Umbrella rib manufacturing method

A manufacturing method and technology of umbrella ribs, which are applied in the direction of walking sticks, etc., can solve problems such as damage to the electroplating layer, easy cracking of the electroplating layer, and affecting the normal use of umbrella ribs, and achieve the effects of stable electroplating layer, improved cleanliness, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

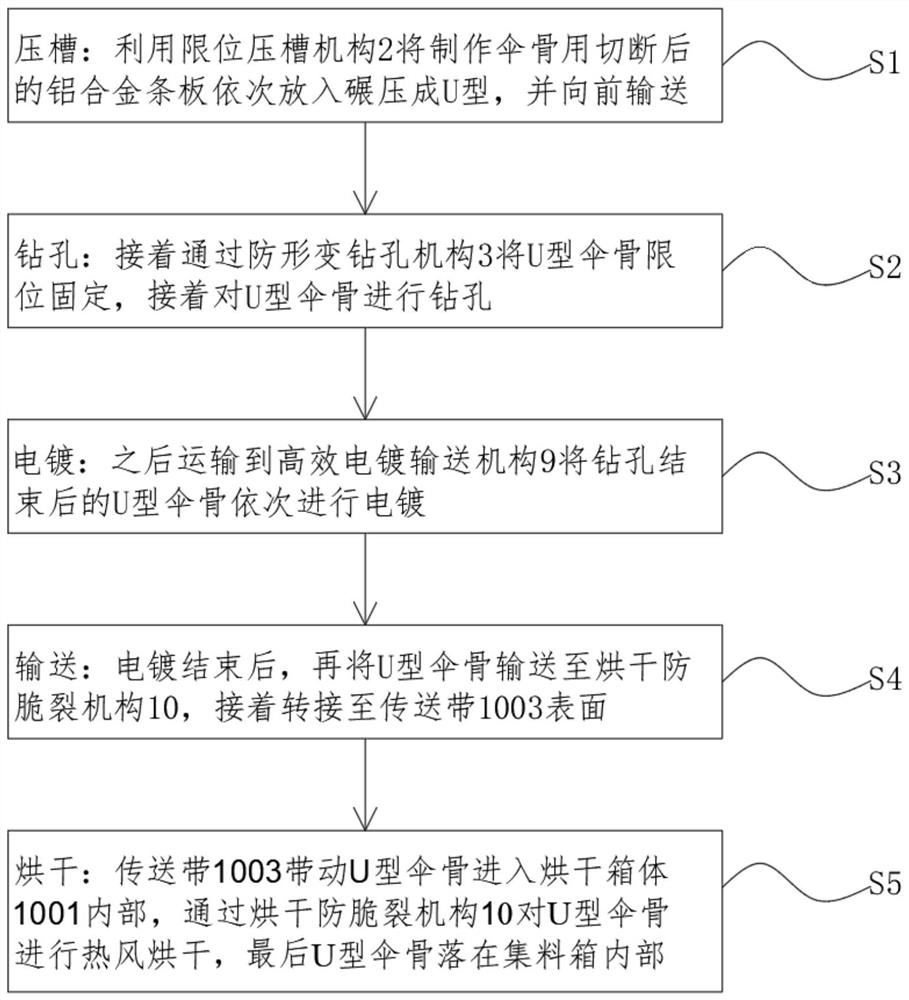

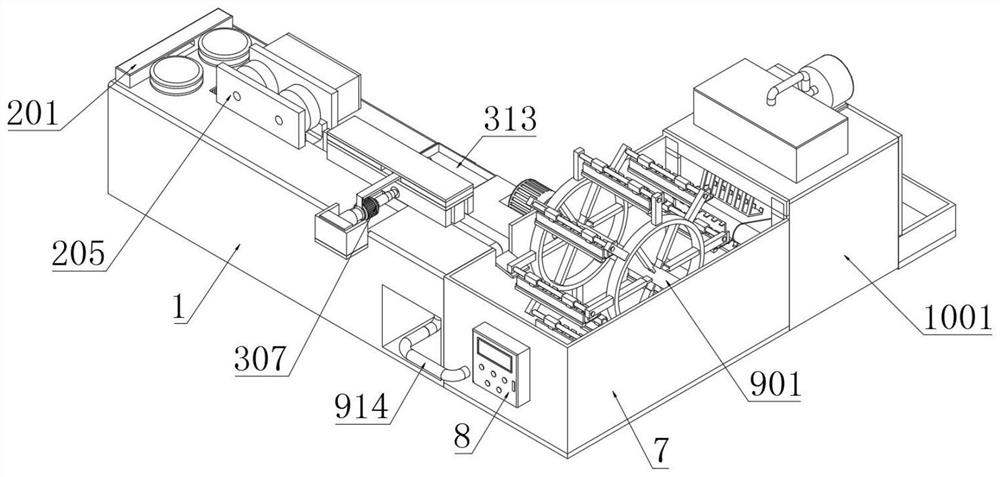

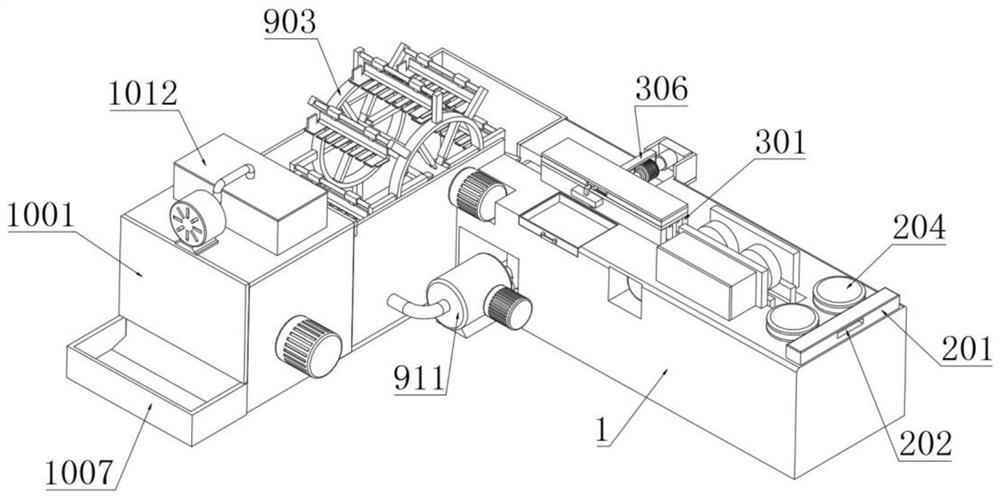

[0042] Example: such as Figure 2-10 As shown, the present invention provides a technical solution, a method for manufacturing umbrella ribs. One end of the top of the processing platform 1 is fixedly installed with a limit pressure groove mechanism 2, which acts as a limit support for the U-shaped umbrella ribs. The processing platform 1 An anti-deformation drilling mechanism 3 is fixedly installed at the end of the top away from the limit pressure groove mechanism 2 to ensure that the U-shaped ribs will not be squeezed and deformed during the drilling process. The top of the processing platform 1 is located under the anti-deformation drilling mechanism 3 The conveying shaft 4 is symmetrically and fixedly installed at the center, the surface of the conveying shaft 4 is sleeved with a conveying belt 5, one end of a conveying shaft 4 is fixedly connected with a conveying motor 6, and the middle part of the processing platform 1 is fixedly installed at the end far away from the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com