Production technology of big truck hub brake spring B

A production process and brake spring technology, which is applied in the production process field of large truck wheel brake spring B, can solve the problems of harsh working environment and the inability of large truck wheel brake spring B to meet the performance requirements, so as to improve the corrosion resistance and improve the service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

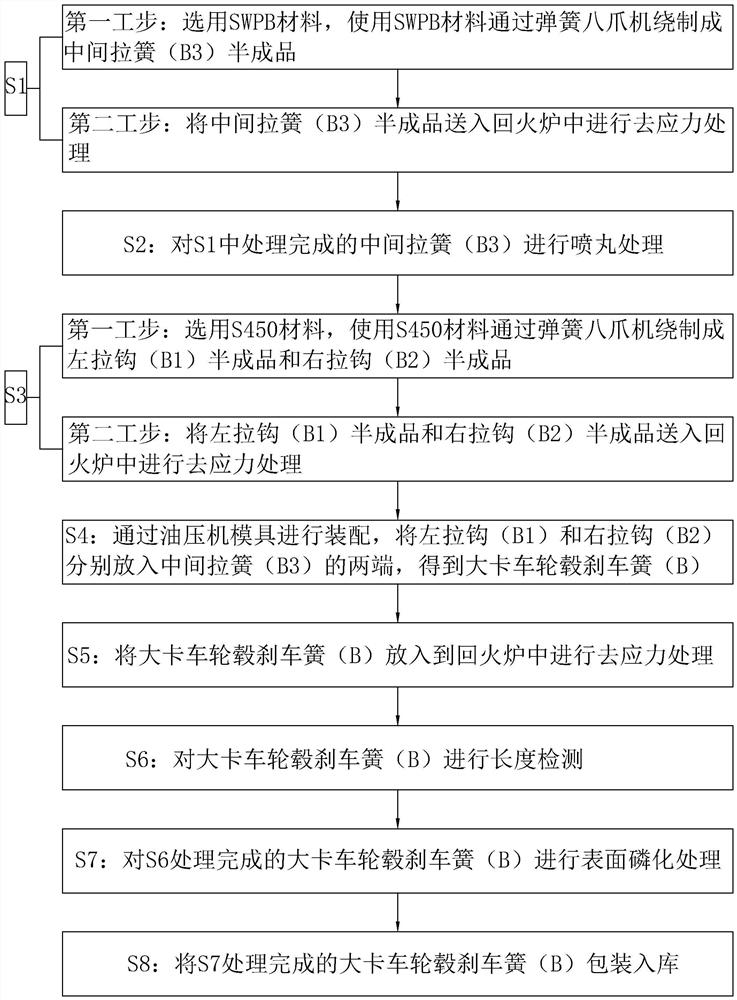

[0030] Embodiment: a kind of production technology of big truck hub brake spring B, as figure 2 shown, including the following steps:

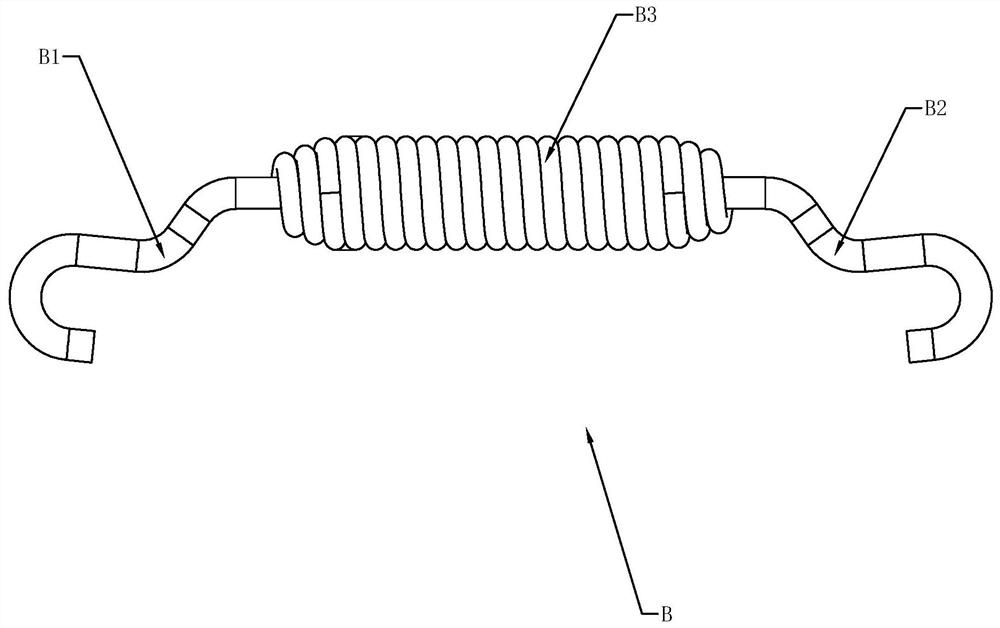

[0031] S1: The first working step: select SWPB material, SWPB is a piano steel wire, according to the designed structure, after computer programming, the SWPB material is wound into a semi-finished intermediate tension spring B3 through a spring eight-claw machine, and the shape of the intermediate tension spring B3 is as follows figure 1 shown.

[0032] The second working step: send the middle tension spring B3 which has been processed in the first working step into the tempering furnace, and carry out stress relief treatment for 30 minutes under the temperature condition of 300°C.

[0033] S2: Shot blasting the intermediate extension spring B3 processed in S1;

[0034] S3: The first working step: select S450 material, according to the designed structure, through computer programming, wind S450 material through a spring eight-jaw machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com