Preparation process of trifluoromethanesulfonic anhydride

A technology of trifluoromethanesulfonic anhydride and trifluoromethanesulfonic acid, which is applied in the field of trifluoromethanesulfonic anhydride preparation technology, can solve the problem of multiple trifluoromethanesulfonic acid salt steps, reduce the preparation efficiency, and improve the overall yield of trifluoromethanesulfonic anhydride No high problems, to reduce time consumption, simplify the preparation process, improve efficiency and overall yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

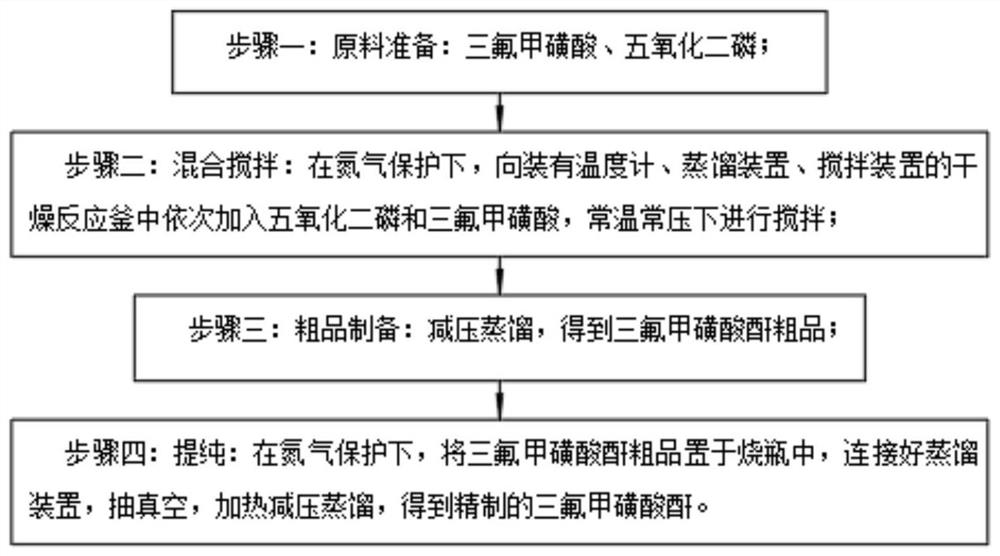

[0024] see figure 1 , the present invention provides a kind of technical scheme: a kind of trifluoromethanesulfonic anhydride preparation process comprises the steps:

[0025] Step 1: raw material preparation: trifluoromethanesulfonic acid, phosphorus pentoxide; the dosage of trifluoromethanesulfonic acid is 1.0 times of phosphorus pentoxide; trifluoromethanesulfonic acid generates viscous phosphoric acid after being dehydrated by phosphorus pentoxide Esters, part of trifluoromethanesulfonic anhydride doped in it, can not be evaporated, resulting in low overall yield, the amount of trifluoromethanesulfonic acid is 1.0 times that of phosphorus pentoxide, which helps to improve the overall yield;

[0026] Step 2: Mixing and stirring: under the protection of nitrogen, add phosphorus pentoxide and trifluoromethanesulfonic acid in sequence to the dry reaction kettle equipped with a thermometer, a distillation device and a stirring device. The reaction temperature is 20°C, which hel...

Embodiment 2

[0031] see figure 1 , the present invention provides a kind of technical scheme: a kind of trifluoromethanesulfonic anhydride preparation process comprises the steps:

[0032] Step 1: raw material preparation: trifluoromethanesulfonic acid, phosphorus pentoxide; the amount of trifluoromethanesulfonic acid is 1.4 times that of phosphorus pentoxide; trifluoromethanesulfonic acid generates viscous phosphoric acid after dehydration of phosphorus pentoxide Esters, part of the trifluoromethanesulfonic anhydride doped therein, can not be evaporated, resulting in a low overall yield, the amount of trifluoromethanesulfonic acid is 1.4 times that of phosphorus pentoxide, which helps to improve the overall yield;

[0033] Step 2: Mixing and stirring: under the protection of nitrogen, add phosphorus pentoxide and trifluoromethanesulfonic acid in turn to the dry reaction kettle equipped with a thermometer, a distillation device and a stirring device. The reaction temperature is 25 °C, whic...

Embodiment 3

[0038] see figure 1 , the present invention provides a kind of technical scheme: a kind of trifluoromethanesulfonic anhydride preparation process comprises the steps:

[0039] Step 1: raw material preparation: trifluoromethanesulfonic acid, phosphorus pentoxide; the amount of trifluoromethanesulfonic acid is 1.8 times that of phosphorus pentoxide; trifluoromethanesulfonic acid generates viscous phosphoric acid after dehydration of phosphorus pentoxide Esters, part of trifluoromethanesulfonic anhydride doped therein, can not be evaporated, resulting in low overall yield, the amount of trifluoromethanesulfonic acid is 1.8 times of phosphorus pentoxide, which helps to improve the overall yield;

[0040] Step 2: Mixing and stirring: under the protection of nitrogen, add phosphorus pentoxide and trifluoromethanesulfonic acid in sequence to the dry reaction kettle equipped with a thermometer, a distillation device and a stirring device. The reaction temperature is 30 °C, which helps...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap