Wire feeding mechanism of steel bar binding machine and steel bar binding machine

A technology of wire feeding mechanism and bundling machine, which is applied in building construction, building material processing, construction, etc., can solve the problems of unstable looping drift, looping failure, and inability to realize automation stably and effectively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

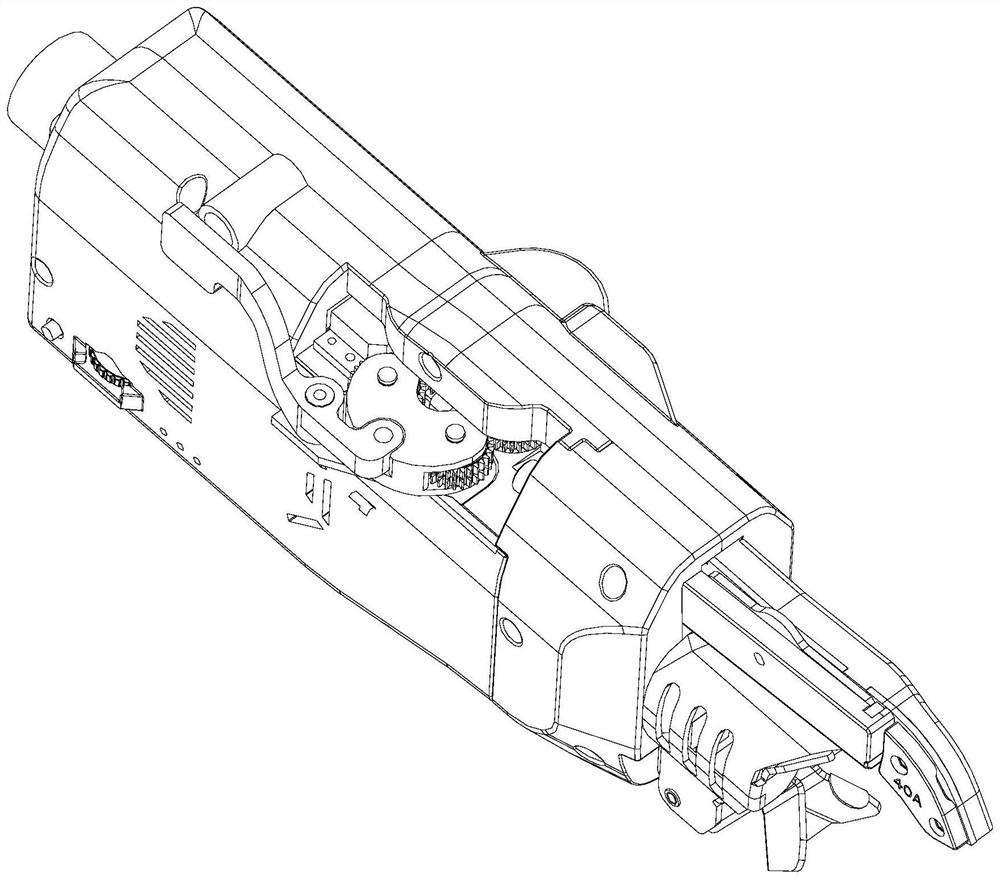

[0045] A wire feeding mechanism of a steel bar binding machine in this embodiment, such as Figure 6-8 As shown, the wire feeding mechanism includes a transmission mechanism and two groups of wire feeding wheels arranged along the feeding direction of the wire binding. Each group of wire feeding wheels jointly clamps the binding wire and transmits it. The wire wheel and a driven wire feed wheel, when the same group of active wire feed wheels and driven wire feed wheels are meshed, they form a conveying groove that can bite and transmit the wire, and the transmission mechanism drives the active wire feed wheels of each group of wire feed wheels to rotate synchronously .

[0046] The wire feeding mechanism of the steel bar binding machine in this embodiment is used for the single wire transmission of large rolls of wires in automation equipment, that is, two groups of wire feeding wheels jointly convey one wire.

[0047]Specifically, the wire feed rollers of the wire feed mecha...

Embodiment 2

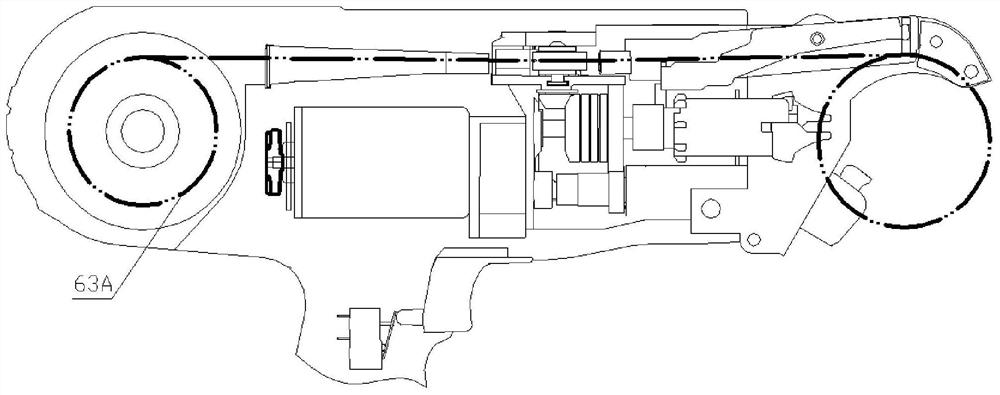

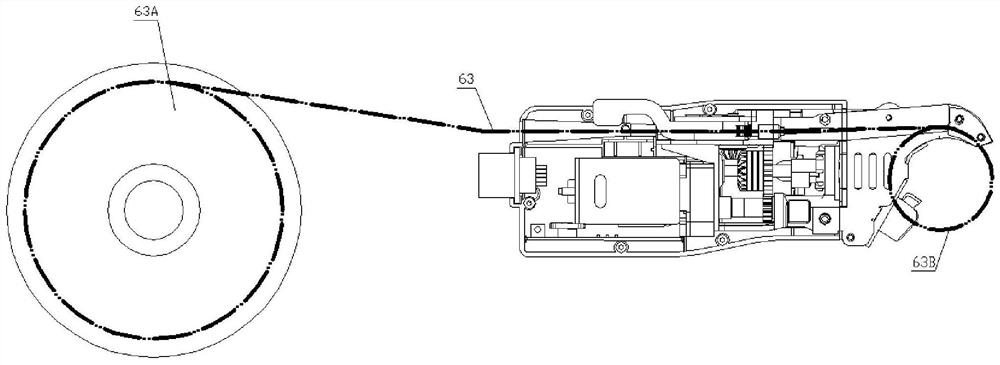

[0057] This embodiment is a steel bar binding machine, comprising the wire feeding mechanism of the steel bar binding machine described in Embodiment 1. The wire feeding mechanism of the steel bar binding machine is installed on the main body. Such as Figure 2-7 As shown, it is a schematic diagram of the steel bar binding machine of the present invention used in automation equipment to use a large-volume binding coil. The binding wire of the large-volume binding coil 63A is wound in a wire reel, and finally passes through the wire feeding mechanism of the steel bar binding machine to bind the steel bar. The binding region of the machine forms the wire binding circle 63B of the binding steel bar. Depend on figure 1 with figure 2 It can be seen that the steel bar binding machine used by the automation equipment and the large coil wire coil used therein are very different from the existing steel bar binding machine and its application.

Embodiment 3

[0059] This embodiment is a wire feeding mechanism of a steel bar binding machine. Compared with Embodiment 1, the difference is that in this embodiment, two sets of wire feeding wheels simultaneously transmit two wires paralleled horizontally or vertically. That is to say, two groups of wire feeding wheels are arranged in the direction orthogonal to the wire binding conveying direction, and convey the two wire bindings paralleled horizontally or vertically.

[0060] Such as Figure 11a As shown, each group of wire feed wheels occludes and conveys the horizontally juxtaposed binding wires 63, and the cross-sectional shape of the transmission groove coincides with the arrangement of the binding wires, as shown in Figure 11b As shown, each set of wire feed wheels bites and conveys the vertically juxtaposed binding wires 63 , and the cross-sectional shape of the transmission groove matches the arrangement of the binding wires. Therefore, each group of wire feeding wheels can po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com