Bearing vibration monitoring system

A monitoring system, a technology for bearing vibration, used in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as poor bearing operating conditions, bearing damage, etc., to reduce maintenance costs, prevent unexpected downtime, Avoid damaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

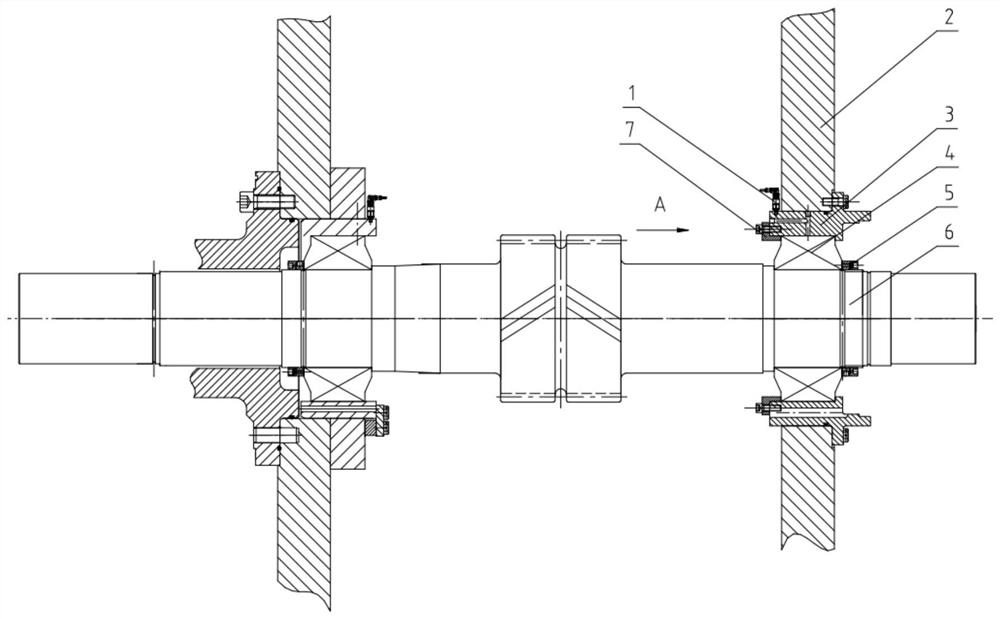

[0014] figure 1 The above is a schematic diagram of installation of the vibration sensor of the present invention.

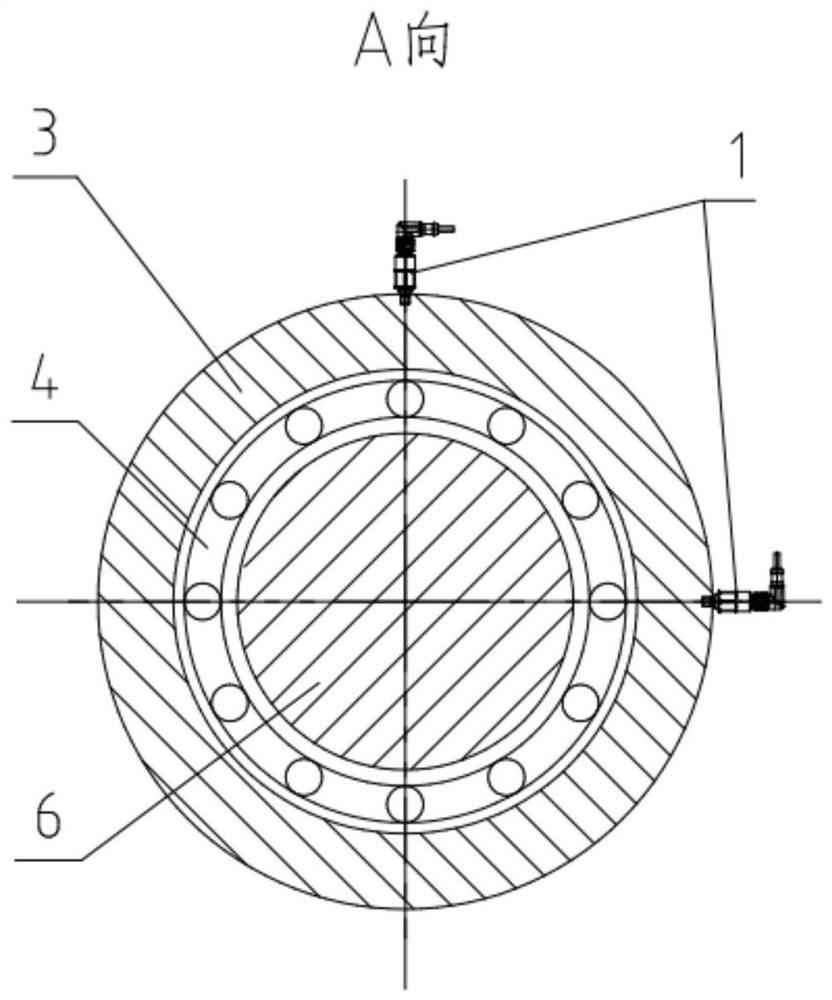

[0015] figure 2 described as the present invention figure 1 The schematic diagram of A direction.

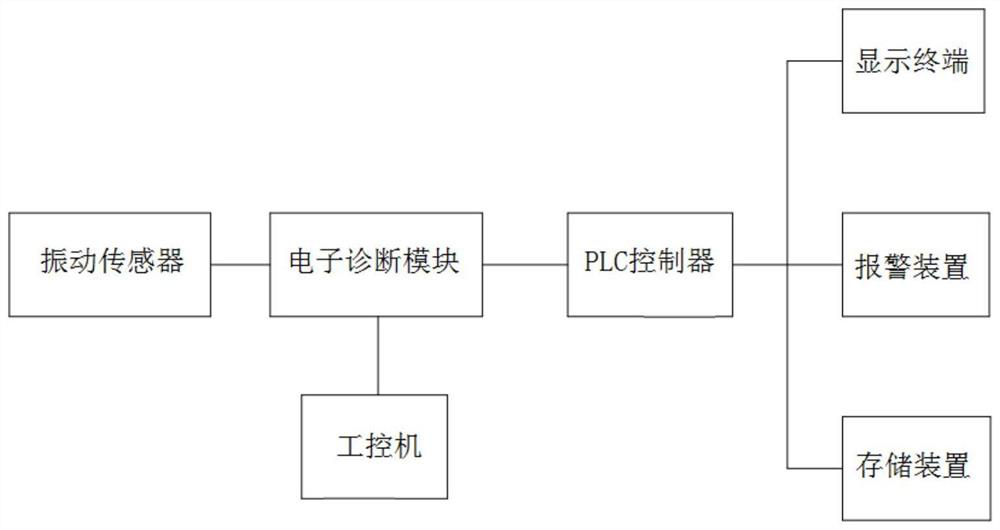

[0016] image 3 Described is a structural block diagram of the present invention.

[0017] The present invention provides a bearing vibration monitoring system, which includes a bearing 4, a support sleeve 3, a vibration sensor 1, an electronic diagnostic module 8, an industrial computer 9, a PLC controller 10, a display terminal 11, an alarm device 12 and a storage device 13. The above bearing 4 is installed on the gear shaft 6 with interference fit, the bearing 4 and the gear shaft 6 are installed in the inner hole of the support sleeve 3, and the vibration sensor 1 is installed in the horizontal direction and the vertical dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com