Energy dissipation and shock absorption type bridge tower structure

A bridge tower and tower column technology is applied in the field of energy-consuming and shock-absorbing bridge tower structures, which can solve the problems of the increase in the section size of the tower bottom and the reinforcement ratio of the main reinforcement, and the uneconomical bridge tower and foundation, so as to improve the seismic capacity and safety. performance, good construction convenience, and convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

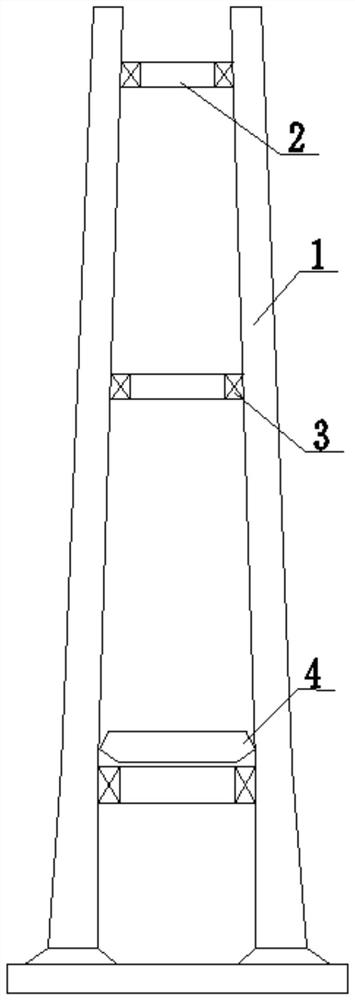

[0054] see figure 1 , 2 As shown, the embodiment of the present application provides an energy-dissipating and shock-absorbing bridge tower structure, which includes:

[0055] A pair of pylons 1;

[0056] A plurality of beams 2 arranged sequentially from top to bottom along the height direction of the tower column 1;

[0057] The two ends of the beam 2 are respectively connected to the inner side of each tower column 1 through at least one energy-dissipating and shock-absorbing component 3; wherein,

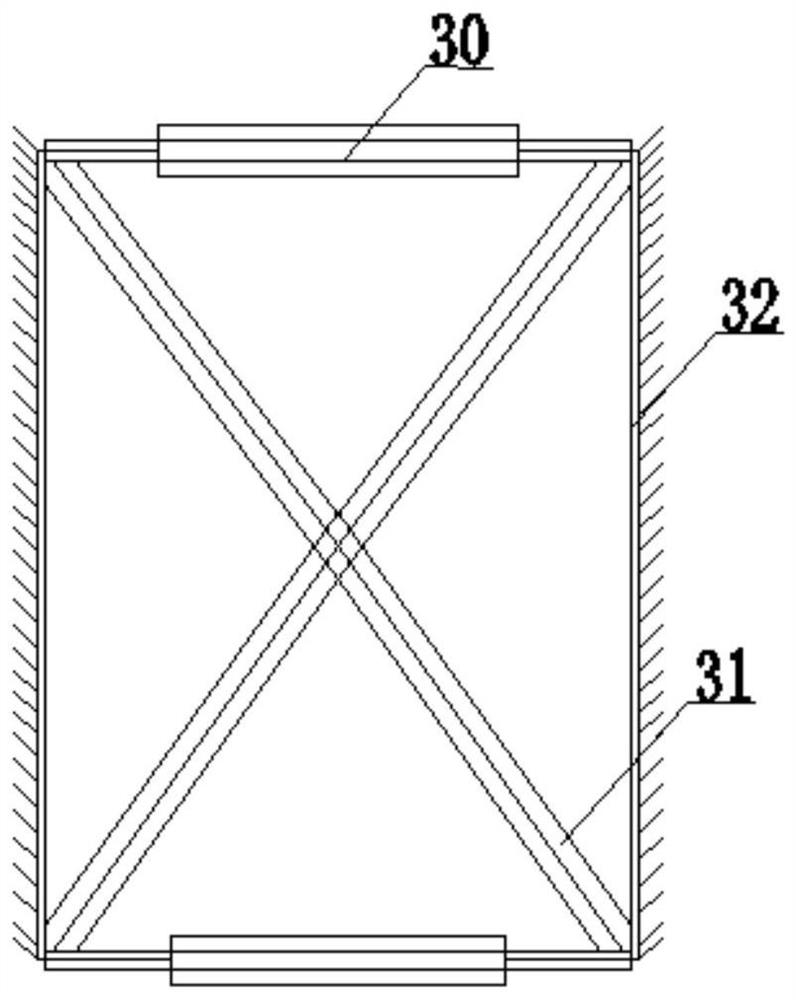

[0058] The energy-dissipating shock-absorbing component 3 includes a pair of tension-compression members 30 arranged in parallel, two support members 31 and two connection plates 32 arranged in parallel. The two tension-compression members 30 are connected with the two connection plates 32 to form a rectangular frame, two supporting members 31 are respectively connected to the opposite corners in the rectangular frame;

[0059] The connecting plate 32 is connected to the inne...

Embodiment 2

[0068] see figure 1 , 3 As shown, the embodiment of the present application provides an energy-dissipating and shock-absorbing bridge tower structure, and the system includes:

[0069] A pair of pylons 1;

[0070] A plurality of beams 2 arranged sequentially from top to bottom along the height direction of the tower column 1;

[0071] Both ends of the beam 2 are respectively connected to the inner side of each tower column 1 through at least one energy-dissipating and shock-absorbing component 3; wherein,

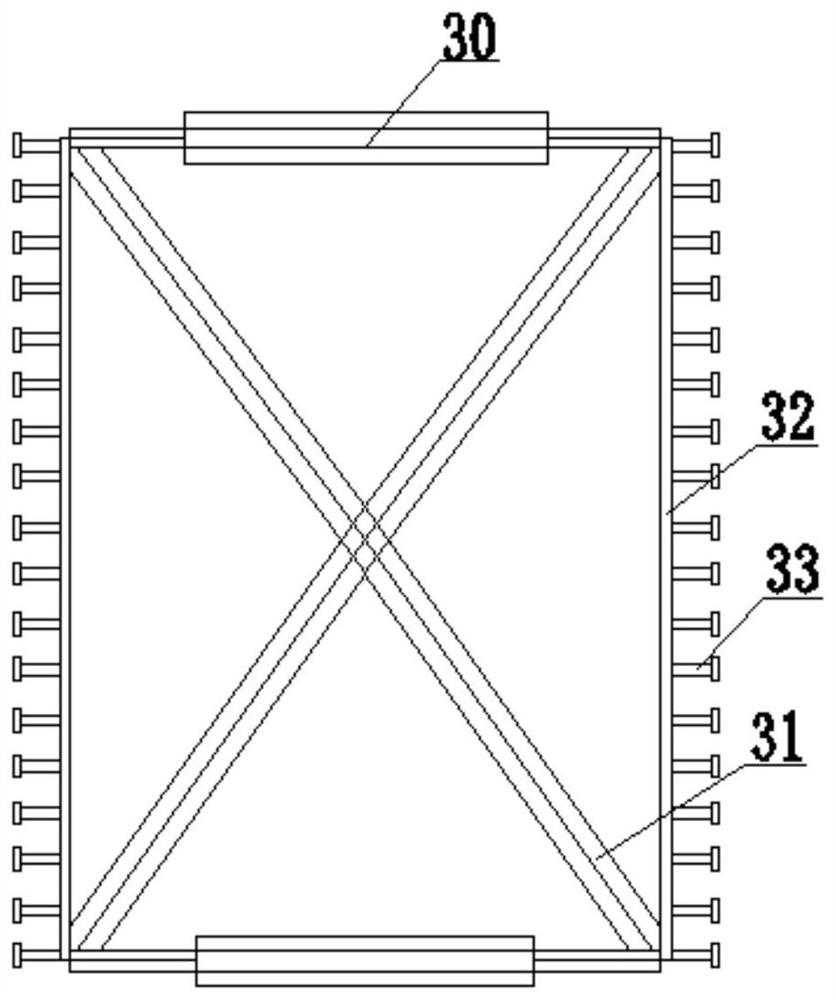

[0072] The energy-dissipating and shock-absorbing component 3 includes a pair of tension-compression members 30 arranged in parallel, two support members 31 and two connection plates 32 arranged in parallel. The two tension-compression members 30 are connected with the two connection plates 32 to form a rectangular Frame, two supporting members 31 are respectively connected to the opposite corners in the rectangular frame;

[0073] The connecting plate 32 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com