Method and system for monitoring hidden faults of power grid power supply equipment

A technology for hidden faults and power supply equipment, applied in fault location, information technology support system, fault detection according to conductor type, etc., can solve problems such as unpredictable fault point, limited application of power supply equipment, and inability to install a large number of sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

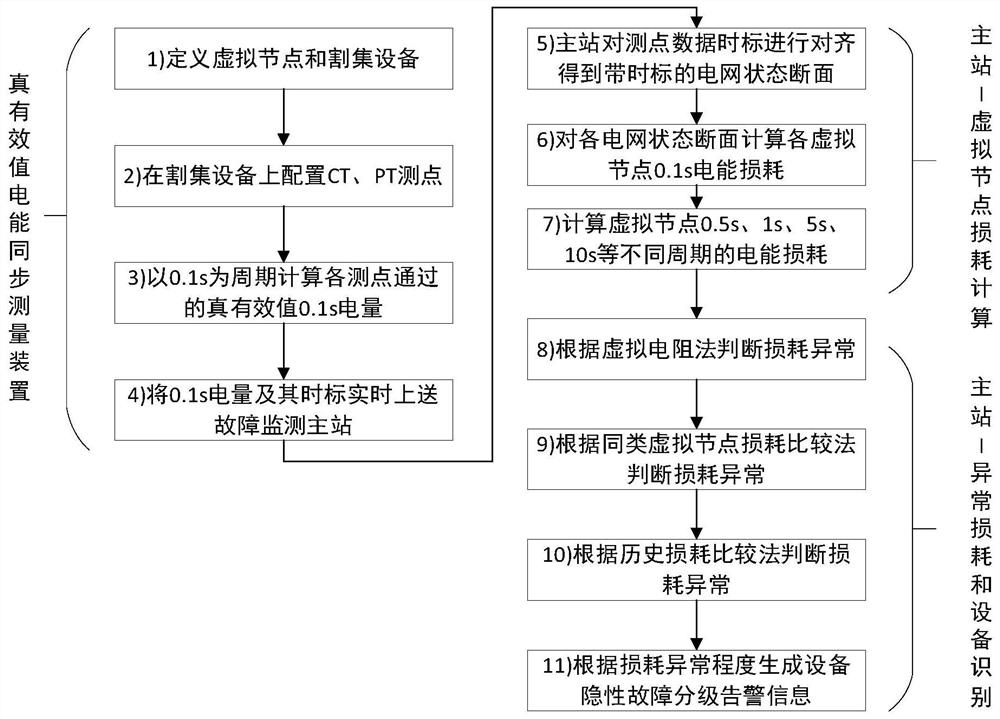

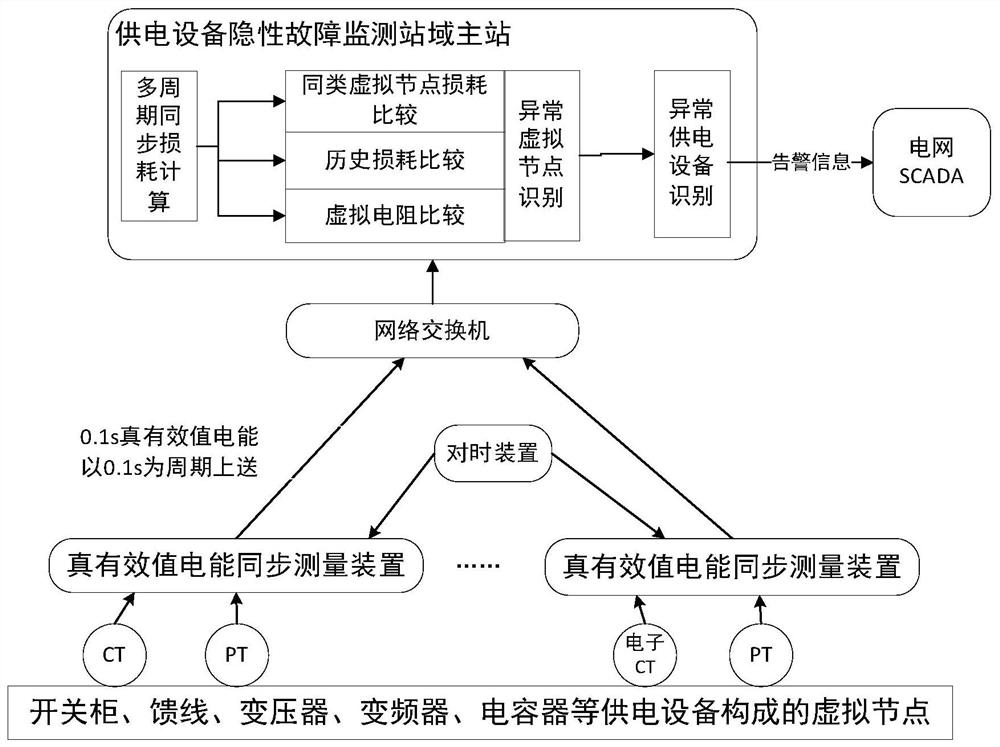

[0072] attached Figure 4 It is an example of a part of the one-line diagram of a 6kV / 0.4kV substation. In the figure, 401, 402, 403, and 404 are the numbers of the corresponding branch circuit switch cabinets. The figure also exemplarily draws a remote place powered by cables motor load. Operators hope to timely discover faults such as poor contact, discharge, insulation breakdown, etc. Timely detection and early warning of internal or external faults of power supply equipment such as transformers and capacitors. Embodiments of the method and system disclosed in this patent are as follows:

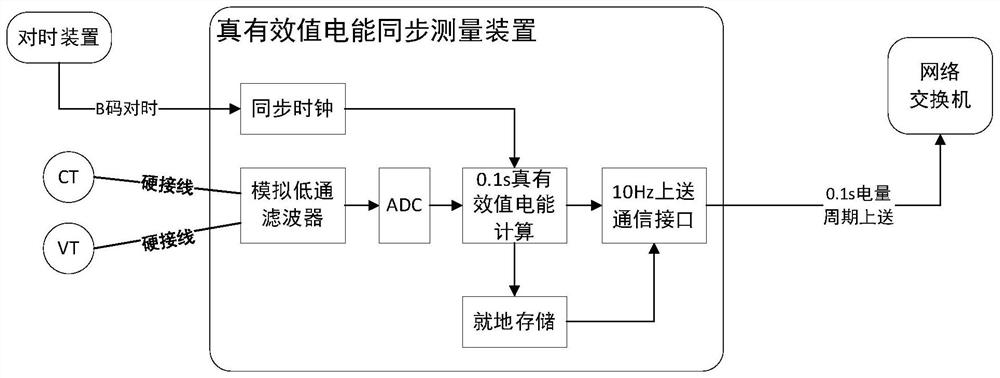

[0073] attached figure 1 Shown is a schematic flowchart of a method for monitoring hidden faults of power supply equipment based on the measurement of true effective value of electric energy loss disclosed in the present invention. The method for monitoring hidden faults of power supply equipment includes the following steps.

[0074] Step 1: Define a virtual node and a set of cut-set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com