Self-adaptive aligning and clamping device suitable for butt welding processing of tubular parts

A clamping device and self-adaptive technology, applied in the field of mechanical processing, can solve the problems of difficult shape and position tolerance, low dimensional tolerance accuracy, and high-precision position tolerance, so as to improve the position tolerance accuracy and accurate positioning after welding , the effect of eliminating the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments and the accompanying drawings. as a limitation of the present invention.

[0056] As shown in this application and the claims, unless the context clearly dictates otherwise, the words "a," "an," "an," and / or "the" are not intended to specifically refer to the singular and include the plural.

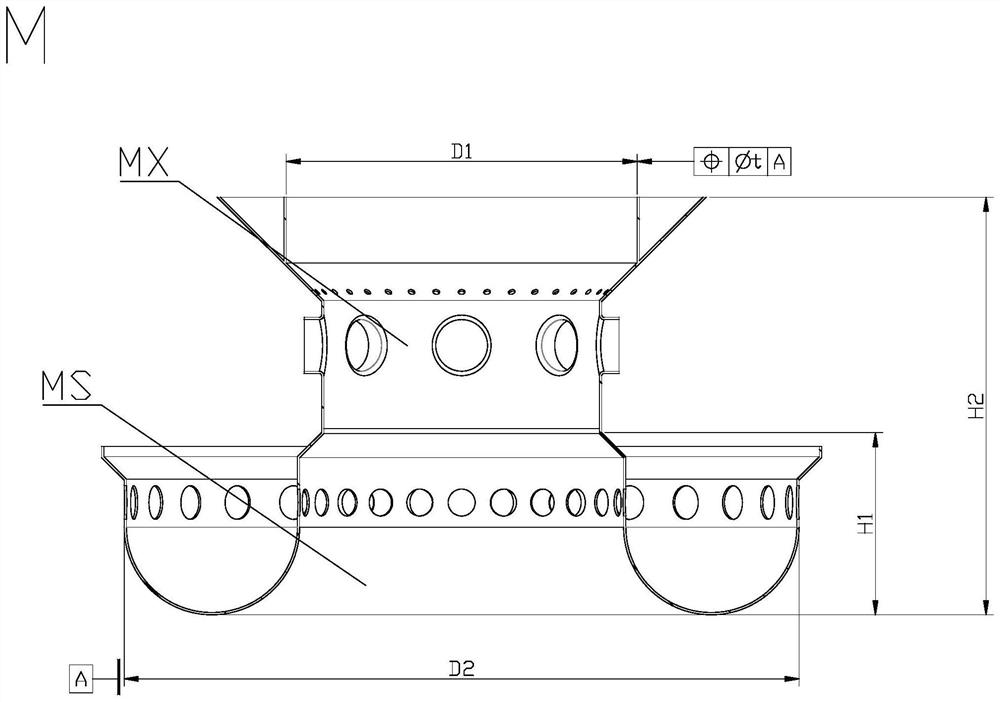

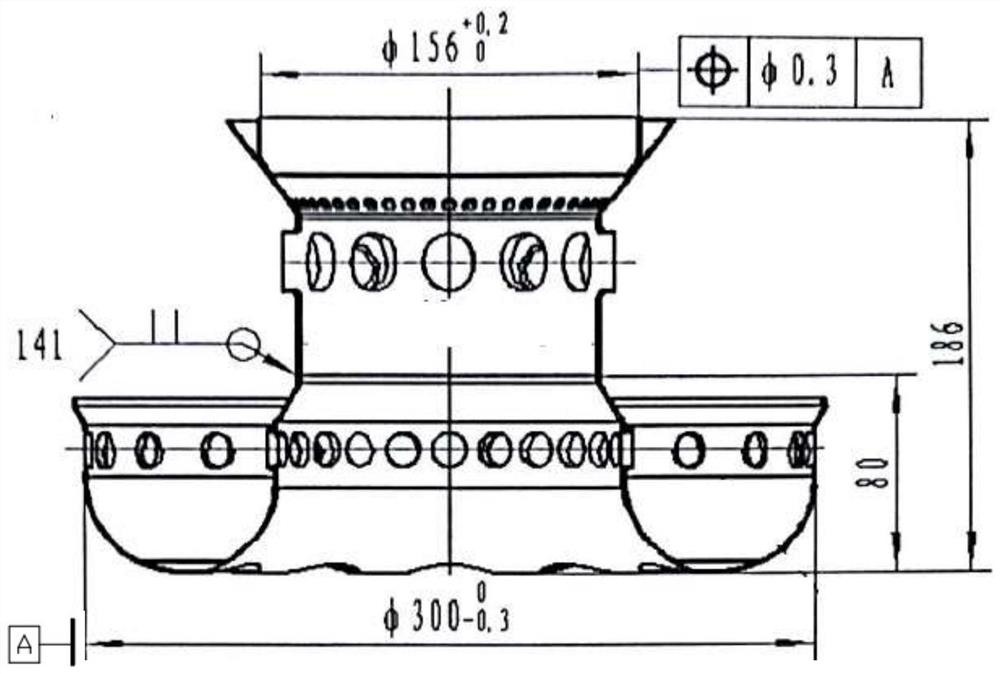

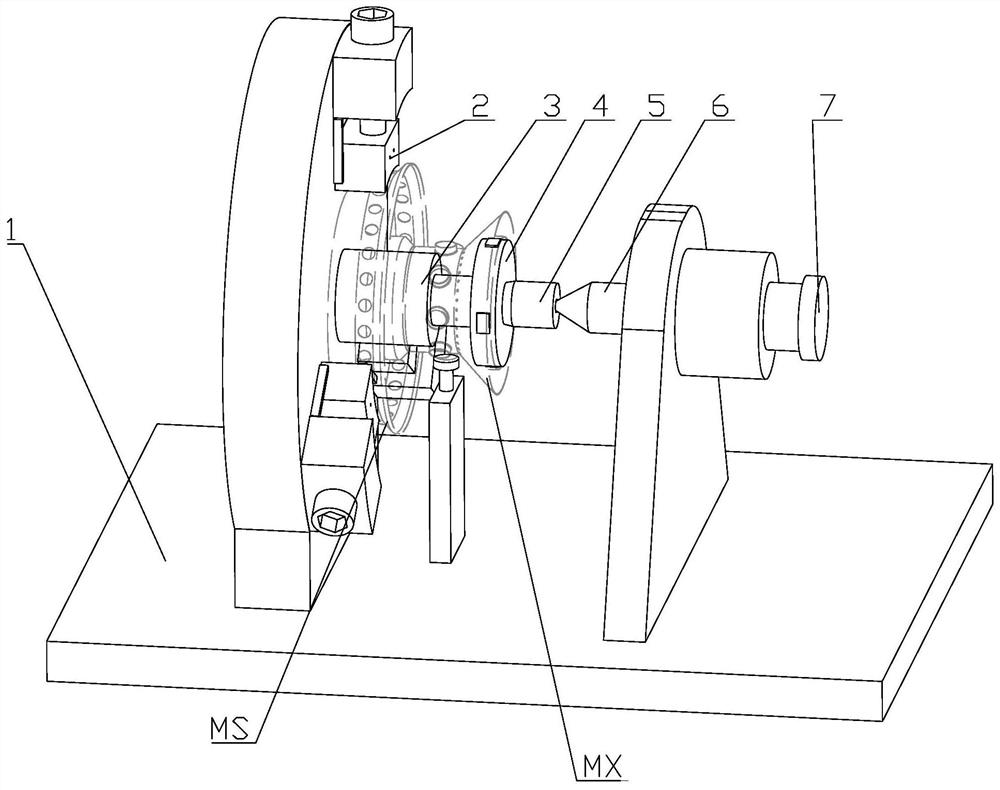

[0057] In some embodiments, a self-adaptive alignment clamping device suitable for butt welding processing of tubular parts is used for the welding of tubular parts M. Tube parts M such as figure 1 Shown are thin-walled tubular parts, including upper tubular part MX and lower tubular part MS, both upper tubular part MX and lower tubular part MS are thin-walled tubular parts, which require butt welding The positional accuracy is high, that is, the axis of the upper tube part MX and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com