Novel cold heading device for automobile bolt machining

A cold heading, a new type of technology, applied in metal processing equipment, bolts, manufacturing tools, etc., can solve the problems of lens surface turbidity, low image definition, poor grasp of processing shape, etc., to improve the accuracy of judgment, easy replacement, The effect of shooting a clear picture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

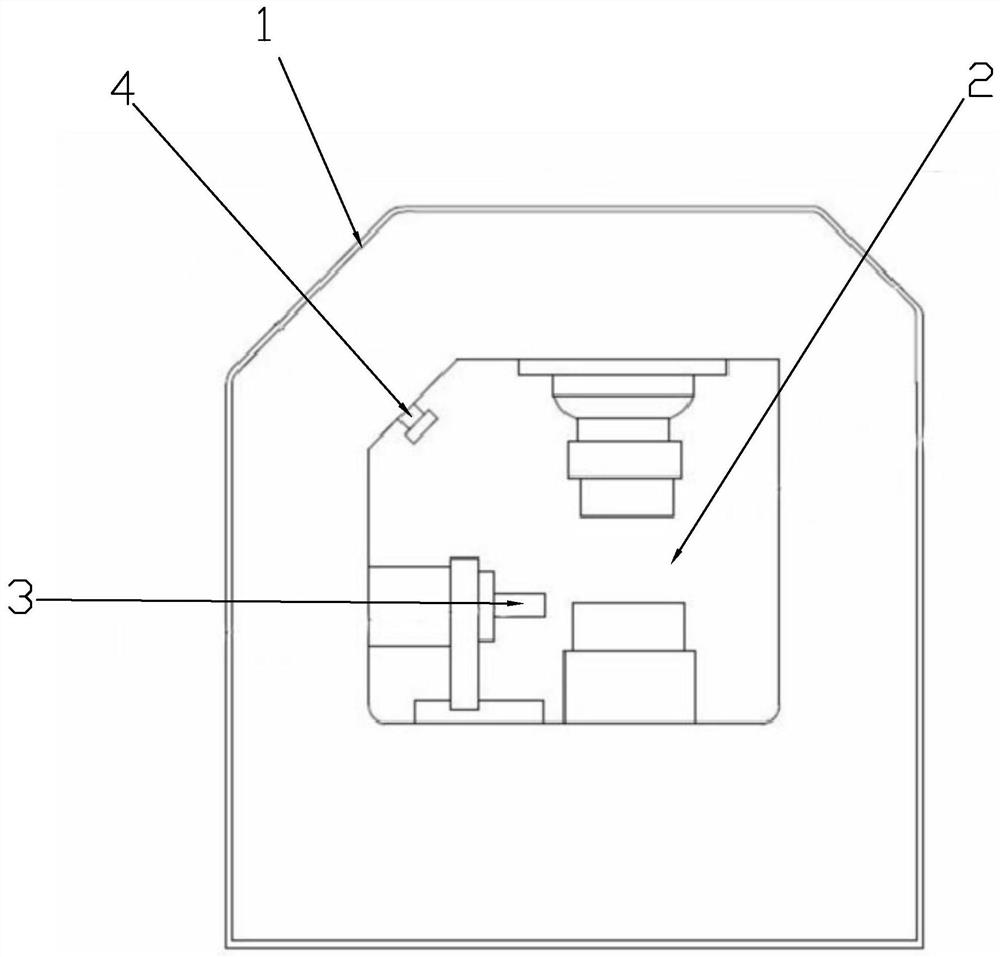

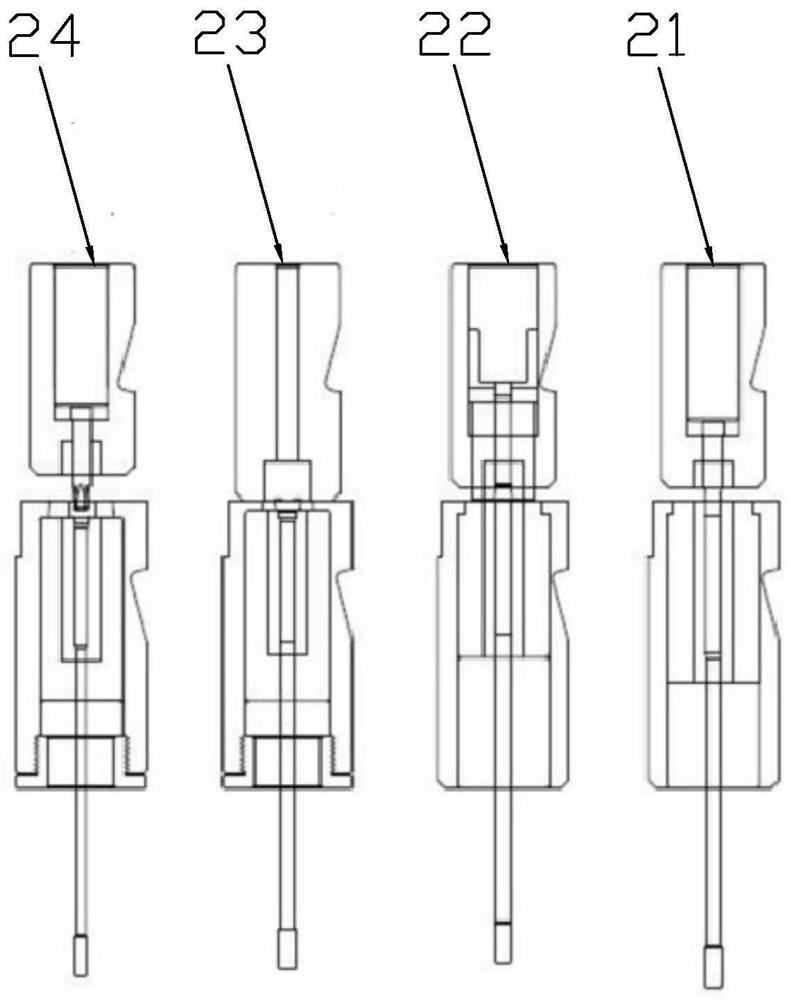

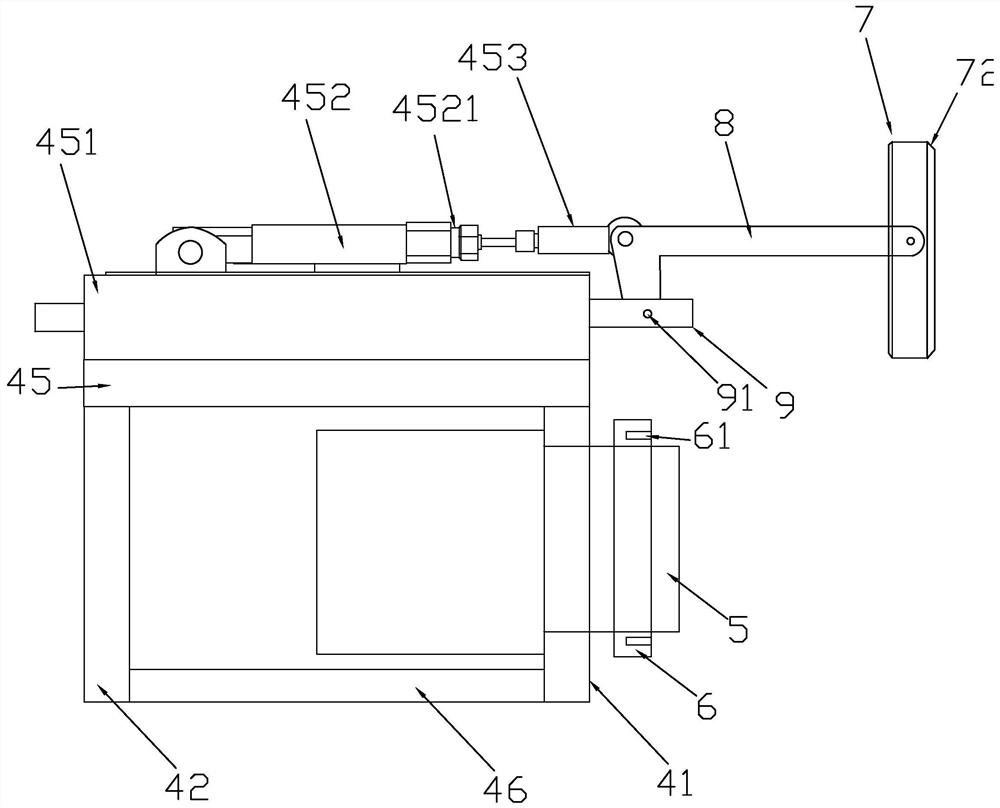

[0026] see Figure 1-Figure 5 Shown: a new type of cold heading equipment for automobile bolt processing, including a body 1, a cold heading die 2 and a manipulator 3 are arranged in the body, the manipulator 3 cooperates with the cold heading die 2 to reproduce the workpiece, and the cold heading die 2 includes sequentially set The shaping station 21, the head preforming station 22, the beam rod station 23 and the forming station 24, the body 1 is also provided with a monitoring camera 4, and the monitoring camera 4 is provided with a protective cover shell, and the protective cover The housing is formed by sealing the front end plate 41, the rear end plate 42, the left side plate, the right side plate, the top plate 45 and the bottom plate 46. There is a lens hole on the front plate, and a lens 5 is connected in the lens hole, and the front end of the lens 5 covers A bracket 6 is provided, and an LED lamp 61 is arranged on the bracket 6. A rotating cylinder 451 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com