Curtain coating cooling and producing devices and methods

A technology of cooling device and cooling method, applied in production device and method device, casting cooling field, can solve problems such as insufficient film crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

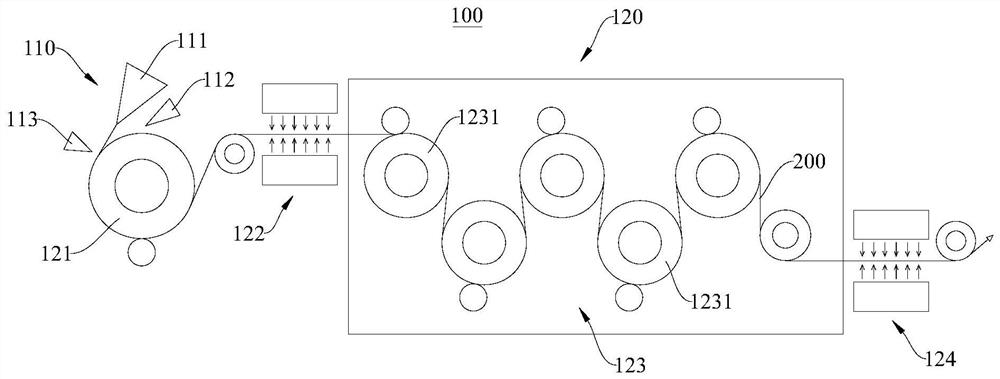

[0080] A casting production method, comprising: extruding a casting melt; casting the extruded melt on a cooling roll 121 for cooling and shaping to obtain a cast film 200; The first air cooling treatment is performed; then the cast film 200 is heat treated in the heat treatment unit 123 ; and the cast film 200 is subjected to the second air cooling treatment in the second air cooling unit 124 .

[0081] in:

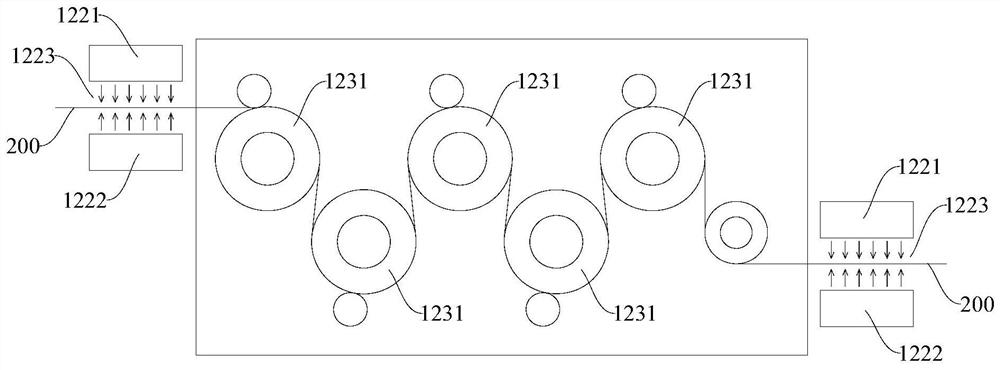

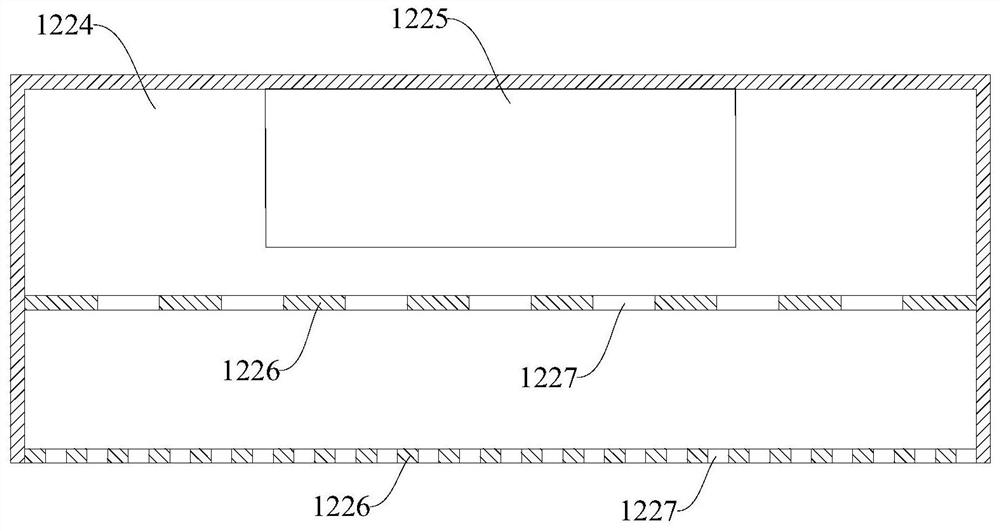

[0082] Each air-cooled processing unit includes a first cold air assembly 1221 and a second cold air assembly 1222, and a first partition and a second partition are arranged at intervals in the air outlet channel of each air cooling assembly along the air outlet direction, and the first partition The distance between the plate and the second partition is 10 cm, the diameter of the outlet hole 1227 of the first partition is 2 mm, and the diameter of the outlet hole 1227 of the second partition is 10 mm. Five sets of heating guide rollers 1231 are arranged in the heat tre...

Embodiment 2

[0088] A casting production method, which differs from Example 1 in that:

[0089] The cast film 200 is a PP film with a thickness of 12 μm, and the overall speed of the film is 120 m / min.

[0090] In the first air-cooling treatment, the treatment temperature is 30°C and the wind speed is 2-3m / s.

[0091] In the heat treatment, the temperature of the first set of heating guide rollers 1231 is 110°C, and the increment of the speed ratio between the rolls is +0.3%; the temperature of the second set of heating guide rollers 1231 is 130°C, and the increment of the speed ratio between the rolls is +0.2% The temperature of the third group of heating guide rollers 1231 is 129°C, and the increment of the speed ratio between the rollers is +0.2%; the temperature of the fourth group of heating guide rollers 1231 is 125°C, and the increment of the speed ratio between the rollers is 0%; the fifth The temperature of the set of heated guide rollers 1231 is 105°C, and the increment of the spe...

Embodiment 3

[0094] A casting production method, which differs from Example 1 in that:

[0095] The cast film 200 is a PP film with a thickness of 23 μm, and the overall speed of the film is 90 m / min.

[0096] In the first air-cooling treatment, the treatment temperature is 20°C and the wind speed is 4-5m / s.

[0097] In the heat treatment, the temperature of the first set of heating guide rollers 1231 is 100°C, and the increment of the speed ratio between the rolls is +0.4%; the temperature of the second set of heating guide rollers 1231 is 110°C, and the increment of the speed ratio between the rolls is +0.3% The temperature of the third group of heating guide rollers 1231 is 120°C, and the increment of the speed ratio between the rollers is +0.2%; the temperature of the fourth group of heating guide rollers 1231 is 100°C, and the increment of the speed ratio between the rollers is -0.3%; The temperature of the five sets of heated guide rollers 1231 is 80°C, and the increment of the spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com