High-strength anti-loosening screw nut

An anti-loosening, high-strength technology, applied in the field of hardware parts, can solve the problems of shortening the service life of the combined nut, falling off, displacement or loosening of the fixed parts, etc., so as to improve the anti-loosening performance, improve the tightness, and ensure the stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings:

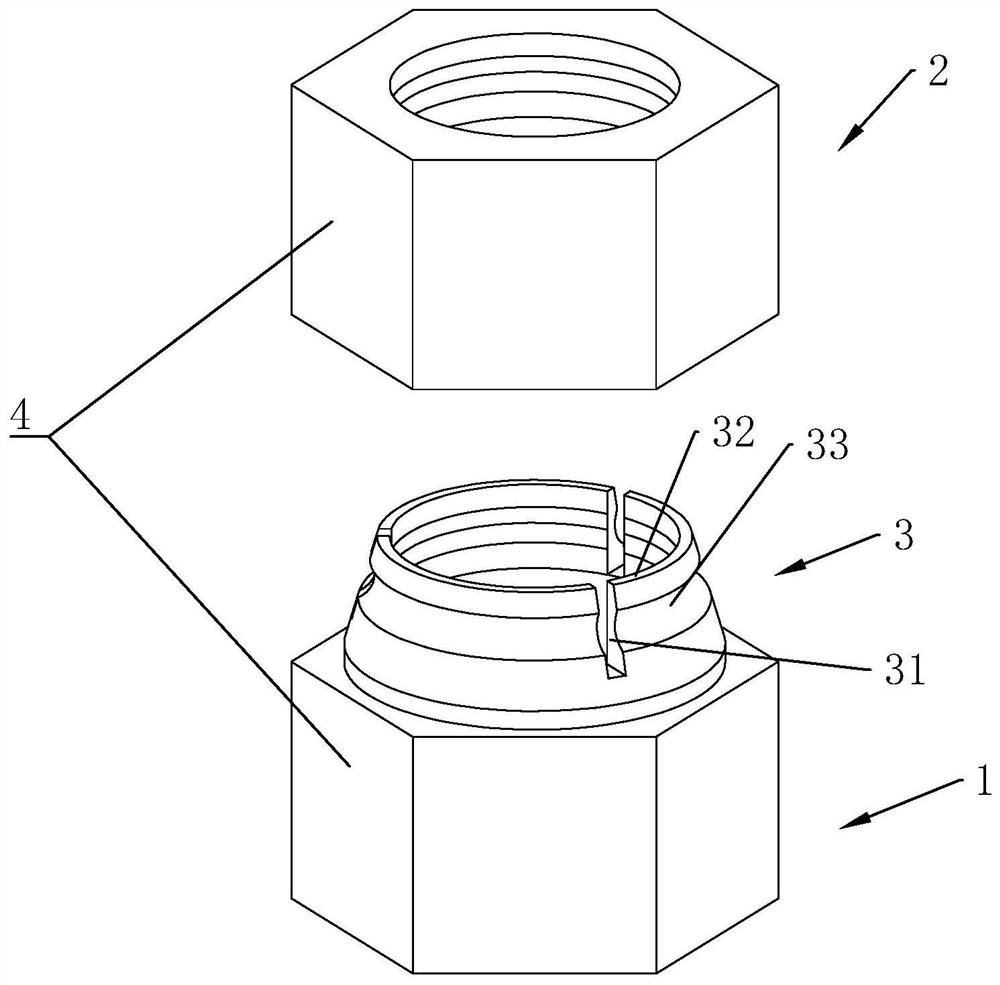

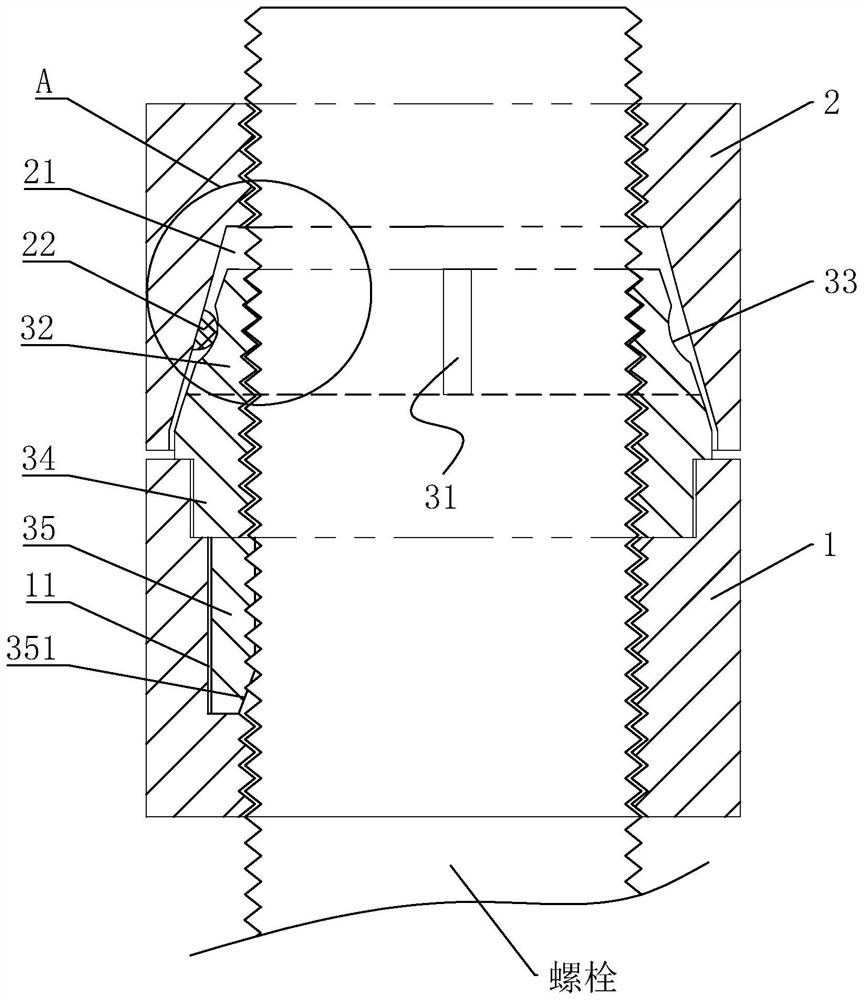

[0023] A high-strength anti-loosening nut, such as figure 1 and figure 2 As shown, it includes a first nut 1 and a second nut 2 that cooperate with each other;

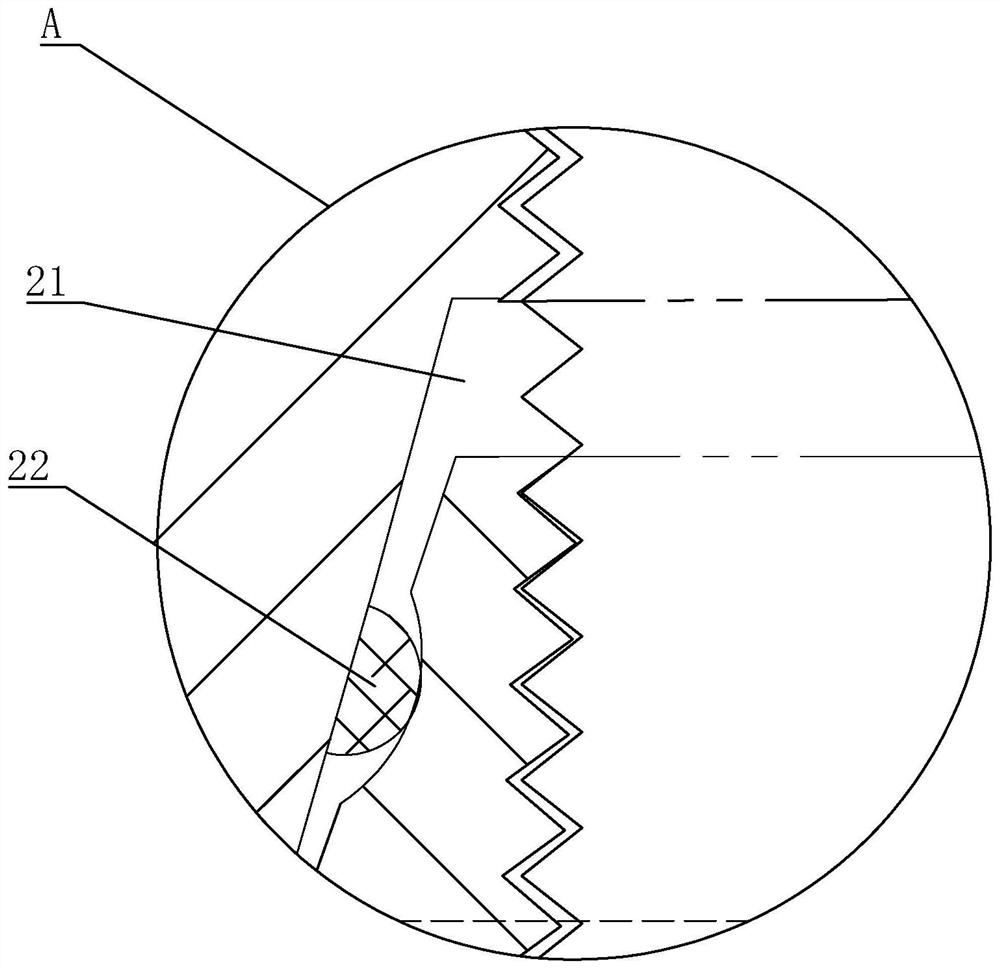

[0024] The end of the first nut 1 opposite to the contact object is the contact end, and the end facing away from the object is the connection end. The connection end is provided with a concentric limit ring 3 with internal threads on the same helical line. The limit ring 3 is Conical shape, its outer diameter gradually decreases from the opposite connection end to the back connection end. The end of the limit ring 3 facing away from the connection end is provided with a notch 31 in the axial direction that can deform locally after being s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com