Device for producing filter rod for tobacco processing industry

A processing industry and filter strip technology, which is applied in the fields of tobacco, smoke oil filter element, application, etc., can solve the problems of difficult operation of filter strips, addition of filament materials for filtration, etc., and achieve high insertion accuracy, small tolerance, and improved tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

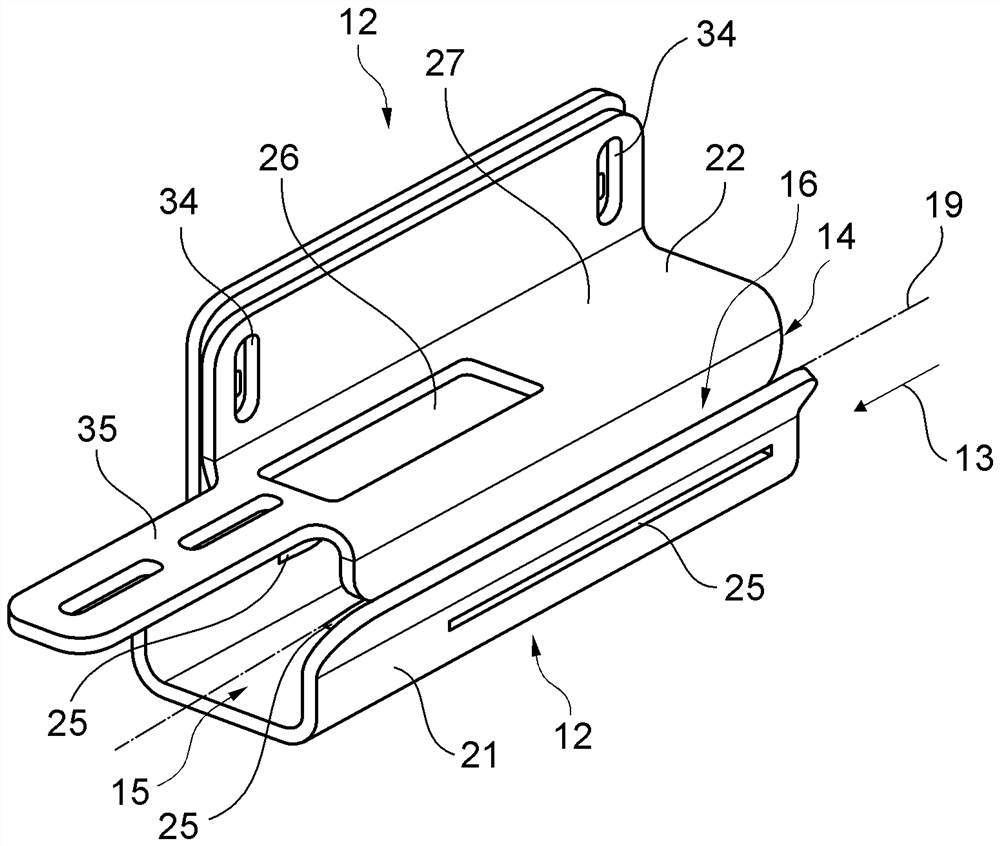

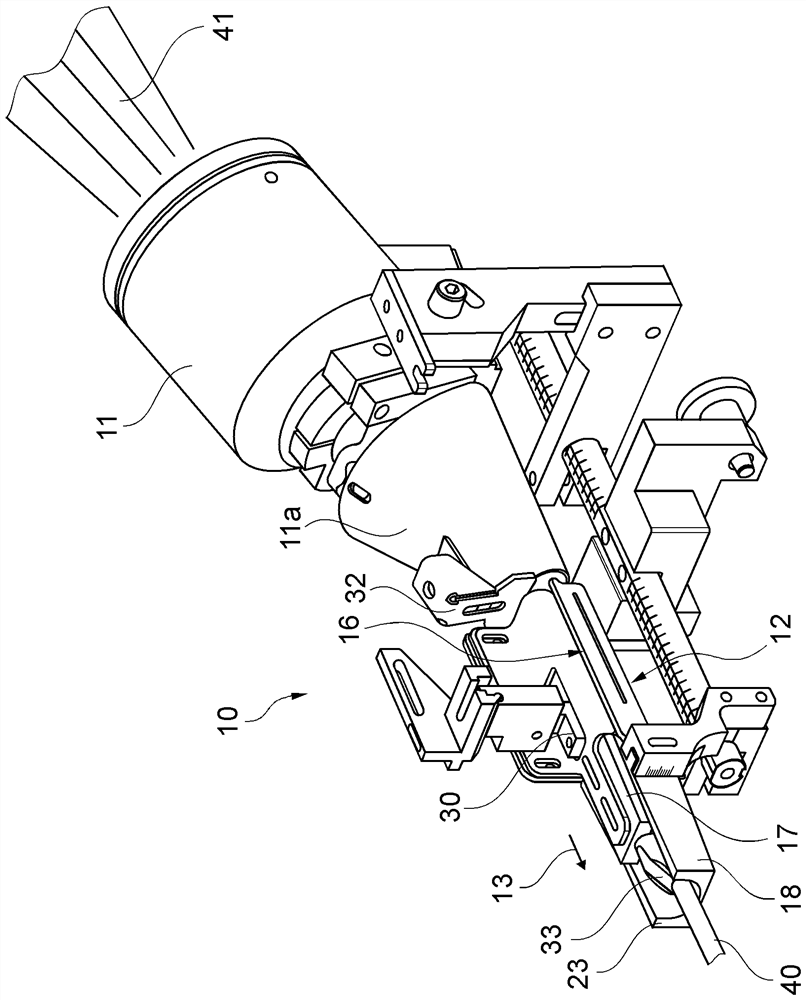

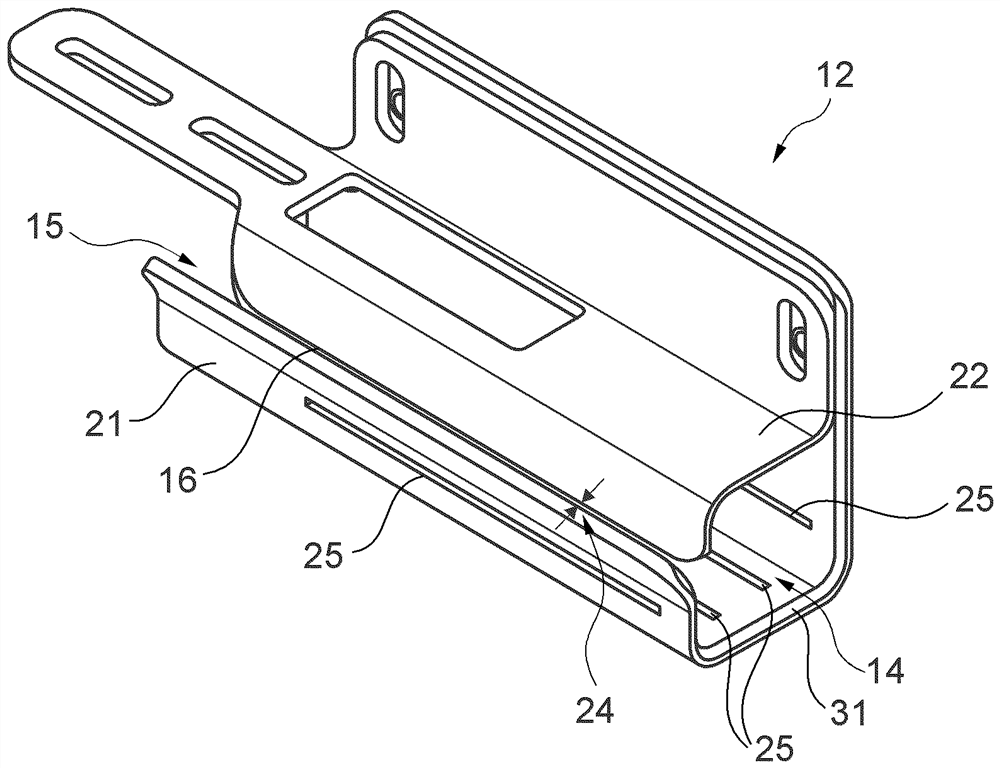

[0030] figure 1 A part of a device for producing a filter rod 10 is shown schematically in three dimensions. The filter material 41 can be, for example, a filter filament, which is fed according to the usual preprocessing steps to the conveying nozzle 11, in which the filter filament material 41 is passed through the air belonging to the conveying nozzle 11 with compressed air. The outlet funnel 11a leads to a conduit 12, from which the filter material 41 is conveyed to a sizing device 23 in order to be subsequently formed into a filter rod 40 in said sizing device 23, wherein only the Got small portions. For example, wrapping material is wound around the filter material 41 in the format device 23 and a round or oval filter rod 40 is produced, which can then be cut to length by means of a common cutter device with a predetermined A filter rod of a given length.

[0031] The standard device 23 has a lower standard part 18 and an inlet tongue 17, wherein also only part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com