Incense stamping machine with packing function

A kind of aroma pressing machine and functional technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of chaotic placement of incense, increased labor intensity, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

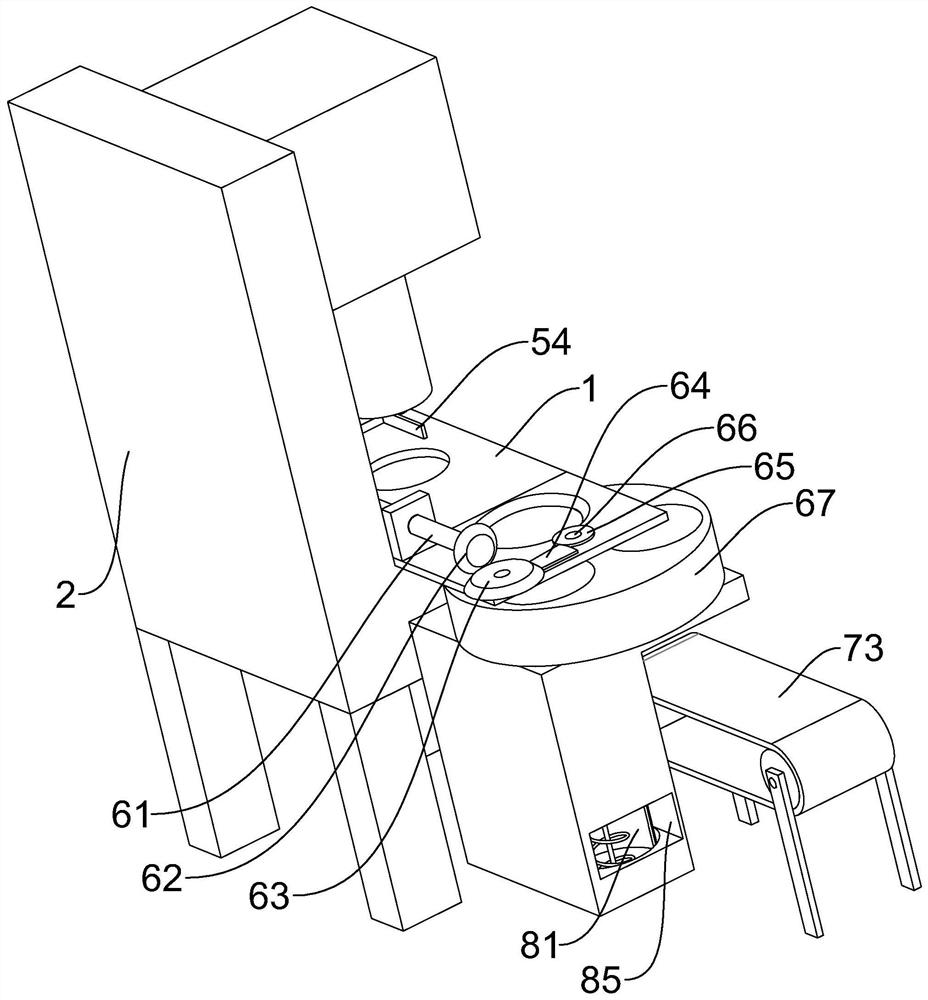

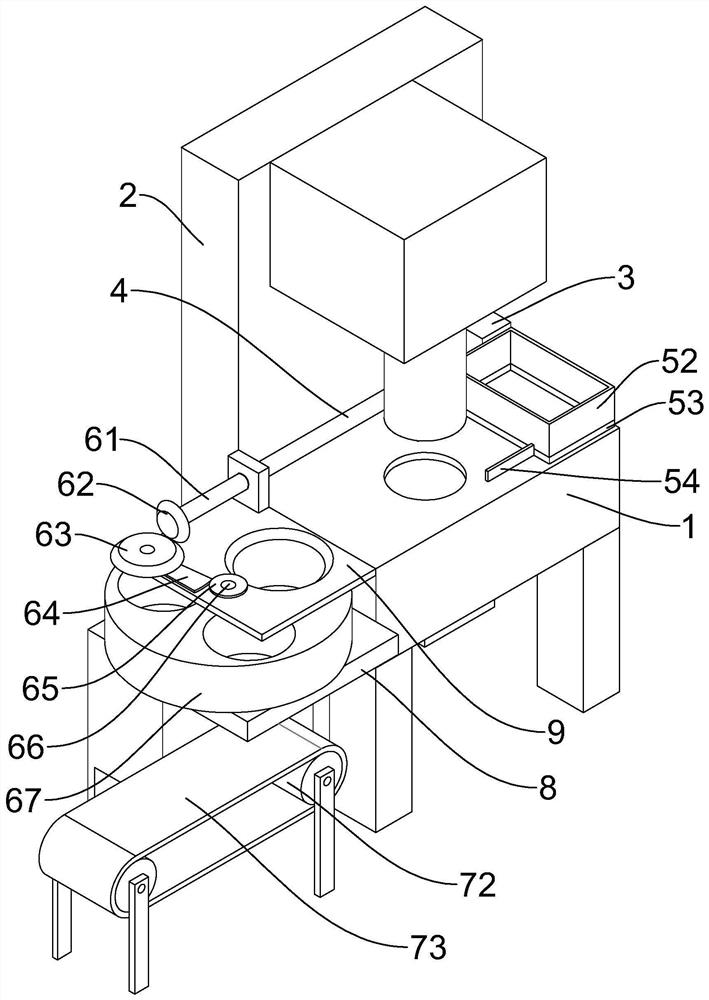

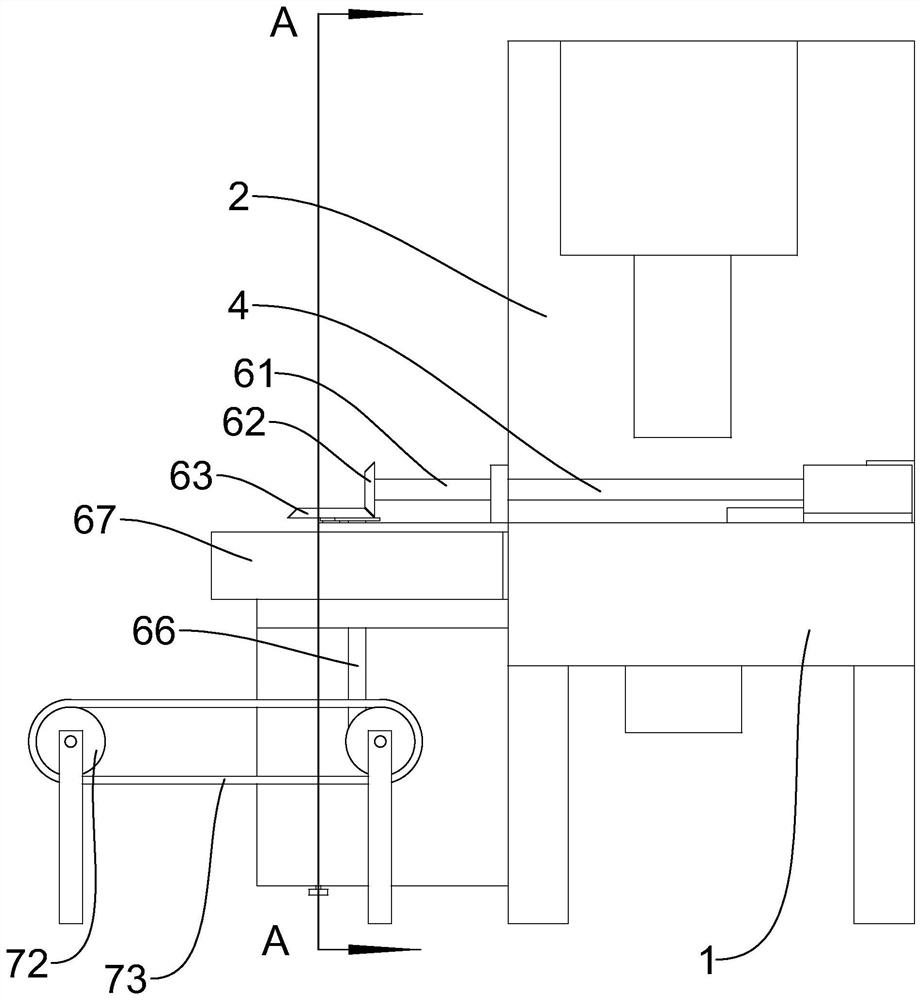

[0025] like Figure 1 to Figure 9 As shown, a kind of aroma pressing machine with box packing function includes a machine base 2 and a workbench 1 arranged on the machine base 2, a stepper motor 3 is arranged on the back side of the upper end of the workbench 1, and the output of the stepper motor 3 A reciprocating screw 4 arranged horizontally is keyed on the shaft, and a powder adding mechanism 5 for adding powder to the stamping groove of the work table 1 and pushing out the pressed incense is provided on the worktable 1, and the powder adding mechanism 5 is connected with the reciprocating screw 4, The base 2 is matched, the left end of the workbench 1 is provided with an L-shaped firm block 8, the left end of the workbench 1 is provided with an extension block 9 flush with the upper surface of the workbench 1 and positioned above the firm block 8, and the reciprocating screw The left end of 4 is connected with the rotary mechanism 6 that is used for the fragrance packing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com