Automatic doffing system of spinning yarn coiling machine

A winding machine, automatic technology, applied in textile and papermaking, bundling of newly ejected filaments, etc., can solve the problems of time-consuming, labor-intensive, inconvenient, manual operation, etc., to shorten the interval time, improve the efficiency, and improve the work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

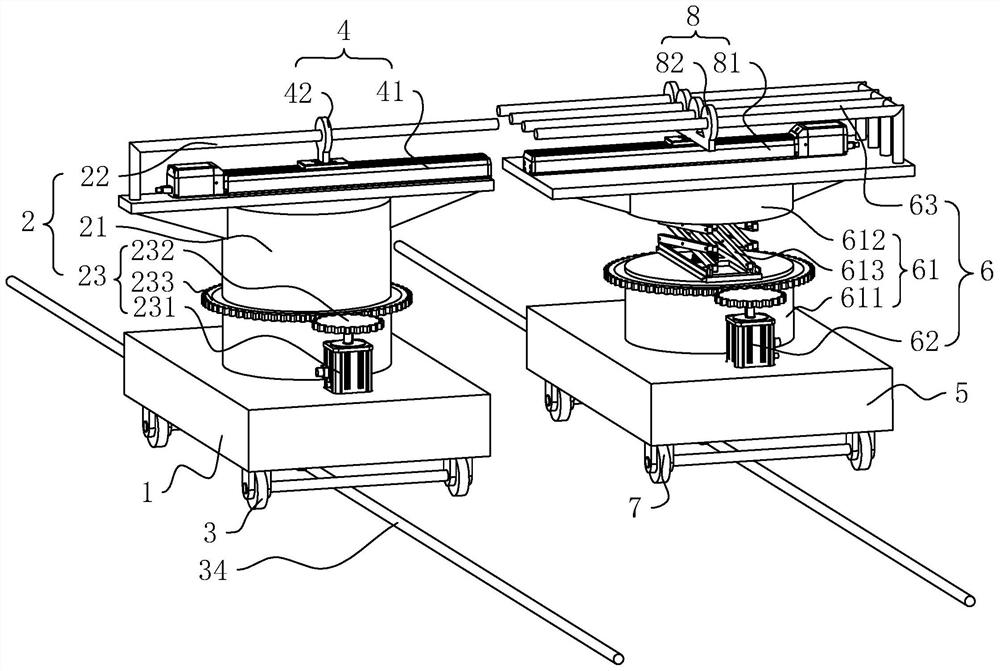

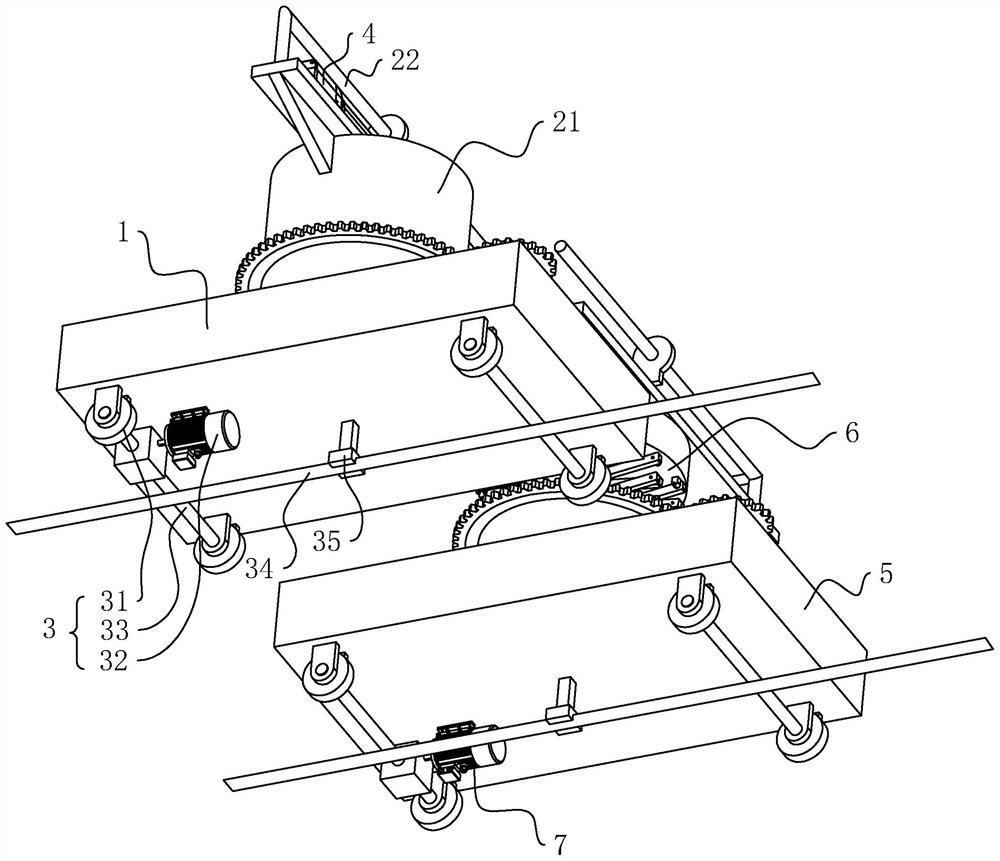

[0038] The following is attached Figure 1-2 The present invention is described in further detail.

[0039] The embodiment of the present application discloses an automatic doffing system of a spinning winding machine. refer to figure 1The automatic doffing system of the spinning winder includes an automatic take-up device for taking out the wire coil from the spinning winder and a storage device for storing the wire coil; the automatic take-up device includes a first base 1, A take-up mechanism 2 arranged above the first base 1 and a first traction mechanism 3 arranged below the first base 1 . When the winding of the spinning winder is completed, the finished coil will be pushed onto the take-up mechanism 2, and the first traction mechanism 3 can drive the automatic take-up device to have one side of the spinning winder move to On the side of another spin winder to facilitate removal of coils from different spin winders.

[0040] refer to figure 1 , the storage device in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap