Wind power rotary support surface defect detection method

A technology of slewing support and defect detection, which is applied in image processing or feature extraction combined with machine learning for defect detection, and in the field of collecting specific texture images on the surface of wind power slewing supports, which can solve the problem of relying on manual observation, The amount of calculation is difficult to meet the real-time industrial detection, the surface of the wind power slewing support is easy to reflect light, etc., to achieve the effect of fast calculation speed, reduced calculation amount, and improved reliability and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the scope of the present invention.

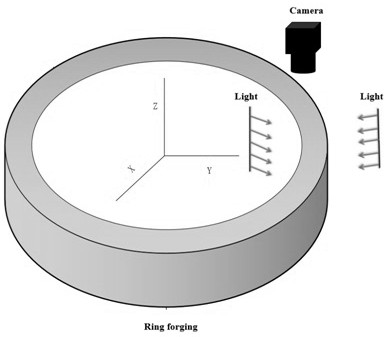

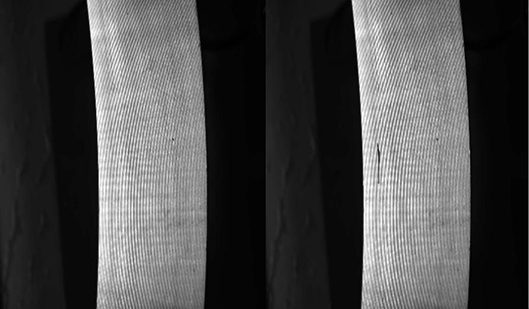

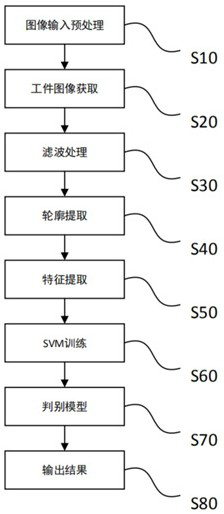

[0044] In the present invention, a specific detection algorithm is designed by using the texture features exhibited under low-angle illumination, and the image acquisition device such as figure 1 . Firstly, the image I is obtained by shooting the image I with the bar-shaped light source facing the lighting, and the angle is roughly set at 15°. The example of the collected image is as follows figure 2 , convert the image I into a grayscale image, and use Gaussian filtering to denoise the obtained grayscale image, perform morphological opening operation on the image, then use the QTSU method to binarize the image, and then use feature extraction combined with SVM train...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com