Mechanical tool for welding outer wall of spiral aluminum tube

A technology for welding machinery and aluminum tubes, applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effects of good rigidity, high matching performance, and strong collaboration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings.

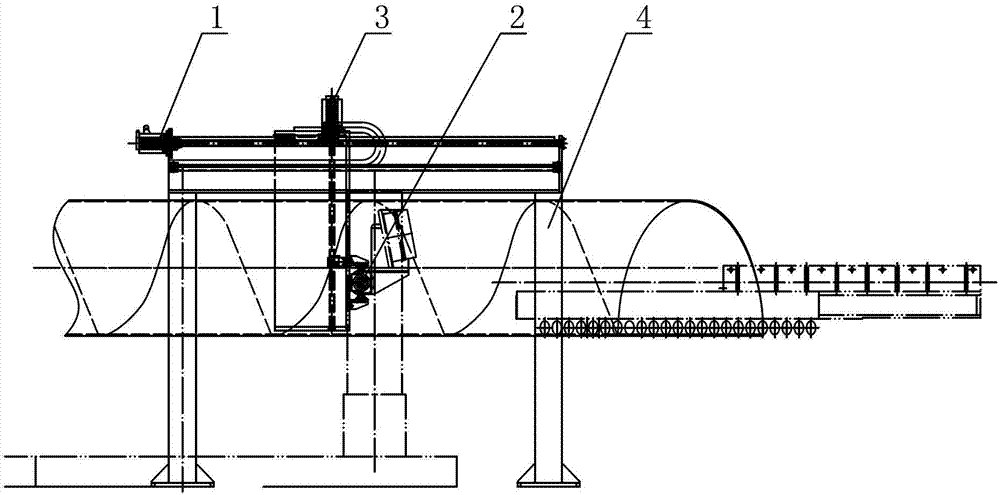

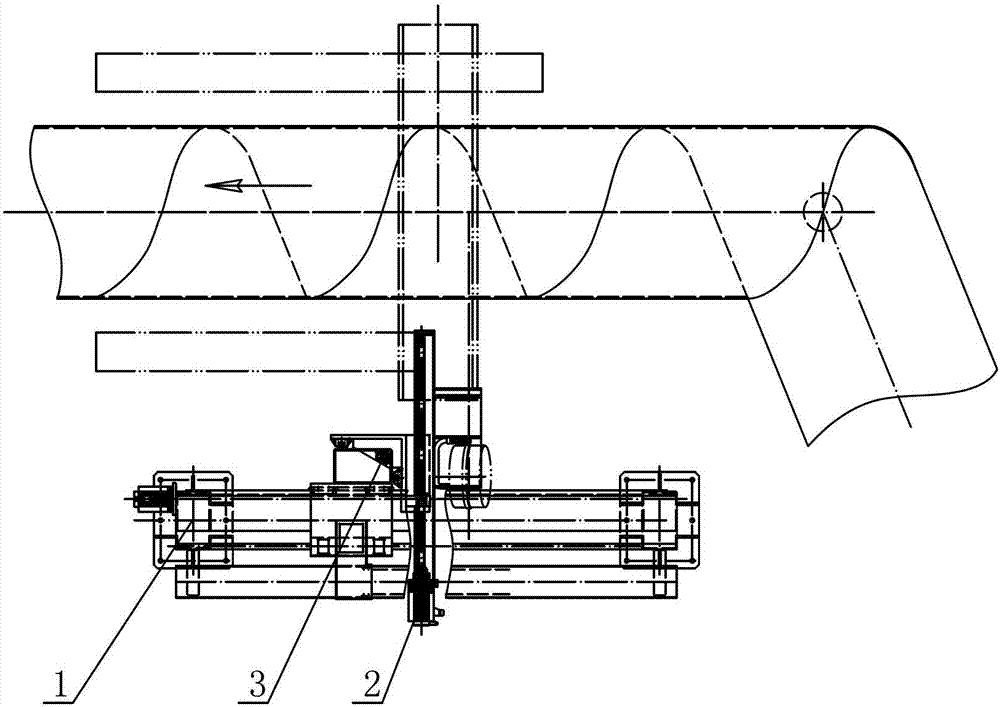

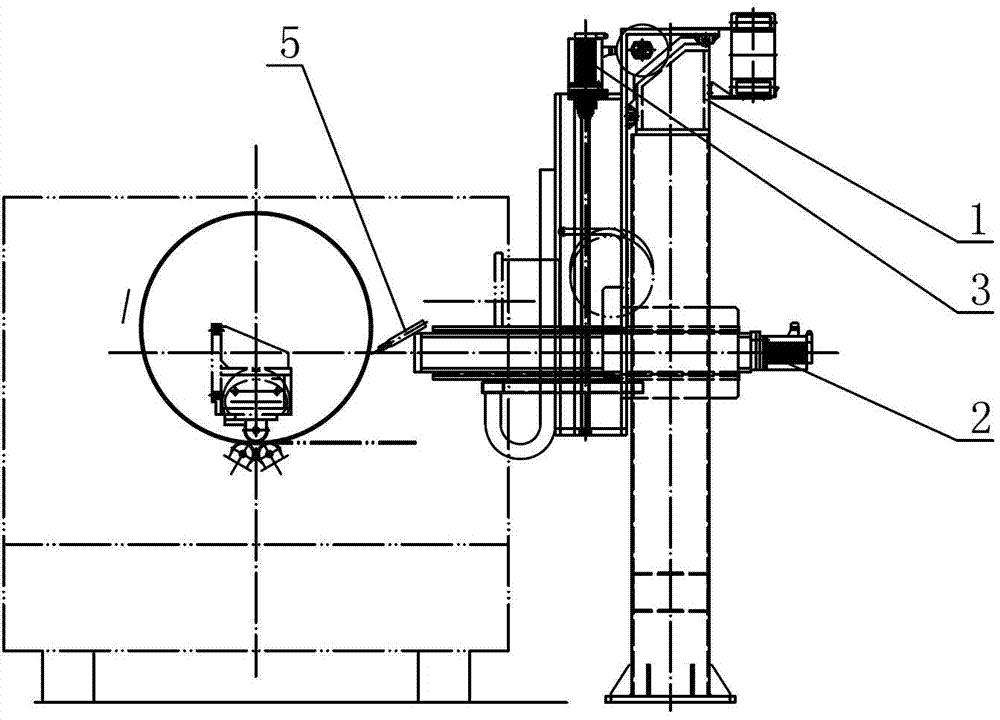

[0022] like Figure 1 to Figure 12 Shown: The mechanical tooling for welding the outer wall of the spiral aluminum tube includes X-axis traveling mechanism 1, Y-axis traveling mechanism 2, Z-axis traveling mechanism 3, gantry frame 4, welding torch 5, X-axis motor X1, X-axis ball screw X2, walking body X4, X-axis guide rail X5, sliding seat connecting plate Y1, sliding seat Y2, Y-axis guide rail Y3, Y-axis motor Y4, Y-axis ball screw Y5, Z-axis motor Z1, Z-axis ball screw Z2, lifting body Z3, Z-axis guide rail Z4, etc.

[0023] like Figure 1 ~ Figure 3 As shown, the present invention includes a gantry 4 installed above the outer wall welding machine, and an X-axis traveling mechanism 1, a Y-axis traveling mechanism 2 and a Z-axis traveling mechanism 3 are installed on the gantry 4;

[0024] like Figure 4 ~ Figure 6 As shown, the X-axis traveling mechanism 1 includes an X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com