Blade surface rust stain treatment device for centrifugal pump maintaining

A processing device and centrifugal pump technology, applied in the field of centrifugal pumps, can solve the problems of heavy workload, inconvenient use, and low work efficiency, and achieve the effect of reasonable device, convenient use, and guaranteed cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

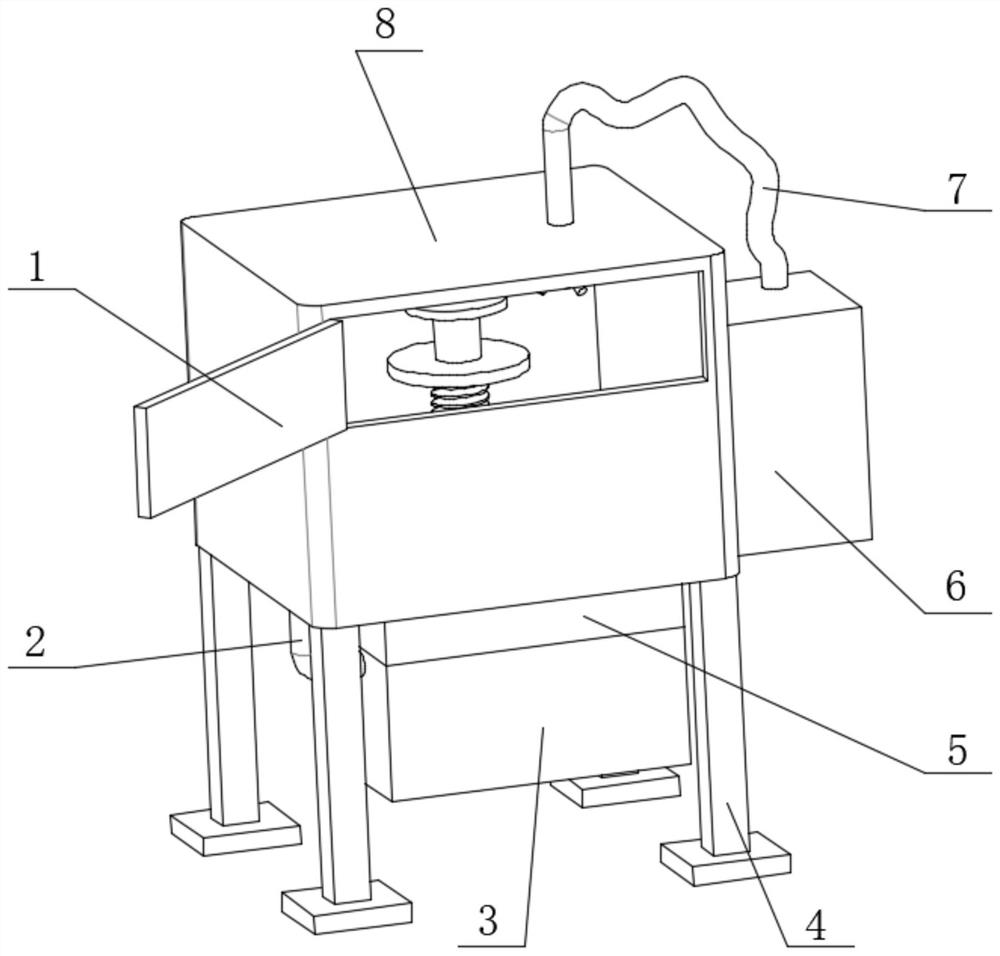

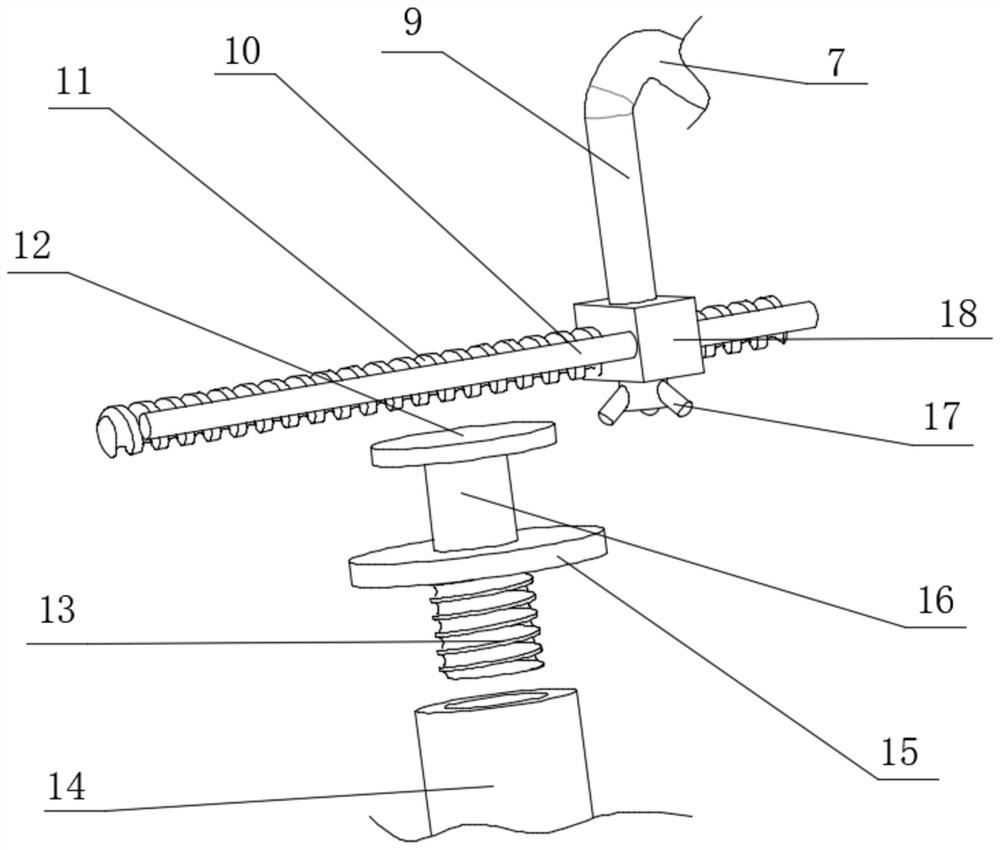

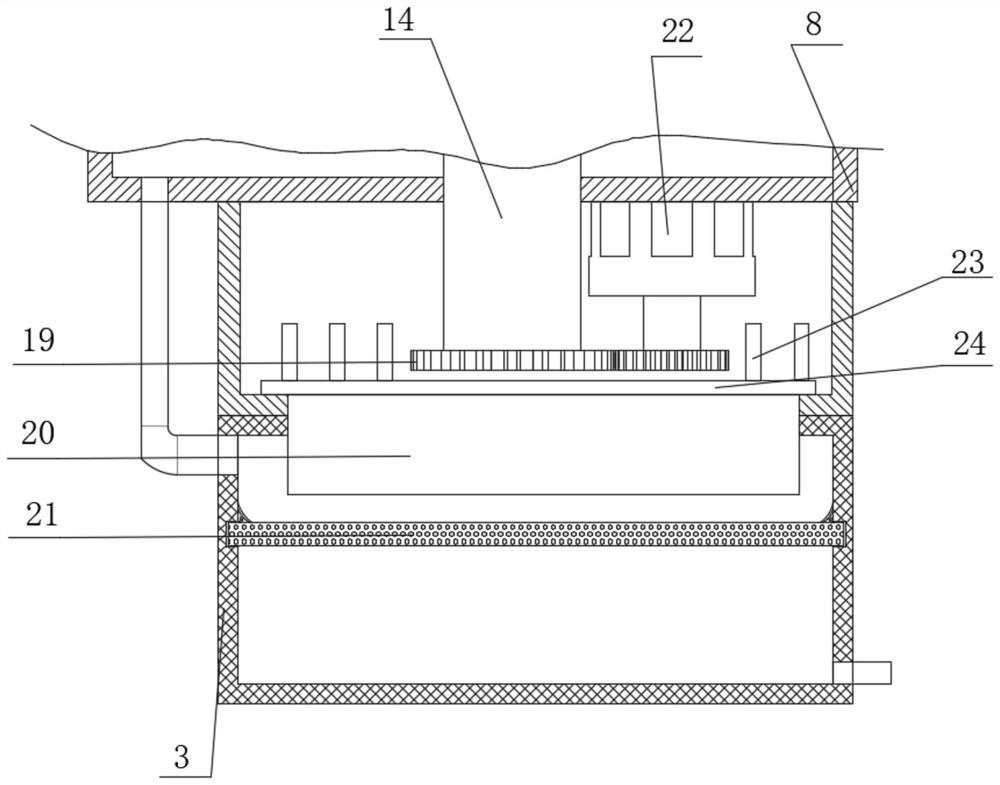

[0029] refer to Figure 1-4 , a centrifugal pump maintenance blade surface rust treatment device, including a treatment shell 8, the bottom inner wall of the treatment shell 8 is rotatably connected with a rotating shaft 14, and the outer wall of the top of the rotating shaft 14 is provided with a threaded hole, and the inner wall of the threaded hole is rotated through the thread Connected with a threaded rod 13, the top outer wall of the threaded rod 13 is equipped with a circular block 15, and the top outer wall of the circular block 15 is equipped with a circular rod 16, and the outer wall of the circular rod 16 is connected with an extruding ring 12 by thread rotation, and the processing shell The inner walls on both sides of the body 8 are rotatably connected with the same screw mandrel 11, and the outer wall of the outer wall of the screw mandrel 11 is rotatably connected with a sliding block 18. Equidistantly distributed liquid spray nozzles 17 are connected, and the l...

Embodiment 2

[0034] refer to Figure 1-5 , a centrifugal pump maintenance blade surface rust treatment device also includes a circular groove on the top outer wall of the circular block 15, and the inner wall of the circular groove is slidingly connected with a connecting ring 28, and the outer wall of the connecting ring 28 is equipped with equidistant distribution rings. buffer spring 30, the outer wall at the bottom of the buffer spring 30 is fixedly connected with the corresponding inner wall at the bottom of the circular groove.

[0035] Working principle: Compared with Example 1, the fixed blade can be squeezed by setting the circular block 15, the connecting ring 28 and the buffer spring 30, which further improves the firmness of the fixation and facilitates the subsequent processing quality. Make the device more perfect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com