Intermittent printing apparatus

A technology for printing presses and printing units, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of damage to the printed substrate, printing dirt, easy deviation and relaxation of the printed substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Preferred Mode for Carrying Out the Invention

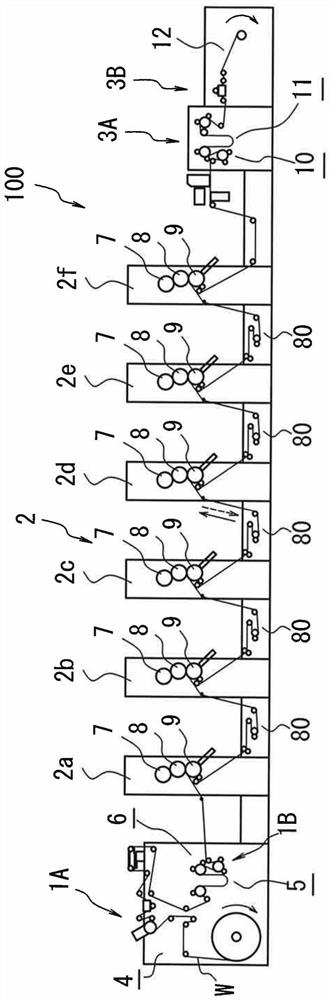

[0081] based on figure 1 The overall basic structure of the intermittent printing machine of the present invention will be described. figure 1 It is the whole front view of the intermittent printing machine which concerns on embodiment of this invention.

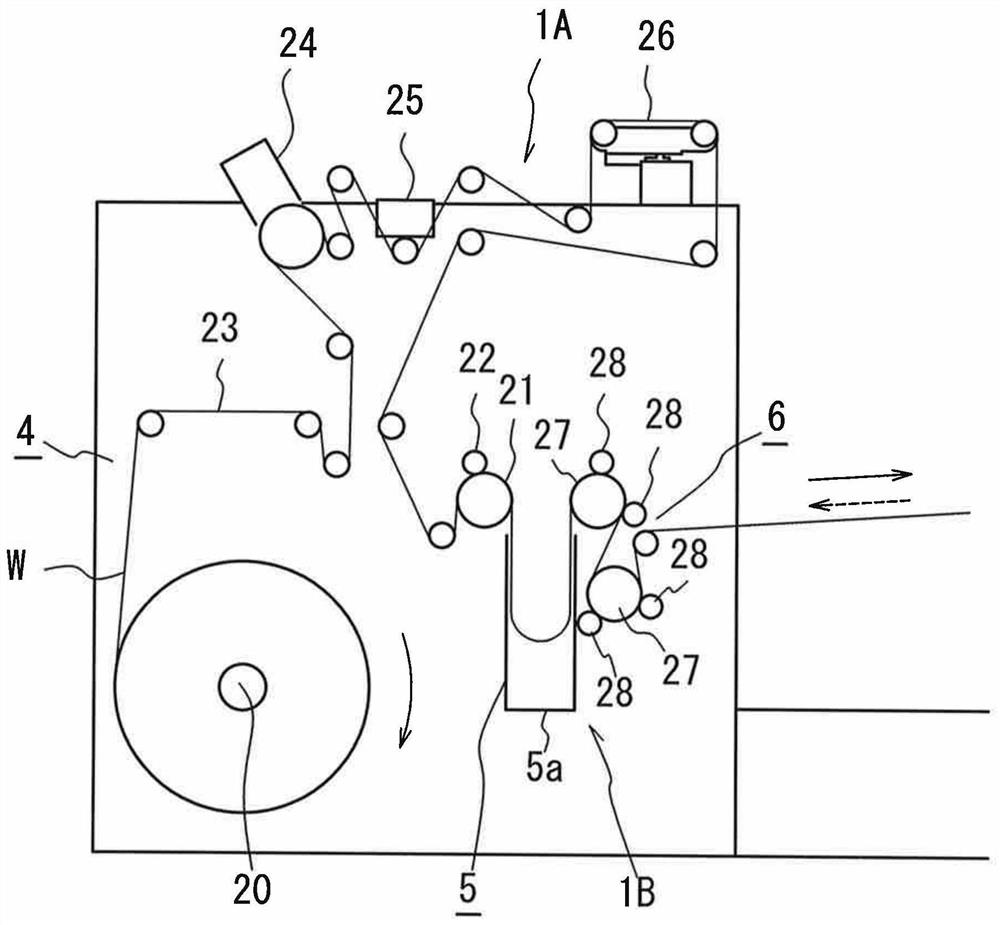

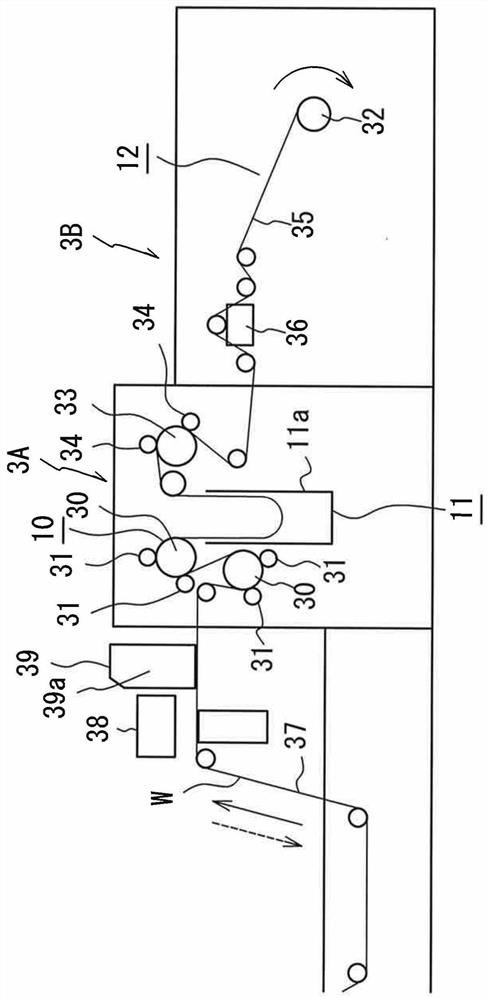

[0082] The intermittent printing machine 100 has a paper feeder 1A that supplies the printed substrate W; a paper feeder 1B that feeds the printed base W that is supplied from the paper feeder 1A; The printing section 2 on the substrate W; the paper discharge section 3A that discharges the printed substrate W on which the image is printed (hereinafter simply referred to as the printed substrate W); and performs post-processing on the printed substrate W The post-processing section 3B.

[0083] The substrate W to be printed used in the batch printing machine 100 of this embodiment is a flexible film with a high surface smoothness. For example, use raw materials for fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com