Float-process microalgae culture system

A technology of microalgae cultivation and floatation, applied in the direction of microorganisms, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of increased construction volume, many welding points, and poor fixation, so as to reduce water volatilization and reduce Effect of temperature control and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

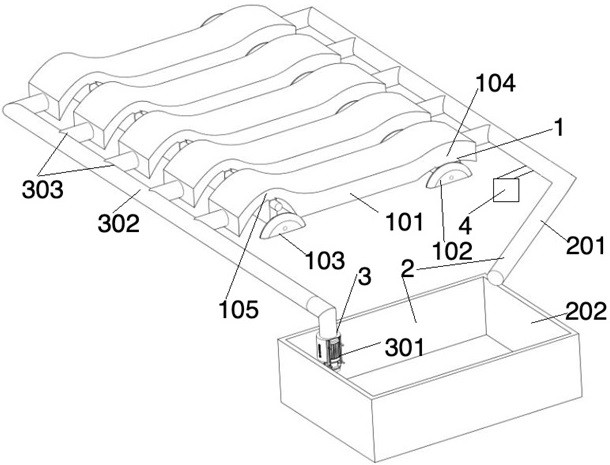

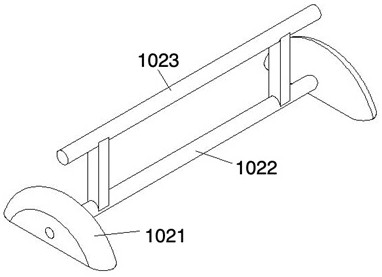

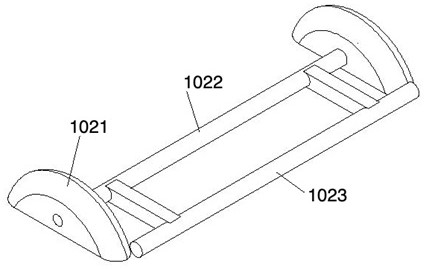

[0028] as attached Figures 1 to 8As shown, the microalgae culture system includes a culture unit 1, a buffer unit 2, a circulation unit 3, and an aeration unit 4, wherein the culture unit 1 is one or more flexible transparent cylinders 101 laid substantially horizontally side by side, and the flexible transparent cylinders The lower side of the inlet end 105 of 101 is padded with a first backing plate 103, and the lower side of the outlet end 104 is padded with a second backing plate 102. The first backing plate 103 is higher than the second backing plate 102, generally 5-10 centimeters higher. When the two ends of the flexible transparent tube 101 are placed on the first backing plate 103 and the second backing plate 102 respectively, a tank chamber capable of accommodating culture fluid and microalgae will be formed inside the flexible transparent tube 101, and the flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com