Transceiver assembly positioning tool

A technology for sending and receiving components and positioning tooling, which is applied in auxiliary devices, manufacturing tools, metal processing, etc., can solve problems such as troublesome positioning operations, affecting welding quality, and uneven and sufficient melting of solder paste, etc., to achieve high positioning effect, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

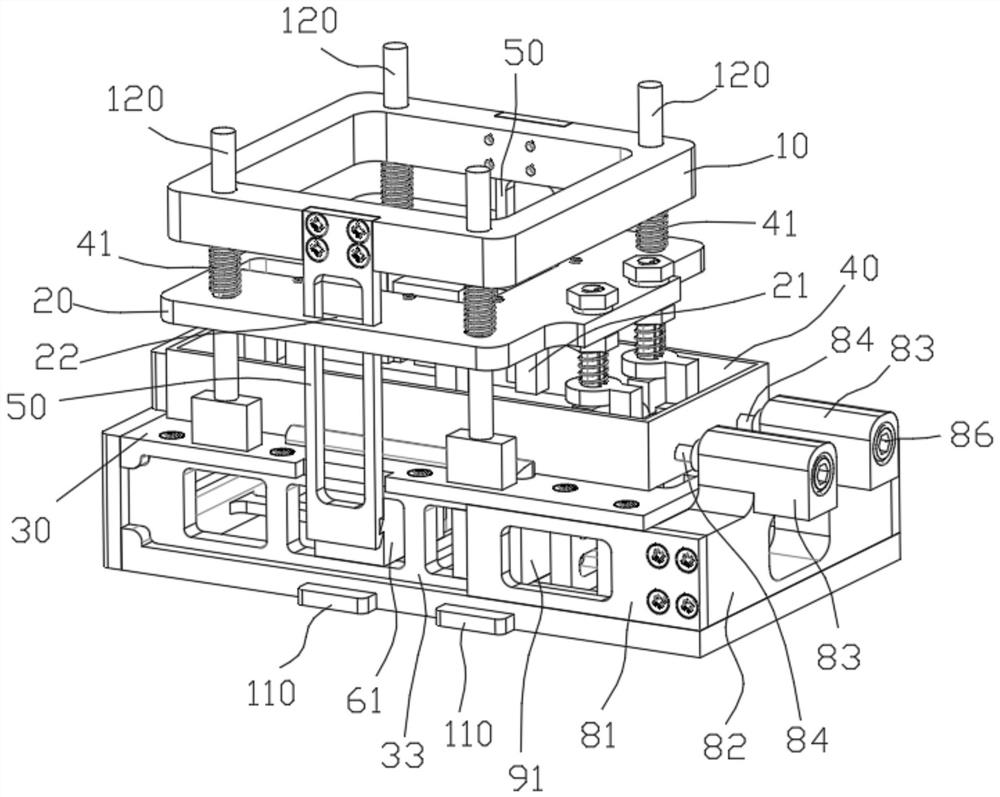

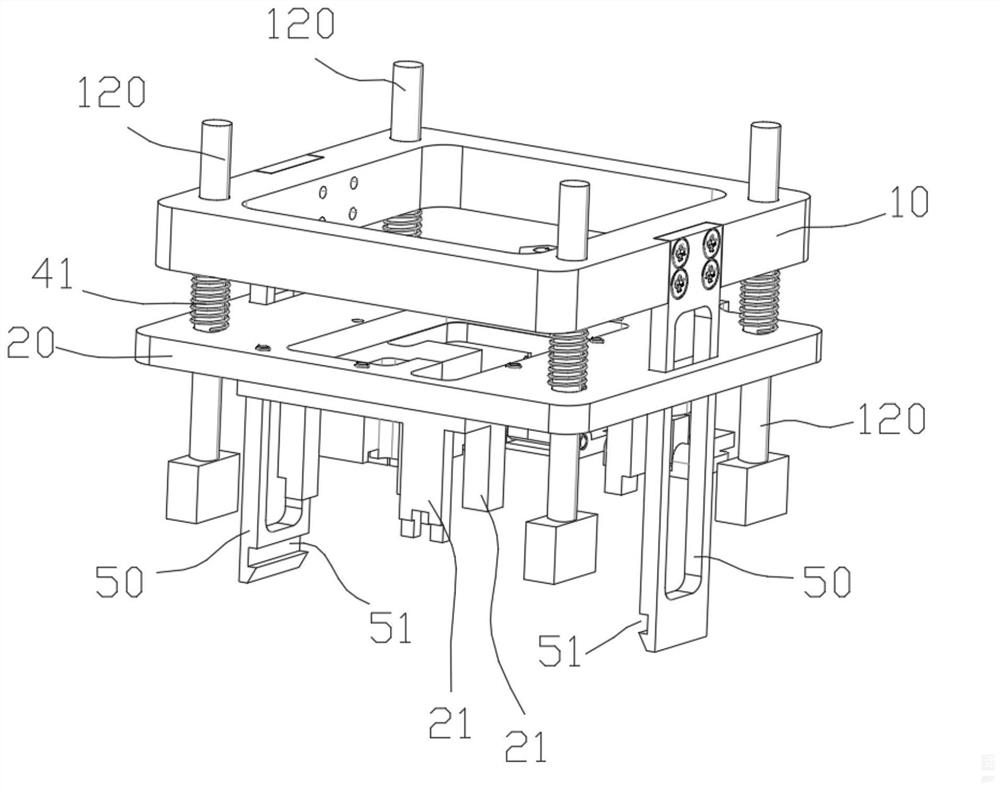

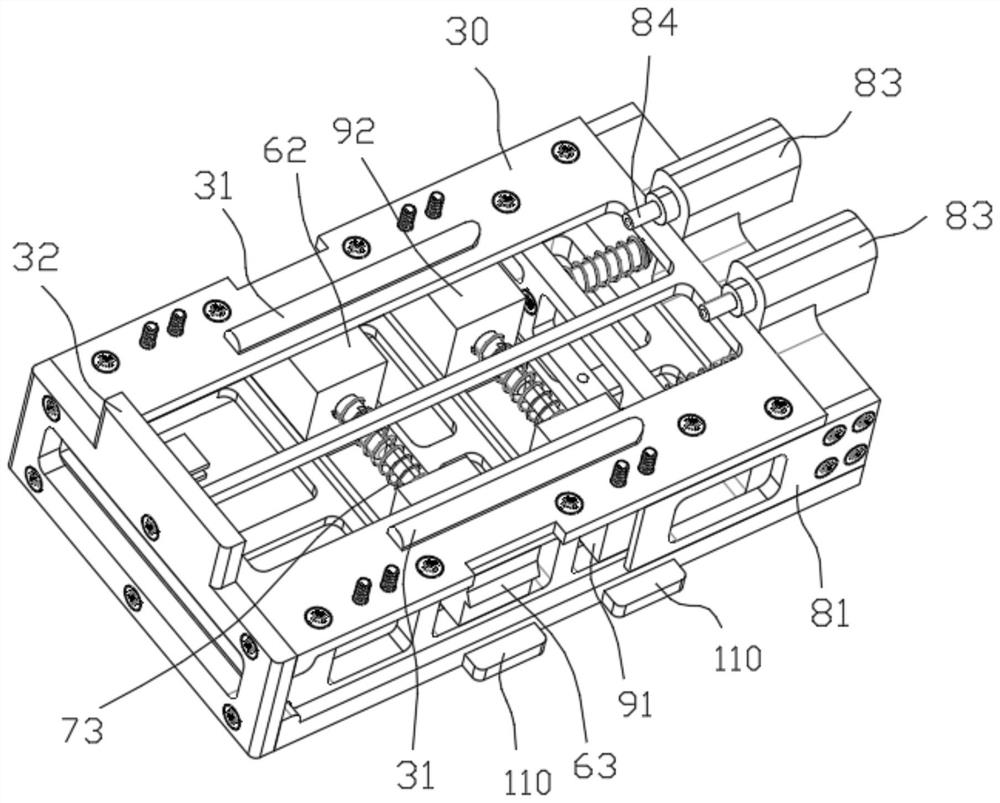

[0019] Such as Figure 1-6 As shown, the positioning tooling of the transceiver assembly of this embodiment includes an upper press frame 10, a lower press frame 20, a frame-like base 30 and a box body 40 of the transceiver assembly. The components are placed inside the box body 40, and the box body 40 is placed on the base In the limiting groove on the upper surface of the base 30, a plurality of guide columns 120 are vertically arranged around the upper surface of the base 30, and the upper pressing frame 10 is arranged in parallel above the lower pressing frame 20 and both are arranged above the base 30. All the guiding columns 120 Pass freely through the through hole of the upper pressing frame 10 and the through hole of the lower pressing frame 20 respectively, and the spring one 41 is sleeved on the guide column 120, and the two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com