Bipolar plate structure and fuel cell

A bipolar plate and unipolar plate technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve the problems of uneven gas distribution and the inability to effectively enlarge the area of the reaction zone, and achieve the number of flow channels. Uniform, wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

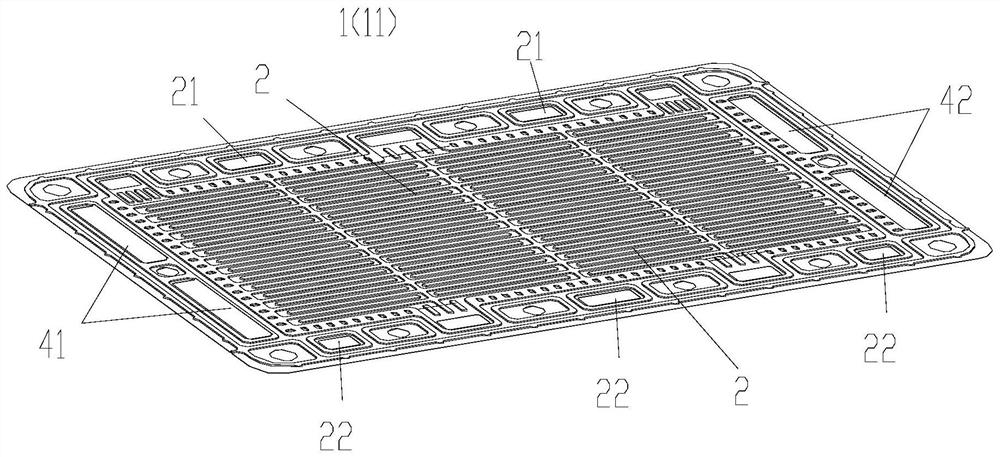

[0073] The pattern mentioned in the specific embodiment above needs to open two molds to punch out two patterns, A and B, and then overlap the positional relationship to form a smooth gas and cooling water inlet and outlet.

[0074] Under the condition that the basic flow field structure remains unchanged, the present invention can also be designed as a single-mold double-plate structure, and two bipolar plates can be punched out with a pair of dies, which can improve production efficiency.

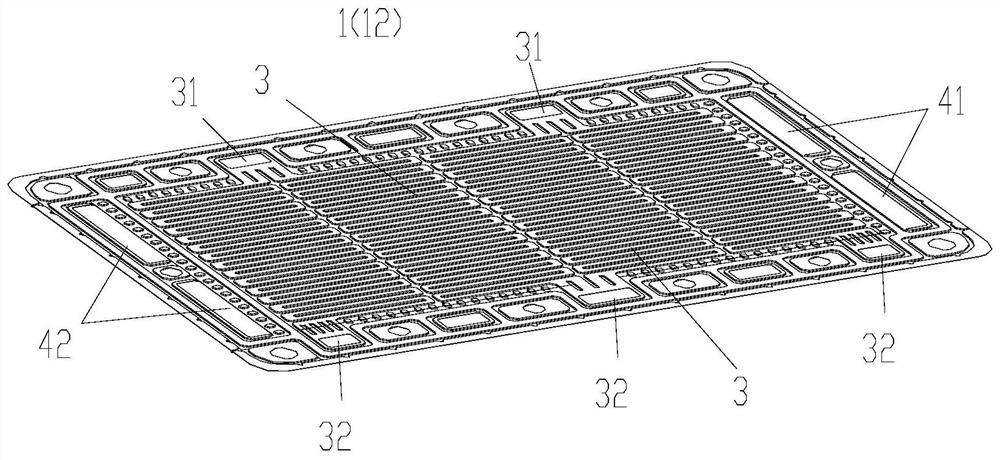

[0075] Such as Figure 8 It is version 2 of one mold and two plates, the overall flow field of the bipolar plate and the arrangement of gas inlet and outlet remain unchanged, and the layout of the cooling water inlet channel is changed to achieve the effect of one mold and two plates.

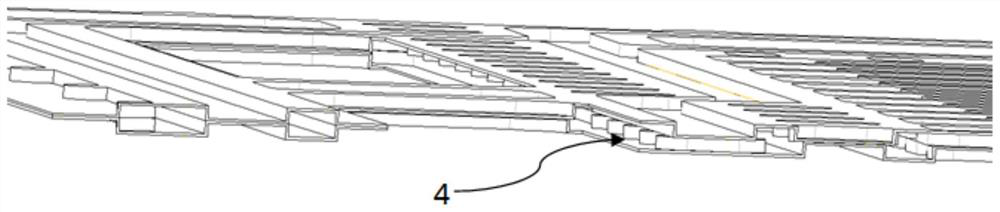

[0076] Since the cooling water channel support and sealing groove structure in version 2 are in a symmetrical relationship, when the bipolar plates are rotated and spliced by 180°, two sealant groove str...

Embodiment 2

[0080] Such as Figure 9 , adjust the positional relationship of the sealing rubber strip, and add a bolt hole at each of the four corners to ensure that the entire bipolar plate can be locked evenly after being pressed. The processing difficulty of the stamping die increases the strength of the whole support.

Embodiment 3

[0082] Such as Figure 10-11 , the present invention changes the pattern to the following way on the basis of replacing the second embodiment, moves the bolt holes to the outside of the pattern, maintains the strength of the overall structure of the pattern, and simultaneously designs four new ones on the upper and lower sides of the pattern The surrounding positioning groove structure is used for the surrounding positioning method of the metal bipolar plate during the assembly and stacking process. The surrounding positioning method can avoid the trouble of pulling out the positioning pin caused by positioning the positioning hole when the bipolar plate is stacked and pressed. The surrounding positioning grooves can also be used for fixing the bipolar plate on the fuel cell stack after assembly, so as to prevent the misalignment of the bipolar plate during the use of the fuel cell stack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com