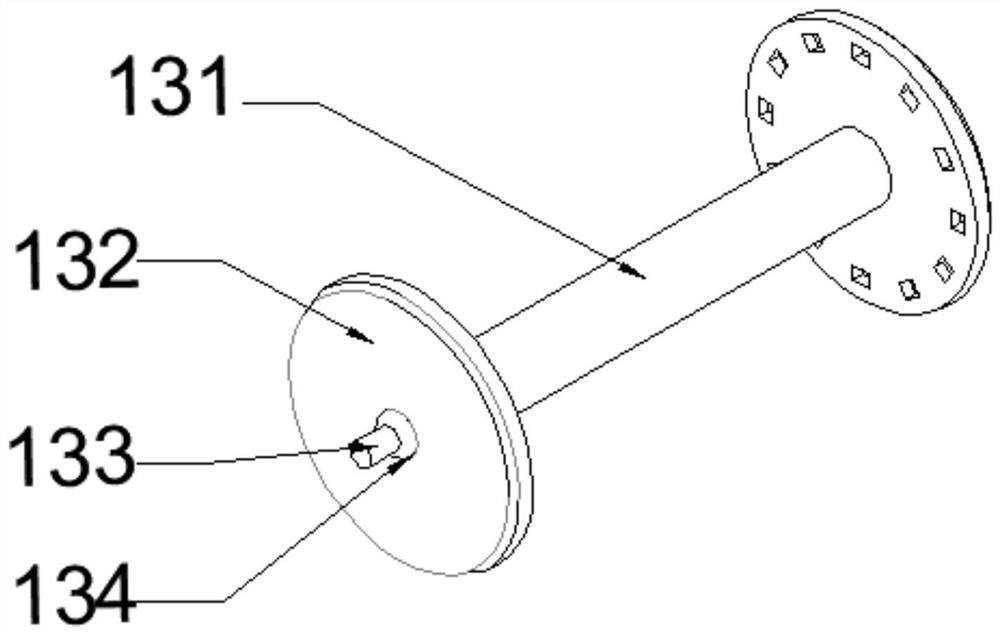

[0031] Such as figure 1 , 2 Shown in and 3, a kind of pepper separation equipment that can automatically clean the sieve holes includes a body, a feed channel 1, a motor 5, a separation cylinder 13, a cleaning part 12 and a screening device; as an embodiment, the body includes an upper Frame 2 and lower frame 6, upper frame 2 is fixed on the top of lower frame 6; Feed channel 1 is fixed on the body, and separation occurs cylinder 13 is placed in the outlet of feed channel 1; As a preferred embodiment, feed Channel 1 is an inverted trapezoid, so that the material slides to the separation cylinder 13; the separation cylinder 13 includes an outer cylinder, a rotating shaft 131, a shaft plate 132, a supporting shaft 133 and a separation extrusion part 135; The two fixing parts 15 are respectively fixed; the fixing parts 15 are fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com