Electrode stem lifting device of electroslag furnace

A technology of lifting device and electrode rod, which is applied in the field of electroslag furnace, can solve problems such as the decline of steel ingot quality and difficult temperature control, and achieve the effects of prolonging service life, high working efficiency and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

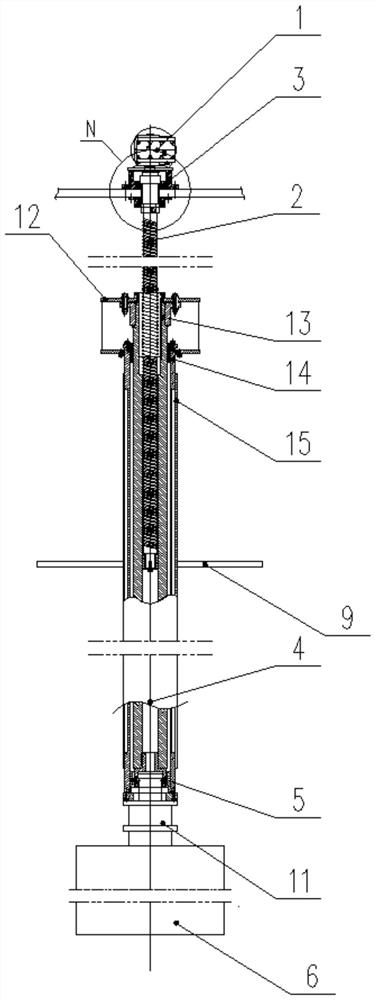

[0024] An electroslag furnace electrode rod lifting device, including a driving motor 1, is characterized in that the driving motor 1 is connected with a lead screw 2 arranged in the vertical direction, the top of the lead screw 2 is sleeved with a bearing support 3, and the screw The bottom end of the lever screw 2 is connected with an electrode rod 4, and a thrust bearing is connected between the bearing support 3 and the lead screw 2. The electrode rod 4 includes an inner ring rod 13, a middle ring rod 14 and an outer ring rod 15 from the inside to the outside. , The bottom end of the electrode rod 4 is connected with a pneumatic chuck 5, the pneumatic chuck 5 is installed between the inner ring rod 13 and the outer ring rod 15, and the pneumatic chuck 5 is connected with the consumable electrode 6.

[0025] The production structure adopts a single self-consumable electrode 6 up and down. On the one hand, the step of switching electrodes is omitted. The whole production proc...

Embodiment 2

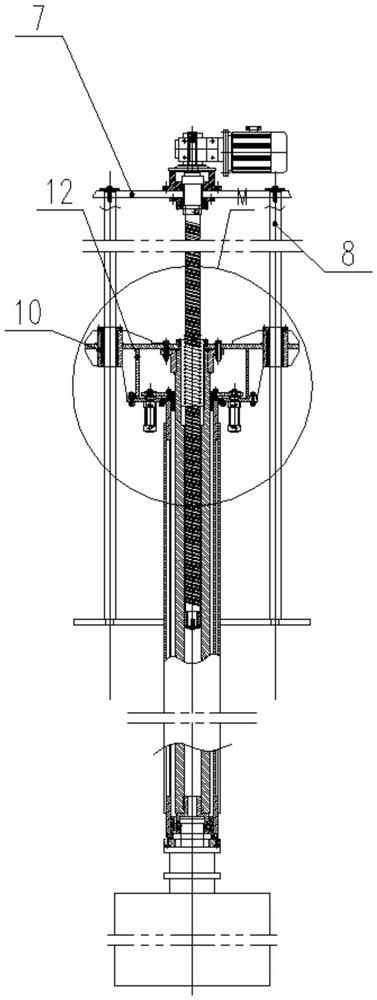

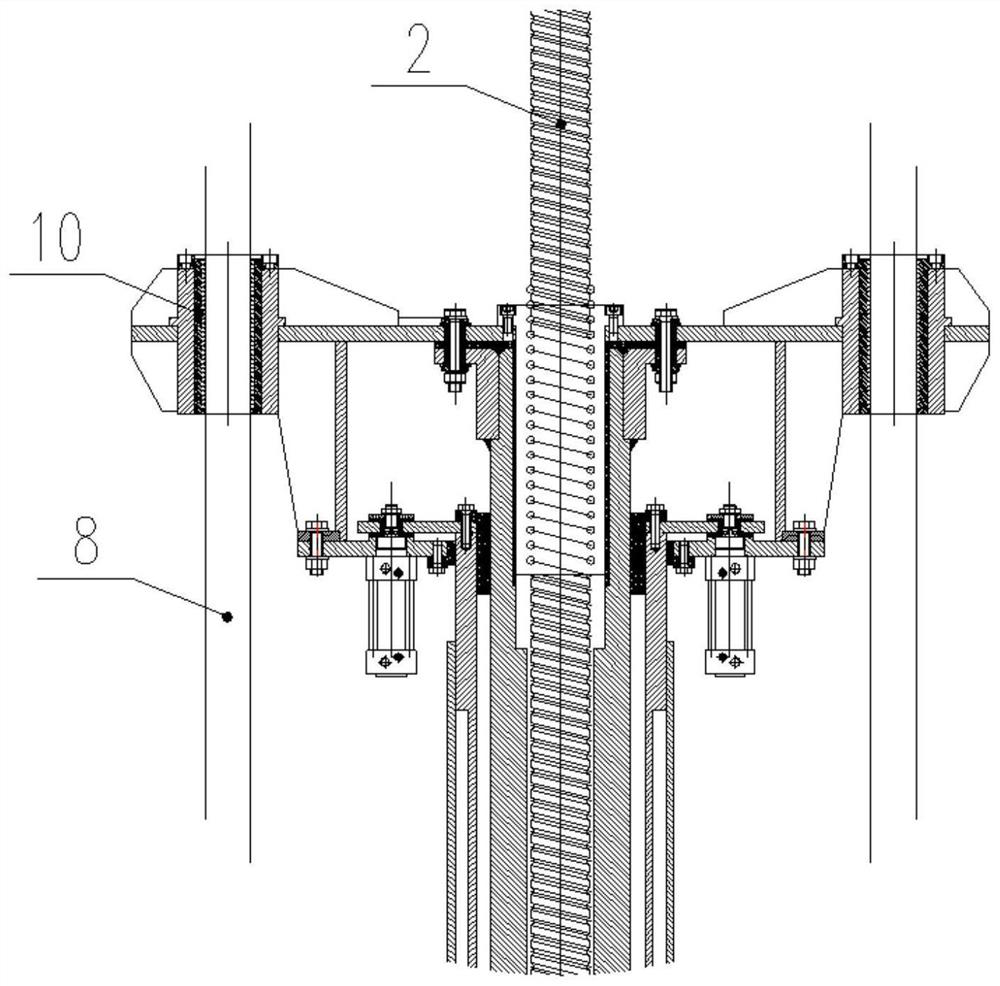

[0027] On the basis of Embodiment 1, both sides of the bearing support 3 are connected with an upper horizontal strut 7, and the upper horizontal strut 7 is connected with a guide rod 8 arranged parallel to the lead screw 2, and the bottom end of the guide rod 8 A lower horizontal strut 9 is connected, the lower horizontal strut 9 is connected with the electrode rod 4, the upper end of the electrode rod 4 is connected with a guide sleeve 10 set on the guide rod 8, and the lower horizontal strut 9 is connected to the outer ring rod 15 , The guide sleeve 10 is connected with the inner ring rod 13 .

[0028] Preferably, a sealing washer is connected between the upper horizontal strut 7 and the bearing support 3 .

[0029] Through the two symmetrical guide rods 8 and the guide sleeve 10 matched with the guide rods 8, it is ensured that the consumable electrode 6 moves up and down stably along the set direction during the lifting process, which facilitates the precise docking with ...

Embodiment 3

[0031] On the basis of Embodiment 1, a conductive electrode 11 is connected between the consumable electrode 6 and the pneumatic chuck 5, the upper end of the conductive electrode 11 is installed in the pneumatic chuck 5, and the lower end of the conductive electrode 11 is connected to the consumable electrode 6. Fixed connection. The conductive electrode 11 that is only used for conduction separates the consumable electrode 6 from the pneumatic chuck 5 by a certain distance, thereby avoiding damage to the pneumatic chuck 5 due to long-term exposure to high temperature, and prolonging the service life of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com