Pipe cutting device for machining

A pipe cutting and machining technology, applied in metal processing equipment, shearing machine equipment, pipe cutting devices, etc., can solve the problems of increased human labor, low cutting efficiency, etc., and achieves a high degree of automation, high cutting efficiency, and continuous cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

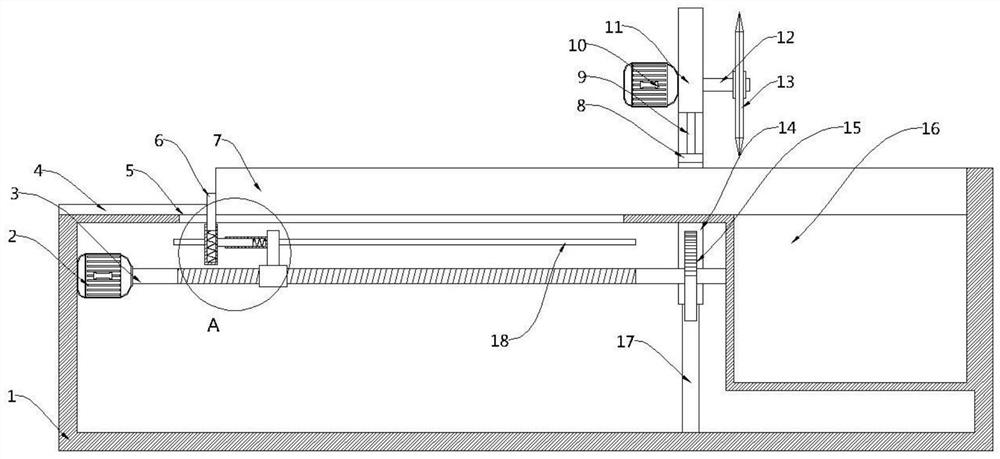

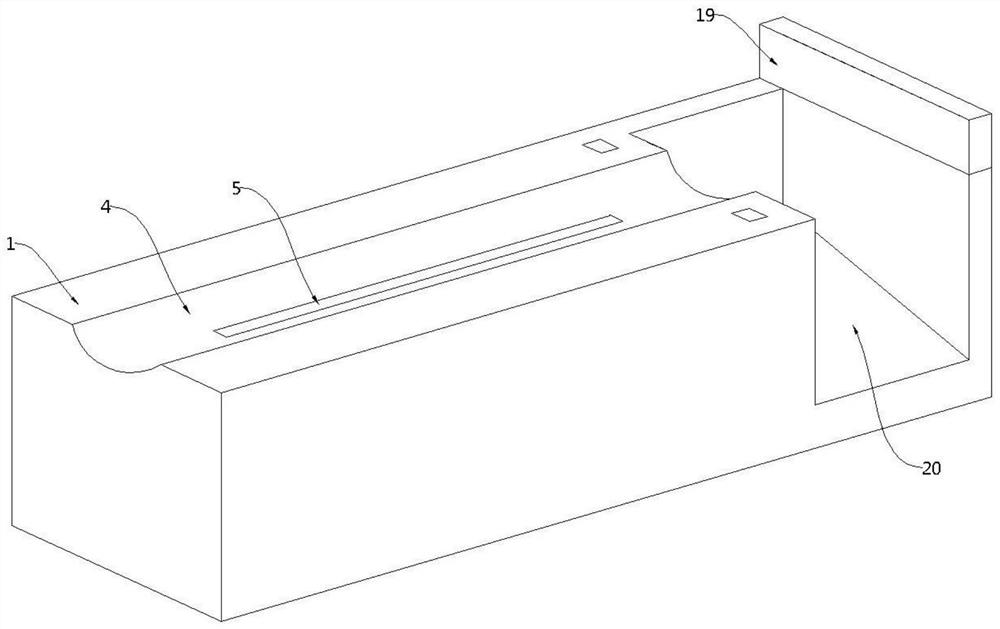

[0025] see Figure 1-4 , this embodiment provides a pipe cutting equipment for mechanical processing, including a bottom box 1, a cutting assembly arranged on the upper part of the bottom box 1, a pusher assembly 6 arranged on one side of the cutting assembly, and a Inside the bottom box 1 is a driving assembly for driving the pusher assembly 6 to move towards the cutting assembly. A baffle 19 is fixedly arranged on the side of the cutting assembly away from the pusher assembly 6. Specifically, the cutting assembly includes Movable plate 11, the second motor 10 that is fixedly arranged on the movable plate 11 towards the pusher assembly 6 side and the cutting wheel 13 that is arranged on the movable plate 11 away from the pusher assembly 6 side, the output end of the second motor 10 is fixedly connected The rotating shaft 12, the end of the rotating shaft 12 away from the second motor 10 passes through the movable plate 11 and is fixedly connected with the cutting wheel 13, th...

Embodiment 2

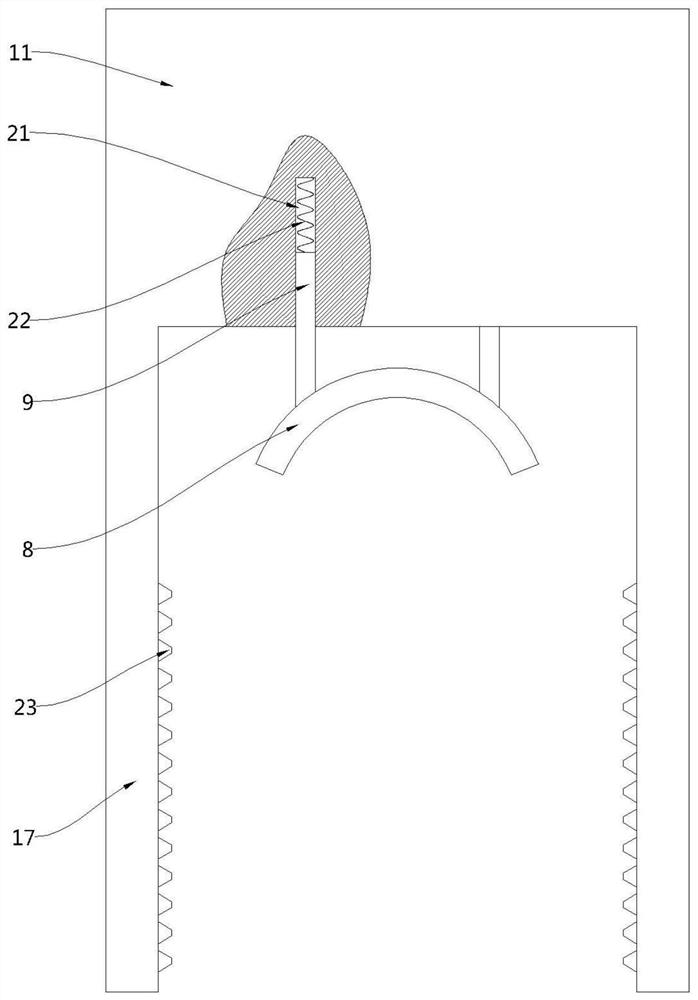

[0038] see figure 1 and image 3 , a pipe cutting device for mechanical processing. Compared with Embodiment 1, this embodiment is provided with a pressing plate 8 under the movable plate 11, a connecting rod 9 is fixedly installed on the upper part of the movable plate 8, and a connecting rod 9 is fixed at the bottom of the movable plate 11 There is a concave hole 21 , the upper end of the connecting rod 9 extends to the inside of the concave hole 21 and is fixedly connected with a first elastic body 22 , and the end of the first elastic body 22 away from the connecting rod 9 is fixedly connected with the bottom of the concave hole 21 .

[0039] When the driving half gear 15 drives the movable plate 11 to move downward through the drive rod 14, the movable plate 11 drives the pressure plate 8 to move downward, thereby using the pressure plate 8 to compress the pipeline 7 to prevent the pipeline 7 from being caused by the rotational force generated during cutting. Rocking occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com