Powder material adding device for concrete production

A technology of adding device and concrete, which is applied in the direction of unloading device and selling raw material supply device, etc., which can solve the problems of inability to mix powder materials and loss, and achieve the effects of saving manpower, precise powder ratio and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

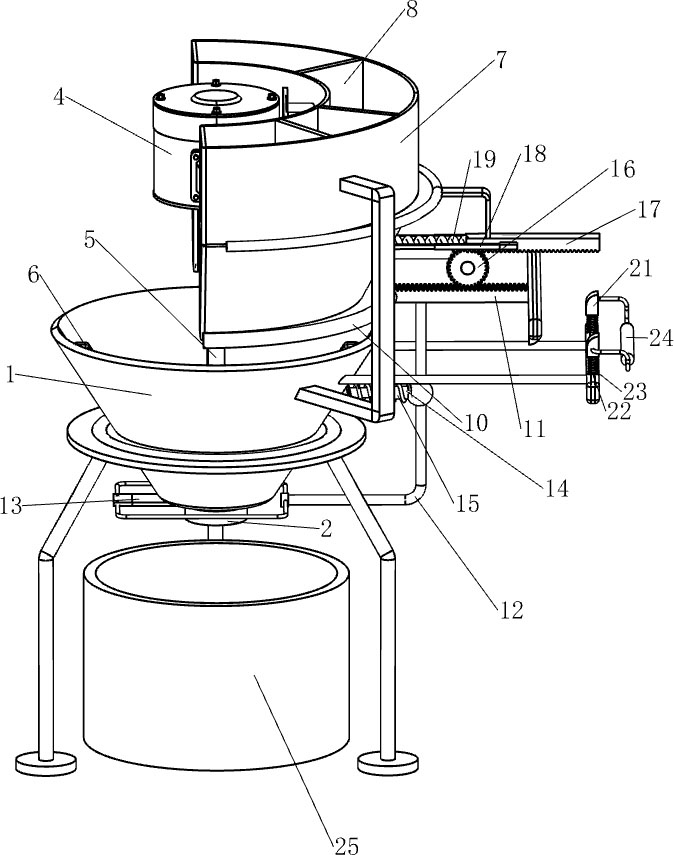

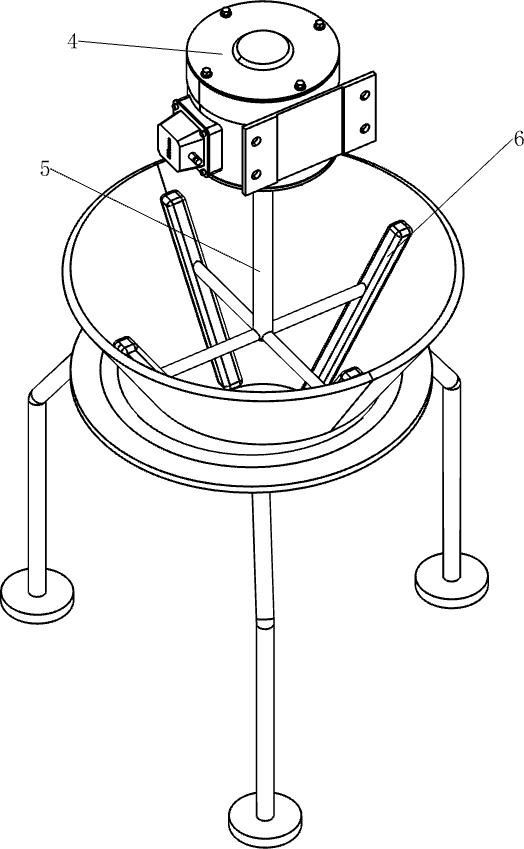

[0020] A kind of powder adding device for concrete production, such as Figure 1-3 As shown, it includes a mixing body 1, a material receiving box 25, a feeding assembly and a stirring assembly. Box 25, the top of the mixing body 1 is fixedly connected with a blanking assembly through a moving mode for blanking by bolts, and the left side of the blanking assembly is provided with a stirring assembly powered by a motor.

[0021] When using the device to add powder, first put the powder into the feeding assembly, control the feeding assembly so that the internal powder enters the mixer body 1, control the stirring assembly to work, and control the powder in the mixer body 1 Stir, and after the stirring is completed, control the stirring assembly to stop working, and the stirred powder flows out from the feeding port 2 into the receiving box 25.

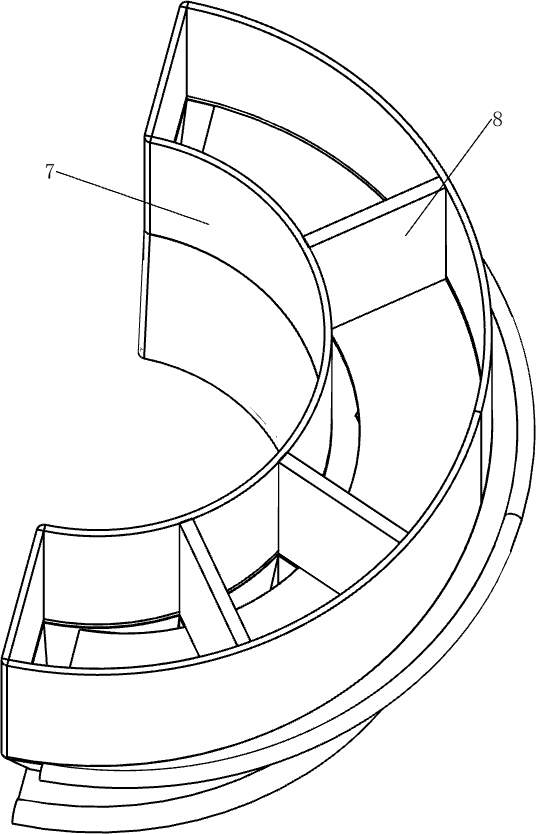

[0022] The blanking assembly includes a quantitative storage box 7, a partition plate 8 and a fitting plate 10, and the quantitative ...

Embodiment 2

[0027] On the basis of Example 1, such as figure 1 , 4 Shown in and 5, also include the first rack 11, link rod 12, blocking material block 13, tension spring 14, the first telescopic link 15, gear 16, the second rack 17, quantitative plate 171, telescopic guide block 18 and return spring 19, the right side of the fitting plate 10 is fixedly connected with the first rack 11 by bolts, the bottom of the first rack 11 is fixedly connected with the connecting rod 12, and the left end of the lower part of the connecting rod 12 is provided with a blocking material block 13 through the return ring , the blocking material block 13 is slidably connected in the card slot 3, the first telescopic rod 15 is welded in the middle of the link rod 12, and the left side of the first telescopic rod 15 is fixed on the mixer body 1 by bolts, the first telescopic rod 15 is connected with the mixer The body 1 is connected with a tension spring 14, and the bottom right side of the storage quantitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com