A patch equipment and process for attaching polarizers to glass workpieces

A polarizer and workpiece technology, which is applied in the field of glass workpiece processing equipment, can solve problems such as difficulty in achieving unified control, poor equipment collaboration performance, and difficulty in meeting production requirements, so as to meet production requirements, facilitate overall control, and occupy a small space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

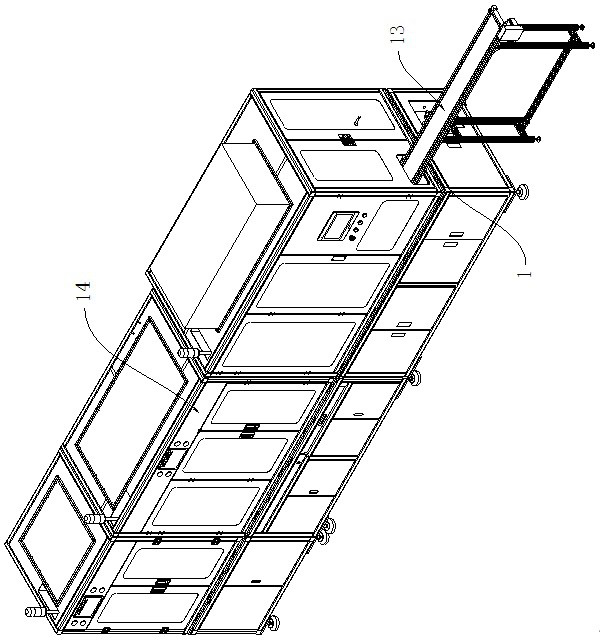

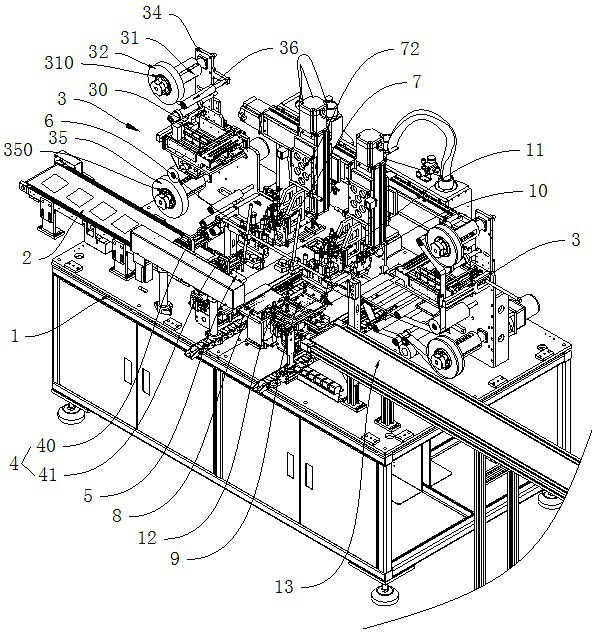

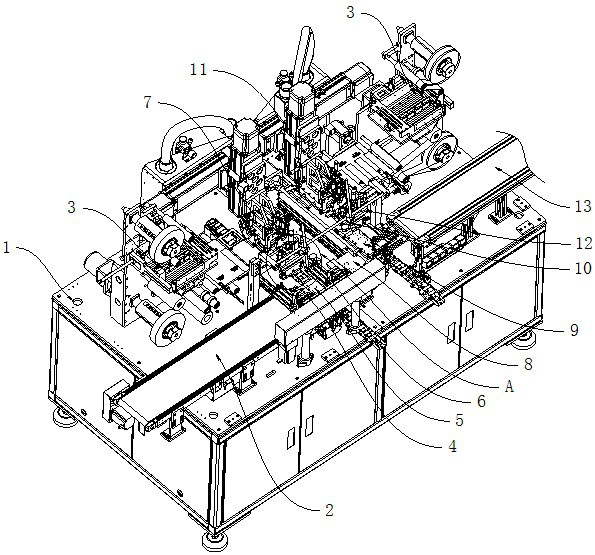

[0018] This embodiment relates to a patch device for attaching polarizers to glass workpieces, combined with Figure 1 to Figure 3 As shown, it includes a frame 1, and the frame 1 is provided with a feeding and conveying mechanism 2, a polarizer feeding mechanism 3, a picking and unloading mechanism 4, a left patch platform mechanism 5, and a left cleaning mechanism. Mechanism 6, a left sticking mechanism 7, a flipping platform mechanism 8, a right patching platform mechanism 9, a right cleaning mechanism 10, a right sticking mechanism 11, a feeding manipulator 12 and a discharging conveying mechanism 13, among which :

[0019] The feeding conveying mechanism 2 is used for conveying glass workpieces;

[0020] The polarizer feeding mechanism 3 is arranged adjacent to the feeding and conveying mechanism 2, and the polarizer feeding mechanism 3 is used for feeding polarizers to the left head sticking mechanism 7 and the right sticking mechanism 11;

[0021] The picking and unlo...

Embodiment 2

[0053] In practical applications, a robot or a suction nozzle is generally used to pick up the polarizer, and then the picked polarizer is placed in the preset patch actuator, but the process of picking and placing the polarizer is slow, resulting in the overall action of the patch equipment. The efficiency is low, and it is easy to pick up two or more pieces, resulting in low accuracy and reliability of the step of picking and placing polarizers, and it is difficult to meet production requirements.

[0054] In this regard, this embodiment proposes a polarizer double-piece detection and conveying mechanism that can improve the efficiency of polarizer taking and feeding, and can ensure single-piece transportation at the same time. figure 2 and Figure 4 As shown, it includes a polarizer feeding mechanism 3, the polarizer feeding mechanism 3 includes a material box 30, a tape conveying device 31, a tape recycling device 35 and a fiber optic sensor 33, the tape conveying device ...

Embodiment 3

[0062] In practical applications, in order to improve the quality of the patch, before the polarizer is attached to the glass workpiece, a cleaning step is generally performed, such as blowing, wiping, etc., in order to remove the dust on the surface of the glass workpiece, but the existing cleaning methods cannot be used. To ensure sufficient cleanliness of the glass workpiece, the quality of the glass product after the patch is poor, and the product yield is low.

[0063] In this regard, this embodiment proposes a glass workpiece cleaning mechanism with high cleanliness, good action continuity, and improved processing quality. figure 2 , image 3 , Figure 5 and Image 6 As shown, the cleaning mechanism includes an alcohol spray assembly 60 and a scraper assembly 61, the alcohol spray assembly 60 is located on the front side of the scraper assembly 61, and the alcohol spray assembly 60 and the scraper assembly 61 are provided below the A patch platform mechanism for glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com