Crimped pipe press-fitting unit suitable for overhead contact system dropper machining

A technology of crimping tube and catenary, applied in the field of catenary hanging string processing, can solve the problems of not being able to fully guarantee the rapid development of high-speed railways, affecting the application cost of catenary hanging strings, and low production efficiency of catenary strings, and reducing labor costs. The effect of labor volume, reduction of labor intensity and labor cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

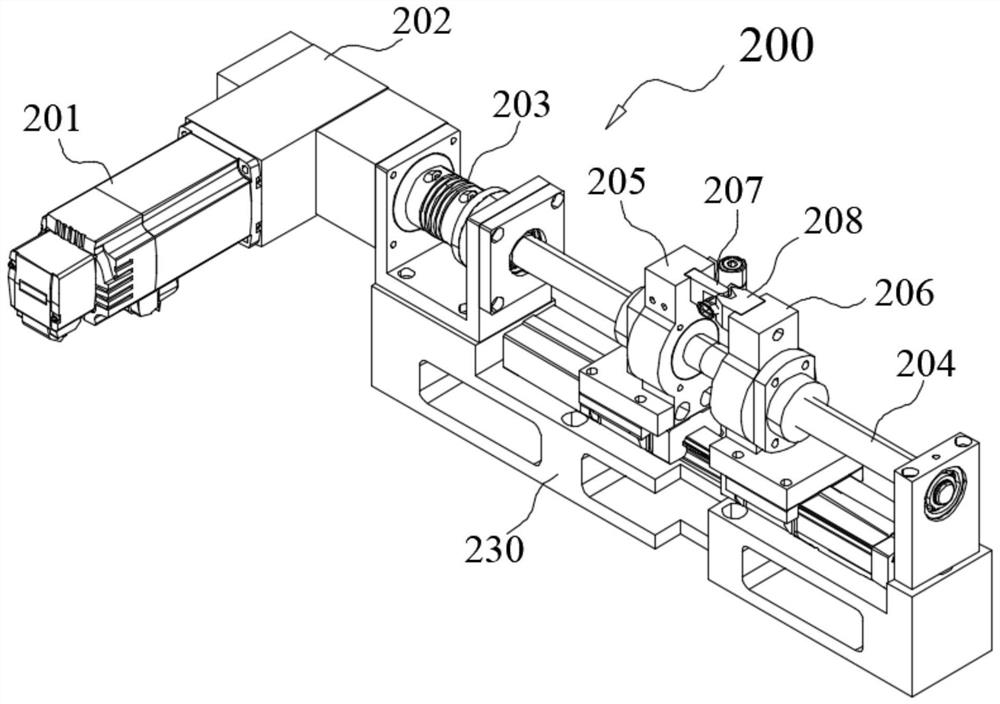

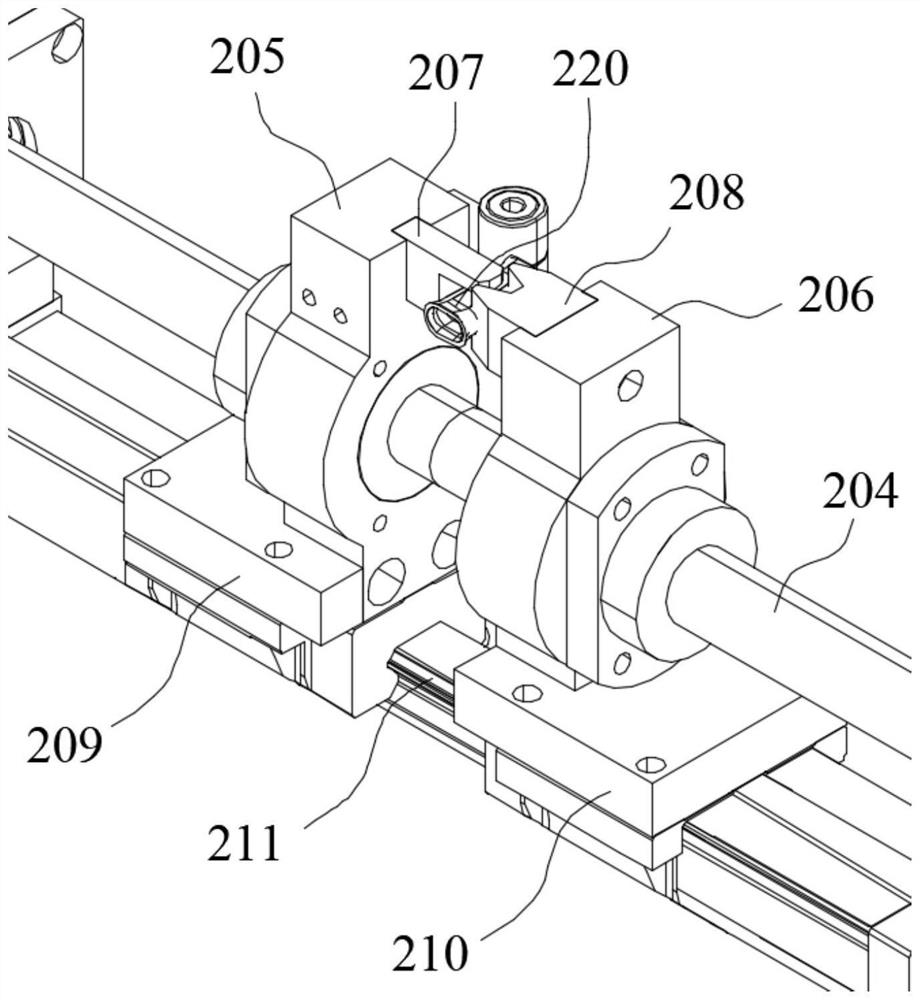

[0034] see figure 1 , 2 , in the preferred embodiment of the present invention, the crimping tube pressing unit 200 suitable for catenary hanging string processing is arranged on the bracket 230, and is mainly used for pressing after the crimping tube 220 is matched with the stranded wire. The whole process can be simplified as: twisting One end of the wire passes through the crimping tube 220 and is wound around the outer circumference of the heart-shaped ring, and then the twisted wire end turns to 180° and then passes through the crimping tube 220 (that is, there are two twisted wires that are arranged side by side in the crimping tube 220 at this moment, and A ring structure is formed on one side of the crimping tube 220 ); finally, the crimping tube 220 is pressed together, and the two stranded wires are fixed in the crimping tube 220 .

[0035] Specifically, the crimping tube pressing unit in the preferred embodiment includes a servo motor 201, a reducer 202, and a shaf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap