A stern shaft disassembly tool and a stern shaft disassembly method

A technology for dismantling tooling and stern shaft. It is used in safety devices, transportation and packaging, load hanging components, etc. It can solve the problems of cutting the binding tape, damage to the contact surface, axial sliding, etc., to avoid rigid contact and self-weight. Light, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

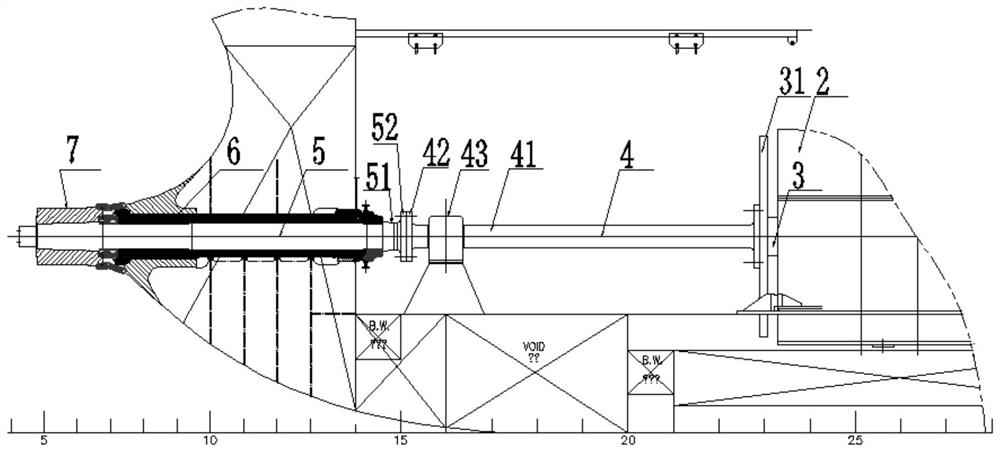

[0034] Please refer to Figure 4-6 , Figure 4 It is a schematic diagram of the structure of the tie rod described in Embodiment 1 of the present invention, Figure 5 It is a schematic structural diagram of the stern shaft disassembly tooling according to Embodiment 1 of the present invention, Image 6 It is a schematic diagram of the assembly structure of the stern shaft disassembly tooling according to Embodiment 1 of the present invention.

[0035] As shown in the figure, Embodiment 1 of the present invention provides a stern shaft disassembly tool 1, which includes a pull rod 11, a protective cover 12 and two lifting snap rings 13; the pull rod 11 includes a pull rod body 112 and a pull rod body 112. The tie rod lifting lug 114; the tie rod body 112 is detachably penetrated in the stern shaft flange hole 53 of the stern shaft to be disassembled; the protective sleeve 12 is sleeved on the tie rod body 112, and is located between the tie rod body 112 and the stern shaft fl...

Embodiment 2

[0041] Please refer to Figure 7 , Figure 7 It is a schematic diagram of the assembly structure of the stern shaft disassembly tooling according to Embodiment 2 of the present invention. As shown in the figure, Embodiment 2 of the present invention provides a stern shaft disassembly tool, which is different from Embodiment 1 in that it further includes a gasket 60; The first protection section 121 and the second protection section 122 fixed on one end of the body of the protective cover 12. The outer diameter of the first protection section 121 matches the inner diameter of the stern shaft flange hole 53 of the stern shaft to be disassembled, and its length is different. greater than the length of the stern shaft flange hole 53 of the stern shaft to be disassembled; the outer diameter of the second protection section 122 is larger than the outer diameter of the first protection section 121, and abuts with the stop flange 116; the gasket 60 is sleeved on the tie rod The body...

Embodiment 3

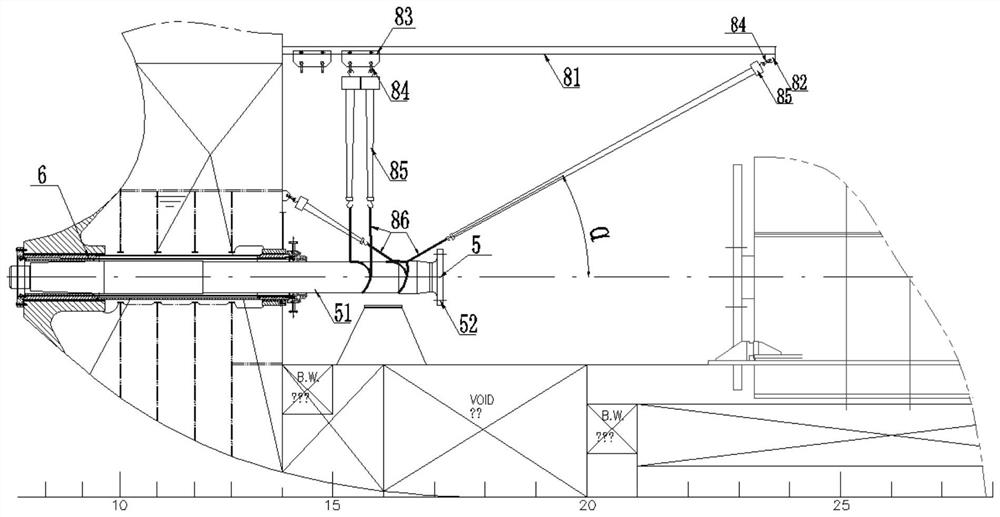

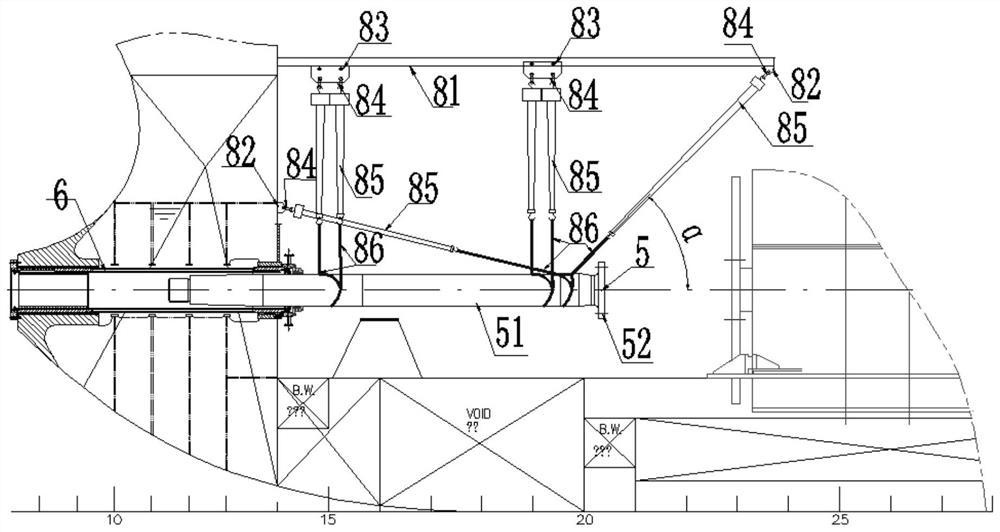

[0045] Please refer to Figure 8-9 , Figure 8 Schematic illustration of the disassembly process of the stern shaft disassembly method according to Embodiment 3 of the present invention Figure 1 , Figure 9 Schematic illustration of the disassembly process of the stern shaft disassembly method according to Embodiment 3 of the present invention Figure II . Embodiment 3 of the present invention provides a stern shaft disassembly method, which uses the above-mentioned stern shaft disassembly tool for disassembly, and specifically includes the following steps:

[0046] 1) Remove the connecting bolts (not shown) between the stern shaft flange 52 and the intermediate shaft flange 42 of the stern shaft to be disassembled, remove the intermediate shaft 4 and lift the intermediate shaft 4 away with a crane;

[0047] 2) A moving track 81 is arranged on the hull just above the stern shaft 5 along the pull-out direction of the stern shaft 5; a moving trolley 83 is slidably arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com