A kind of high-strength and high-transmittance polycarbonate film with wear-resistant surface for liquid crystal and preparation method thereof

A polycarbonate and high-strength technology, which is applied in the field of high-strength and high-transparency polycarbonate film and its preparation, can solve the problems such as the decrease of polycarbonate light transmittance, increase the filling amount, improve scratch resistance, and excellent The effect of translucency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

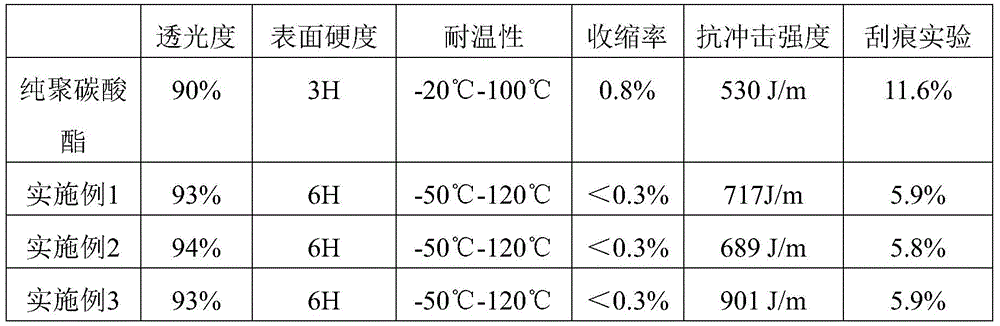

Embodiment 1

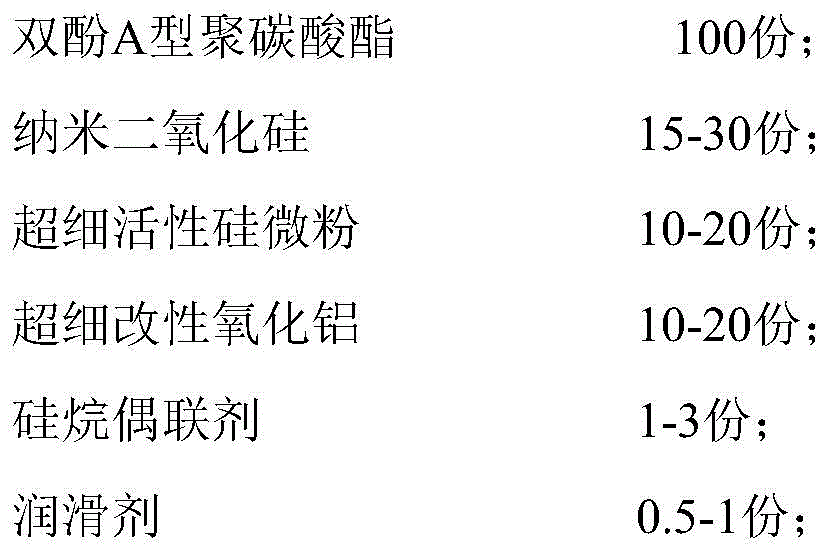

[0027] A high-strength and high-light-transmitting polycarbonate film with a wear-resistant surface for liquid crystal, the thickness of which is 0.05mm, and is composed of raw material bisphenol A polycarbonate, nano-silicon dioxide, ultra-fine active silicon powder, ultra-fine modified oxide Aluminum, a silane coupling agent and a lubricant are prepared. According to the weight parts, the weight parts of the above-mentioned raw materials are:

[0028] 100 parts of bisphenol A polycarbonate (molecular weight is 50,000-100,000);

[0029] Nano silica (SiO 2 The content is more than 99.8%, the particle size is 200-400nm, and the specific surface area is 200±50m 2 / g) 15 copies;

[0030] Ultrafine active silicon powder (400-2000 mesh, loose bulk density 1330kg / m 3 ) 10 copies;

[0031] Ultrafine modified alumina (particle size is 200nm-2um, obtained by graft copolymerization of alumina and acryloyl chloride in a ratio of 4:1 by mass, the reaction temperature is 25°C, and the ...

Embodiment 2

[0040] A high-strength and high-transmittance polycarbonate film with a wear-resistant surface for liquid crystal, the thickness of which is 0.20mm, and is composed of raw material bisphenol A polycarbonate, nano-silicon dioxide, ultra-fine active silicon powder, ultra-fine modified oxide Aluminum, a silane coupling agent and a lubricant are prepared. According to the weight parts, the weight parts of the above-mentioned raw materials are:

[0041] 100 parts of bisphenol A polycarbonate (molecular weight is 50,000-100,000);

[0042] Nano silica (SiO 2 The content is more than 99.8%, the particle size is 200-400nm, and the specific surface area is 200±50m 2 / g) 30 copies;

[0043] Ultrafine active silicon powder (400-2000 mesh, loose bulk density 1330kg / m 3 ) 20 copies;

[0044] Ultrafine modified alumina (particle size is 200nm-2um, obtained by graft copolymerization of alumina and acryloyl chloride in a ratio of 4:1 by mass, the reaction temperature is 25°C, and the react...

Embodiment 3

[0049] A high-strength and high-transmittance polycarbonate film with a wear-resistant surface for liquid crystal, the thickness of which is 0.15mm, and is composed of raw material bisphenol A polycarbonate, nano-silicon dioxide, ultra-fine active silicon powder, ultra-fine modified oxide Aluminum, a silane coupling agent and a lubricant are prepared. According to the weight parts, the weight parts of the above-mentioned raw materials are:

[0050] 100 parts of bisphenol A polycarbonate (molecular weight is 50,000-100,000);

[0051] Nano silica (SiO 2 The content is more than 99.8%, the particle size is 200-400nm, and the specific surface area is 200±50m 2 / g) 25 copies;

[0052] Ultrafine active silicon powder (400-2000 mesh, loose bulk density 1330kg / m 3 ) 15;

[0053] Ultrafine modified alumina (particle size is 200nm-2um, obtained from the graft copolymerization reaction of alumina and acryloyl chloride in a mass ratio of 4:1, the reaction temperature is 25°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com