Ore crushing treatment device

A processing device and ore crushing technology, applied in the field of ore mining, can solve the problems of insufficient crushing, inclusion of large-volume ore blocks, inconvenient processing, etc., to ensure the crushing effect, improve production quality, improve crushing effect and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

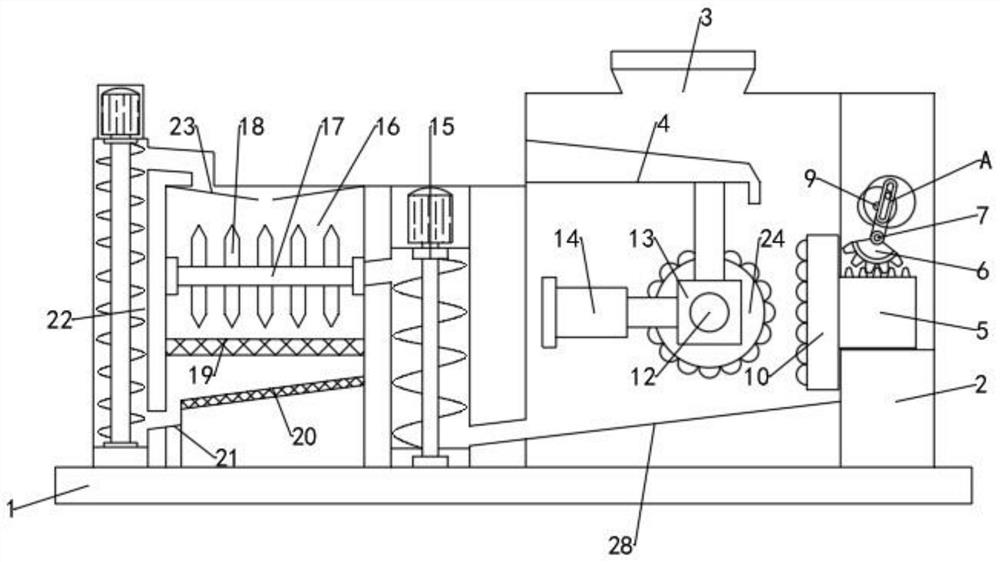

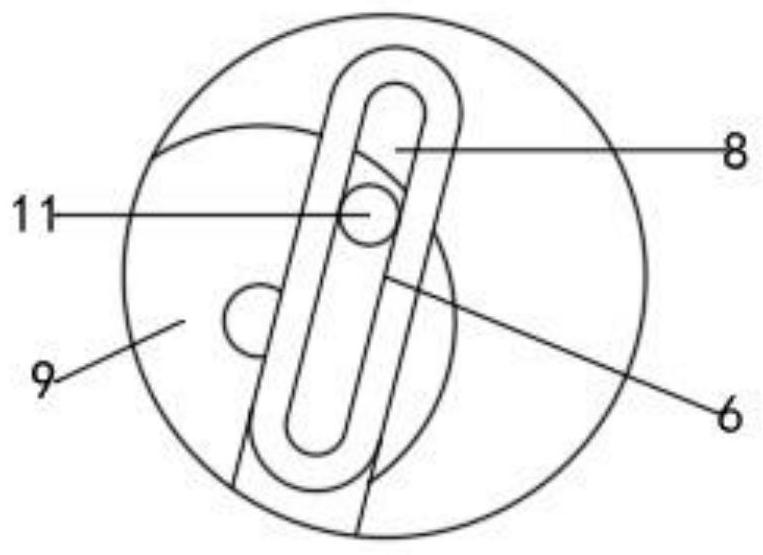

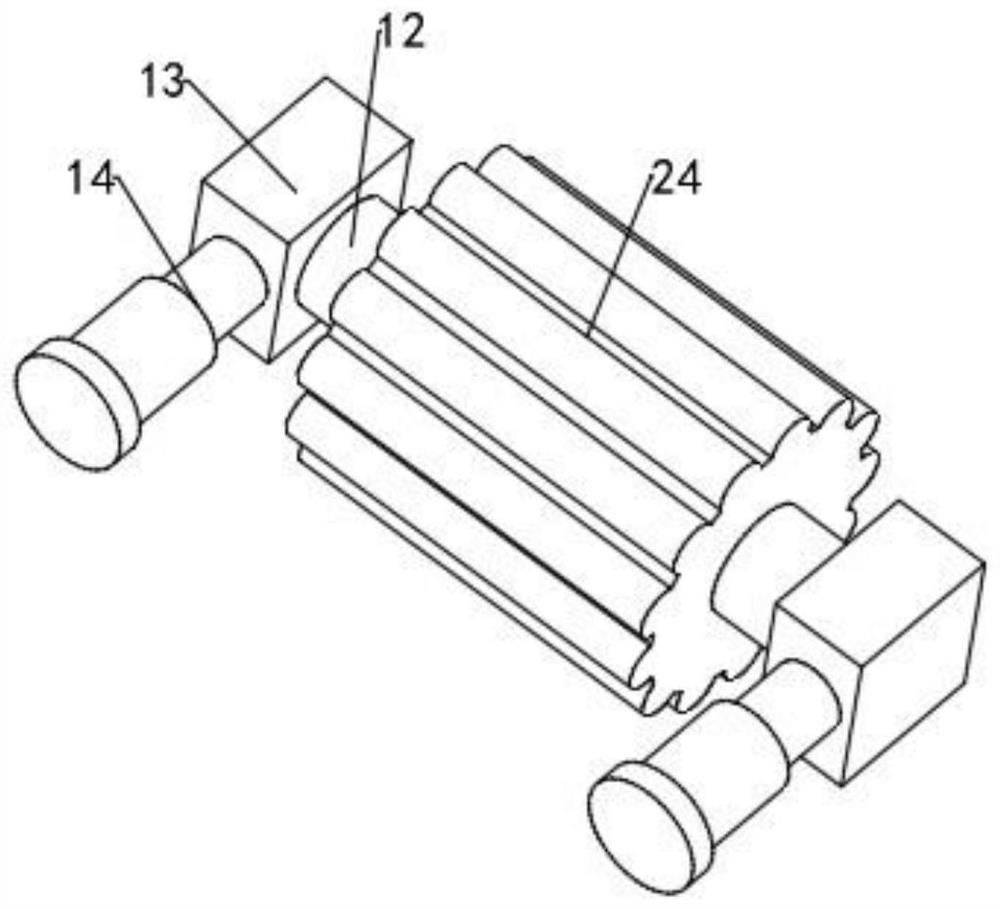

[0020] see Figure 1-4 , an ore crushing and processing device, comprising a base 1, a crushing chamber 2 is arranged on one side of the upper end surface of the base 1, and a crushing mechanism is connected to one side of the crushing chamber 2 through a first conveyor 15; the crushing chamber 2 is a hollow structure, and the upper end of the crushing chamber 2 is provided with a feed hopper 3, and the inner side of the crushing chamber 2 is fixedly connected with an inclined first material guide plate 4; the inside of the crushing chamber 2 is slidably connected with an assembly seat 13, The number of assembly seats 13 is two and arranged at intervals. The two assembly seats 13 are equipped with crushing rollers 24 through the rotating shaft 12. The rotating shaft 12 extends to the inside of the crushing chamber 2. One side of the assembly seat 13 is connected with an adjusting cylinder 14. The adjusting cylinder 14 is assembled in the inside of the crushing chamber 2, and o...

Embodiment 2

[0029]In Embodiment 1, the primary crushed ore is conveyed into the crushing chamber 16 by the first conveyor 15, and the crushing blades inside the crushing chamber 16 further crush the ore and pass through the screening of the discharge net 20, and the insufficiently crushed ore passes through the second crushing chamber 16. The conveyor 22 is transported into the crushing chamber 16 again. In order to facilitate the ore to enter the crushing chamber 16 evenly again, this embodiment is improved on the basis of Embodiment 1. The improvement is: the inner upper part of the crushing chamber 16 is arranged There is a funnel-shaped second material guide plate 23, so that the ore enters from the inner middle position of the crushing cavity 16, and is convenient to crush.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com