Flat-plate evaporator optimized heat dissipation device

An evaporator and cover plate technology, which is applied to the field of optimized heat dissipation devices for flat plate evaporators, can solve the problems of reduced heat exchange performance of evaporators, long liquid replenishment paths of liquid absorbing wicks, and poor temperature uniformity of heat source surfaces, and achieves optimized heat exchange characteristics. , Improve the effect of uneven heat flow distribution and heat transfer characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

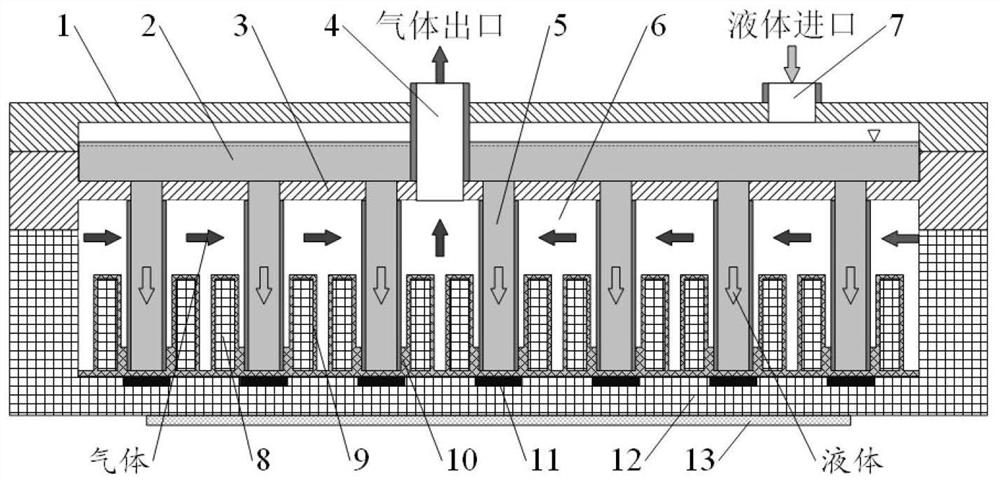

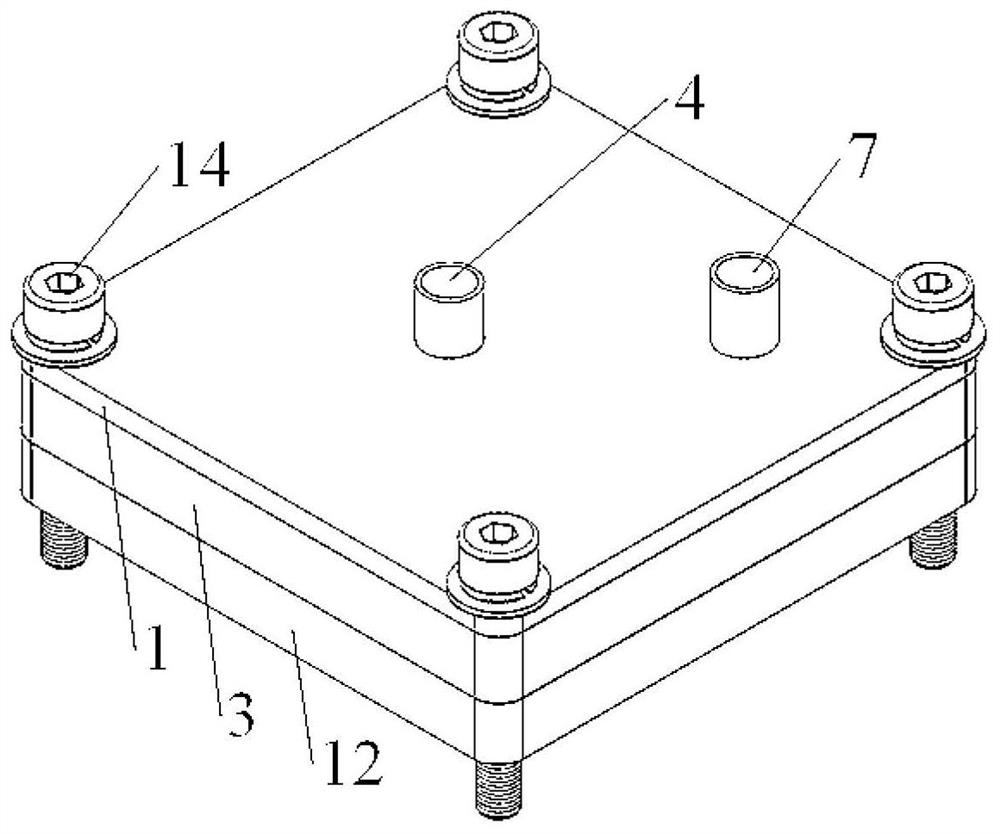

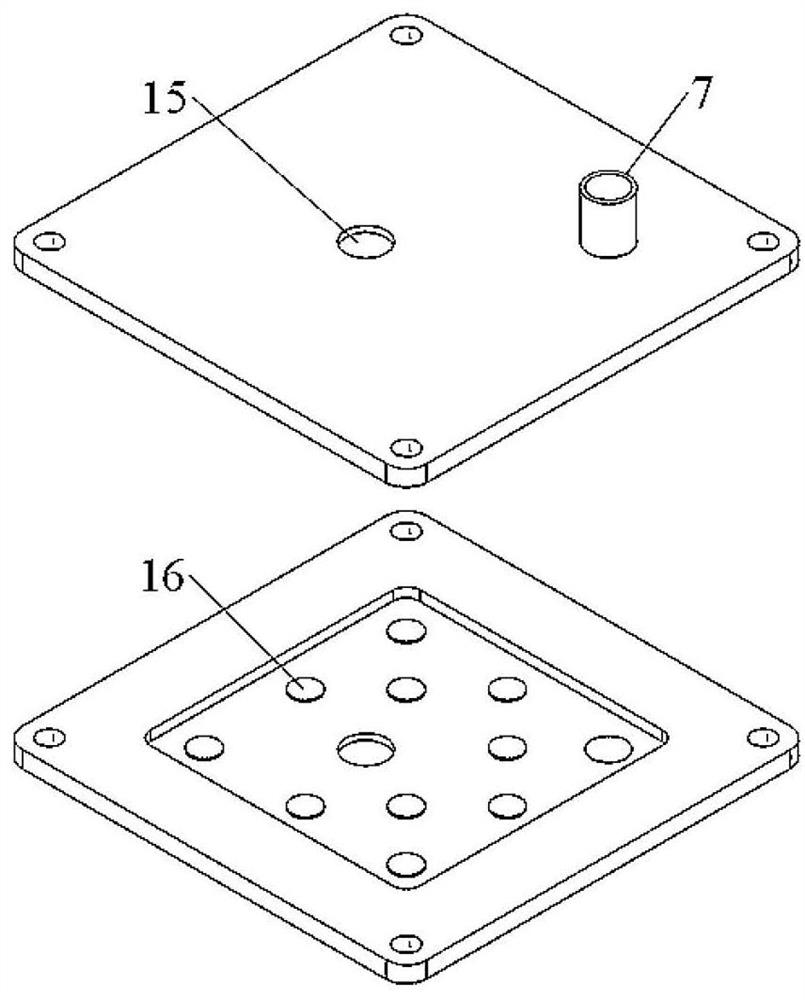

[0021] Such as figure 1 As shown, this embodiment relates to a flat-plate evaporator cooling device with a distributed liquid supply structure, including: a base 12, a housing composed of a gas-liquid chamber partition 3 and a cover plate 1, and a gas-liquid chamber arranged on the base 12. The evaporation gas chamber 6 between the chamber partitions 3, the liquid chamber 2 horizontally arranged between the gas-liquid chamber partition 3 and the cover plate 1, and several liquid supply conduits 5 vertically arranged in the gas-liquid chamber partition 3, Wherein: the liquid chamber 2 is in communication with the liquid supply conduit 5 and the housing is arranged on the heat source assembly 13 to be cooled, the liquid working medium at the outlet of the peripheral condensing equipment flows into the liquid chamber 2 through the liquid return pipe 7, and the working medium in the liquid chamber 2 It flows to the inner surface of the substrate 12 through the liquid supply condui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com