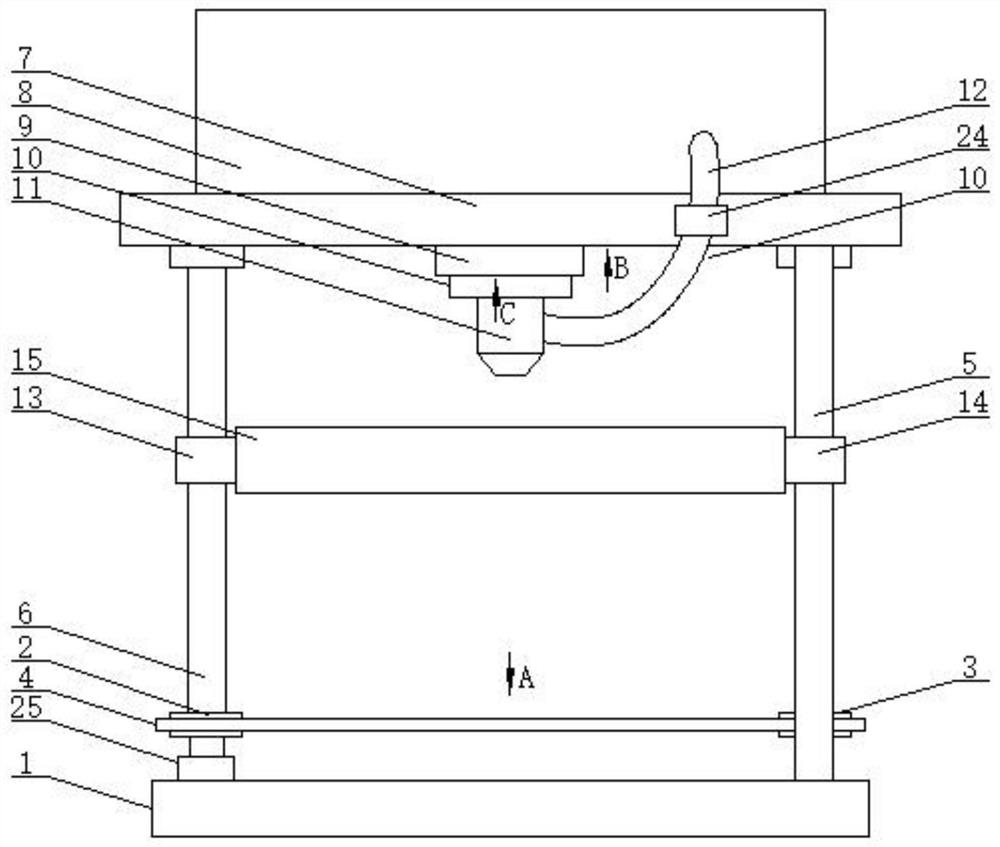

Tic steel hard alloy 3D printing and molding device

A cemented carbide, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of large space occupation, low printing accuracy, high energy consumption, and achieve the effect of convenient operation, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

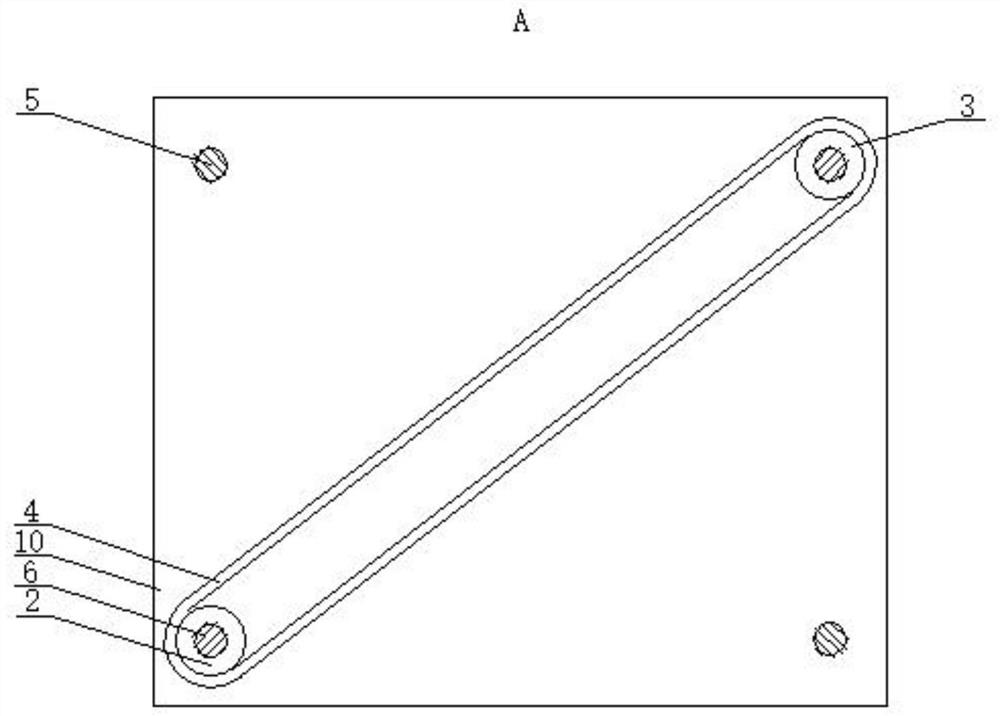

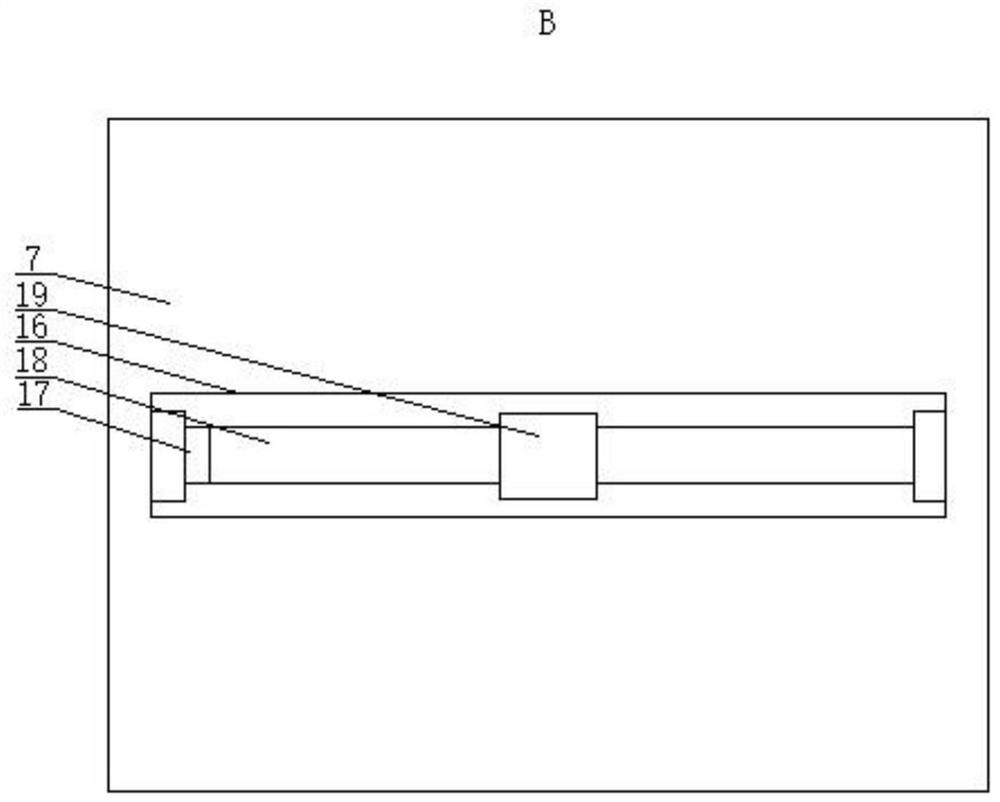

[0026] When using this device, the Tic steel hard alloy powder is first placed in the storage box 8, and then the object structure to be printed is input to the control device through the scanning device, and then the control device simultaneously controls the first motor 25 and the second motor 17 works with the third motor 21, and the first motor 25 works through the cooperative transmission of the first sprocket 2, the second sprocket 3 and the chain 4, driving the horizontal plate 15 to move downward gradually, the second motor 17 and the third motor 21 Control the trajectory of the nozzle 11 on the X-axis and Y-axis respectively. With the movement of the nozzle 11, the Tic steel cemented carbide powder is ejected from the storage box 8, and the printing is performed layer by layer until the printing is completed; the structure of the present invention is simple, Easy to operate, small size, powered by the first motor, combined with the transmission of the first sprocket, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com