Steel plate processing system

A processing system and steel plate technology, applied in metal processing equipment, manufacturing tools, workpiece heating devices, etc., can solve problems such as difficulty in heating, and achieve the effects of improving service life, improving yield, and avoiding excessive movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

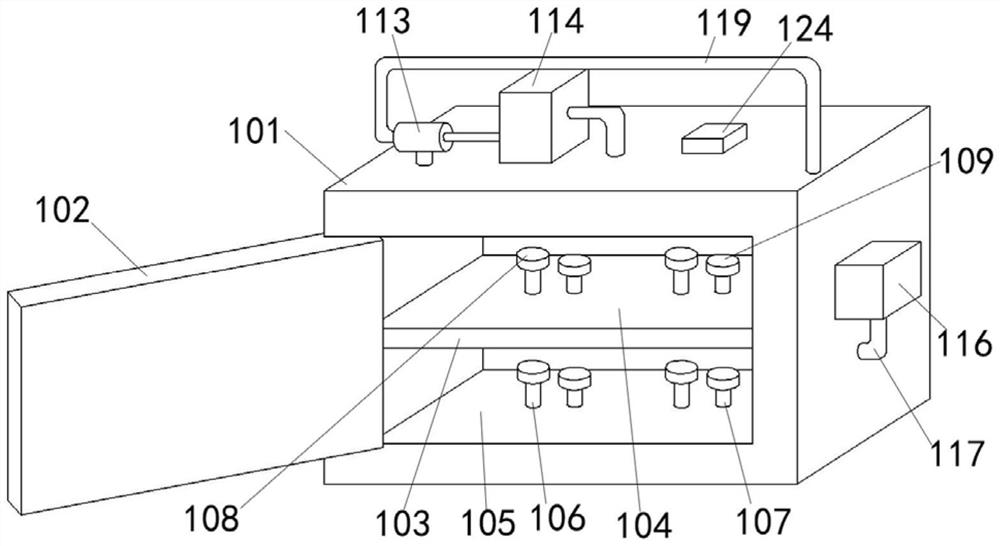

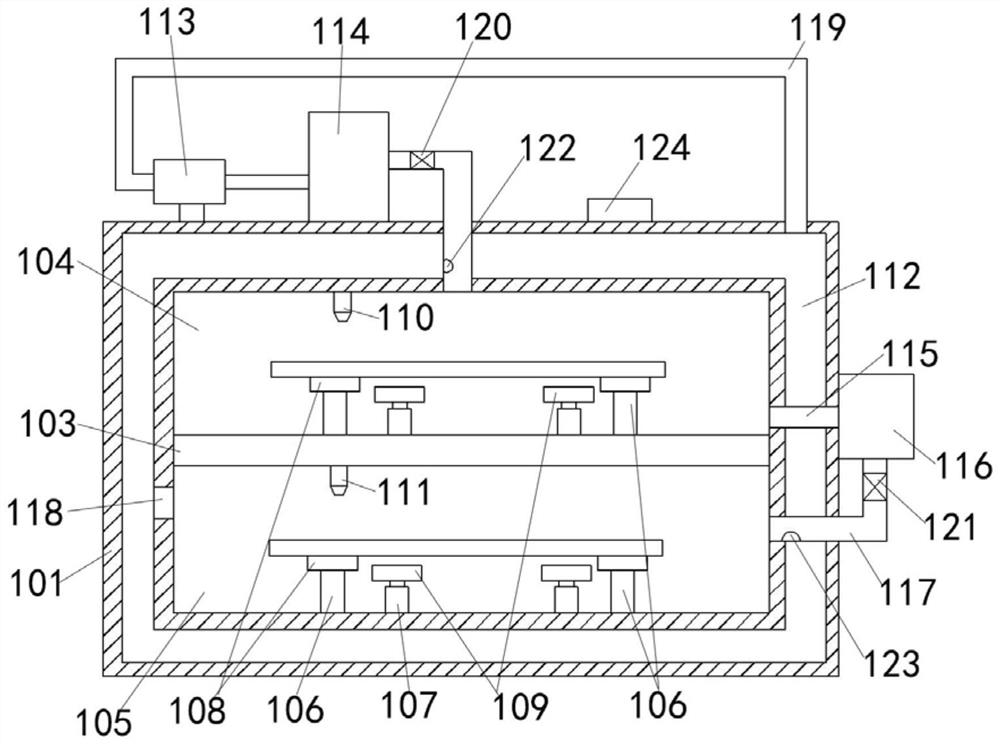

[0040] Example: such as Figure 1-3 A steel plate processing system shown includes a heating device 100 and a rolling device 200. After the steel plate is heated by the heating device 100, it is rolled by the rolling device 200. The heating device 100 includes a heating shell 101, and the heating shell 101 is composed of The hinged door 102 at the front end is closed, and the interior of the heating shell 101 is divided into an upper heating space 104 and a lower heating space 105 by a partition 103, and at least two fixing supports are fixed on the bottom walls of the upper heating space 104 and the lower heating space 105. Rod 106 and at least two electric telescopic rods 107, the upper end of each fixed pole 106 is affixed to the main support plate 108, and the upper end of each electric telescopic rod 107 is affixed to the auxiliary support plate 109, the inner wall of the heating shell 101, the partition plate 103 The lower end is respectively fixed with a first infrared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com