Defect detection method and device based on rotary carrying table

A defect detection and stage technology, which is used in measurement devices, optical testing of flaws/defects, and material analysis by optical means. It can solve problems such as repeated scanning and adding optical systems to improve detection efficiency and imaging efficiency. , the effect of reducing the cost of optics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

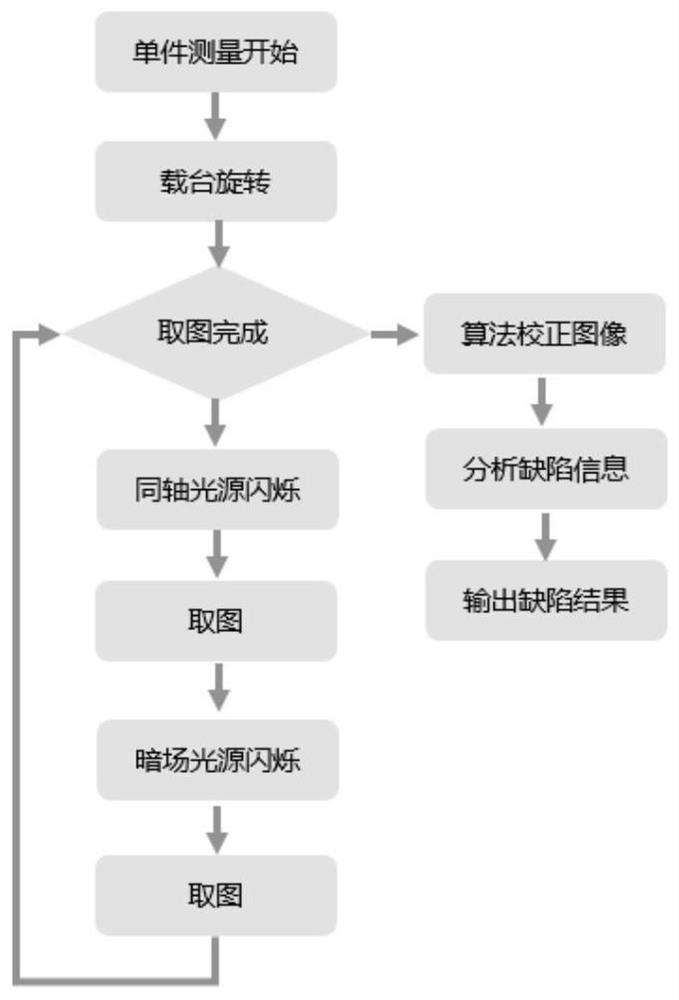

[0049] Embodiment 1 proposes a preferred defect detection method based on a rotating stage, the flow chart of which is as follows figure 1 As shown, when the single piece / one piece measurement starts, the stage starts to rotate, and the line scan camera is perpendicular to the direction of circular motion. When the test object passes the line scan camera, the bright field light source starts to flicker, and the line scan camera exposes the bright field image once , and then the dark-field light source starts to flicker, and the line-scan camera exposes the dark-field image once. Among them, the bright-field light source and the dark-field light source flash alternately, and the line-scan camera takes images of two different light sources respectively until the complete bright-field line-scan image and dark-field line-scan image of the object to be detected are respectively taken, Then the bright-field line-scan image and the dark-field line-scan image are spliced to form a b...

Embodiment 2

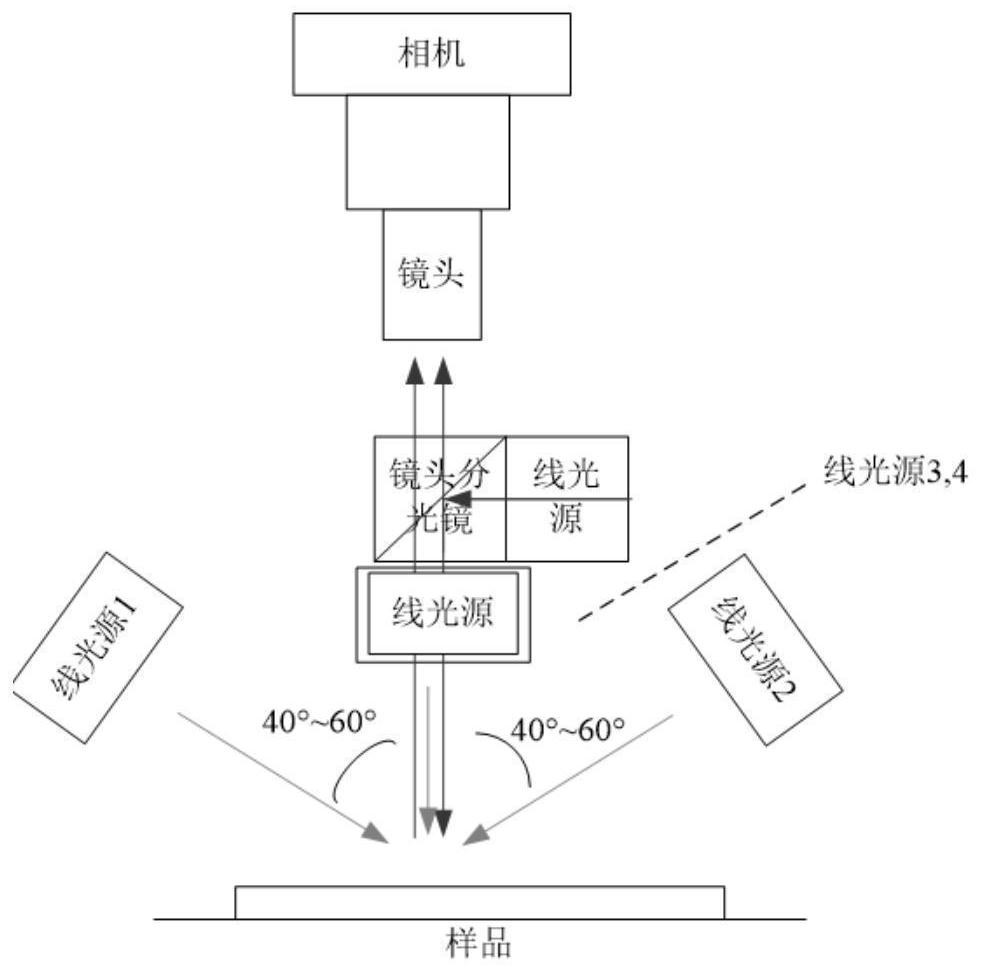

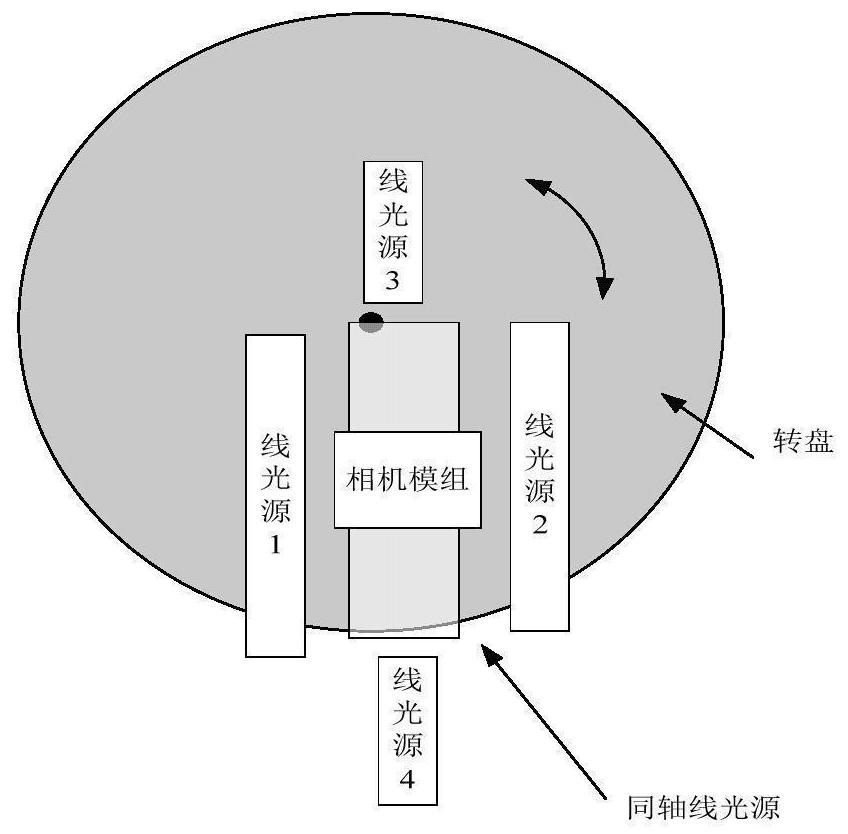

[0051] Embodiment 2 proposes a preferred defect detection device based on a rotating stage, such as figure 2 and image 3 As shown, the device includes a rotating stage, a line-scan camera, and a processing module. The rotary stage includes a turntable, a motor, and an encoder; the line-scan camera includes a lens and a camera, and the processing module includes a calculator module. Among them, the rotating stage drives the detection object / sample to make a circular motion; the line-scan camera is located above the rotation stage and the imaging direction is perpendicular to the direction of circular motion; the line-scan camera obtains the line-scan image of the detection object / sample; the processing module is based on the line-scan image Perform defect detection and obtain defect information.

[0052] The detection device also includes a fixing device, and the detection object is fixed by the fixing device. The fixing device may be a vacuum suction device, or any other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com