High-stability gear transportation logistics vehicle of vehicle

A high-stability, logistics vehicle technology, applied in the field of logistics vehicles, can solve the problems of inaccurate fixation, low transportation efficiency, easy shaking, etc., and achieve the effect of simple and reliable structure, convenient disassembly, and avoiding bruises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

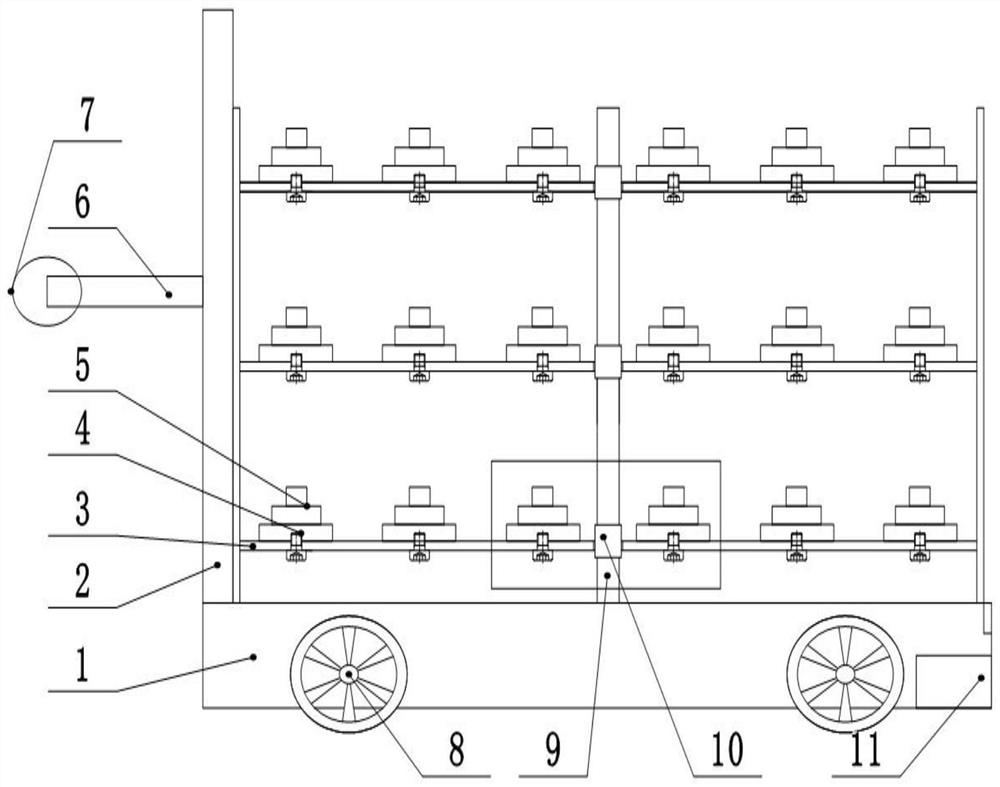

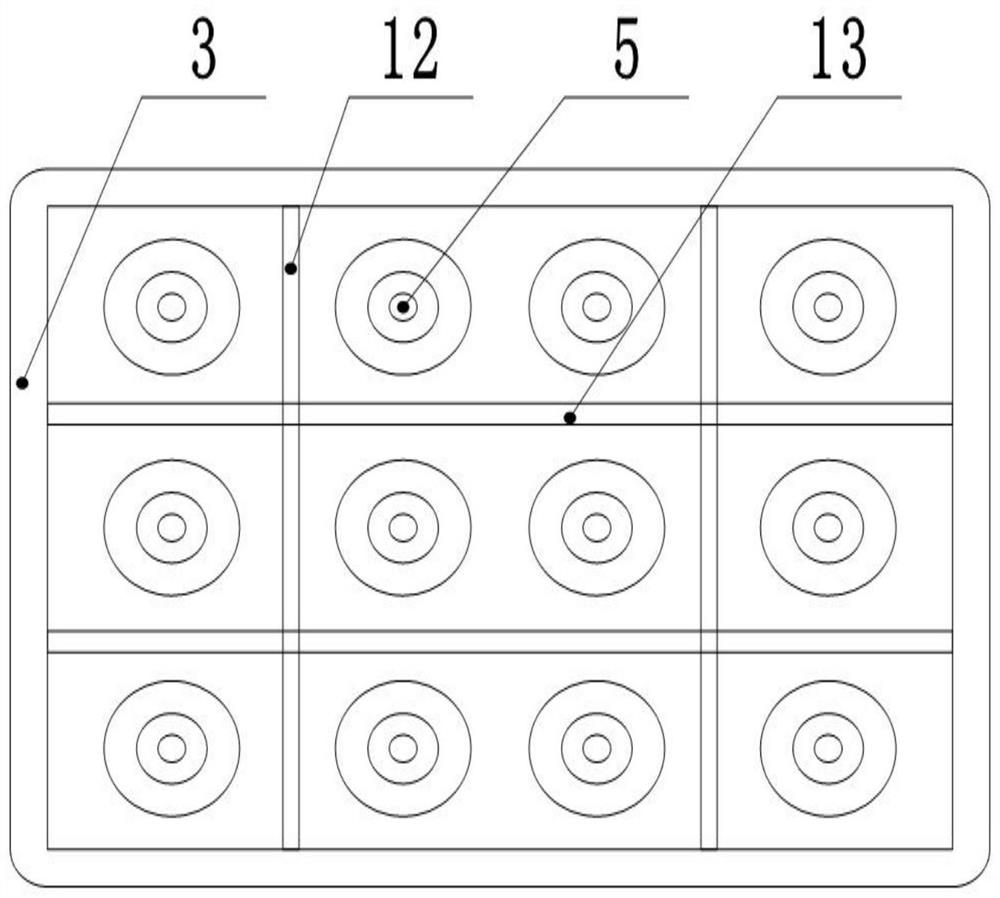

[0018] see figure 1 , an automobile high-stability gear transport logistics vehicle, comprising: a chassis 1, a side column 2, a horizontal plate 3, wheels 8, a handle bar 6, a handle 7, a vertical bar 9 and a chassis installation block 10, and the chassis 1 adopts It is stamped from an aluminum alloy profile with good mechanical properties and light weight. Two pairs of wheels 8 are installed symmetrically on both sides of the chassis 1. The outer sides of the wheels 8 are wrapped with rubber pads, which are silent and non-slip. The upper left corner of the chassis 1 is welded and installed There is a side column 2, a handle bar 6 is arranged on the left side of the side column 2, and a handle 7 is installed in the middle of the handle bar 6, which is convenient for pushing the logistics vehicle or fixing the traction equipment. The lower right corner of the chassis 1 is provided with a counterweight 11, Counterweight 11 is cast iron block, can carry out the adjustment of pos...

Embodiment 2

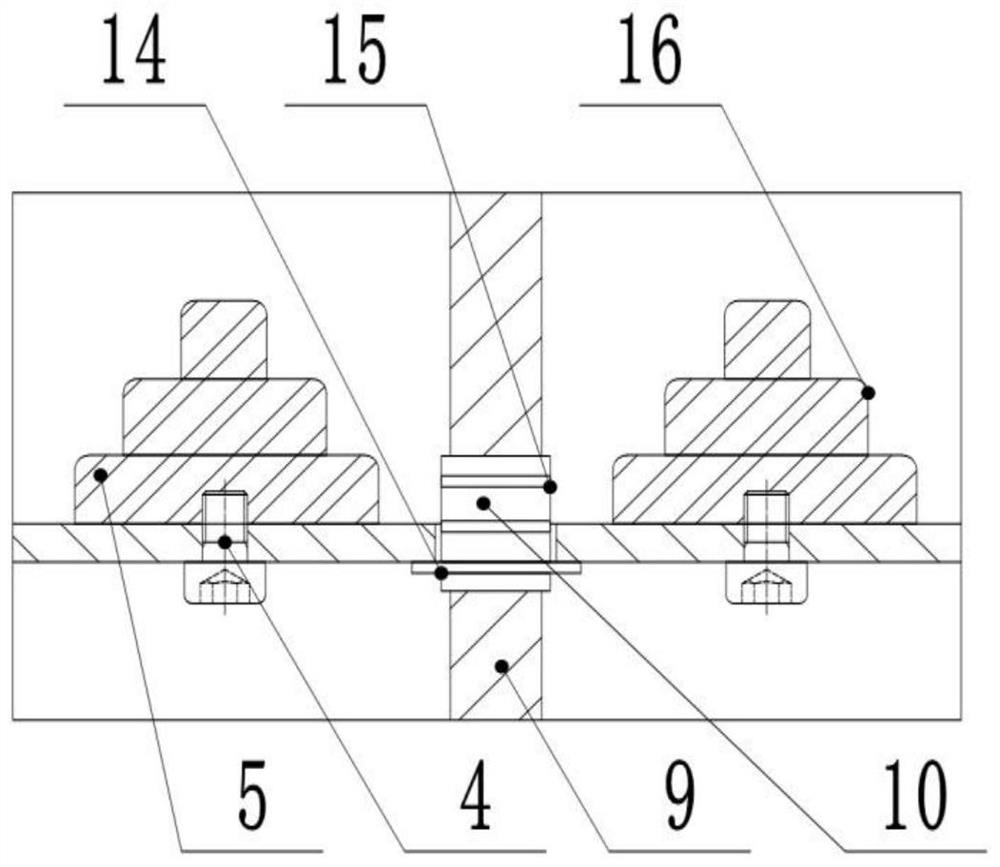

[0020] Compared with Embodiment 1, the second embodiment is only different in that a chamfering belt 16 is provided on the outside of the positioning block 5, and the design of the chamfering belt 16 reduces interference during the pick-and-place process of parts and improves work efficiency.

[0021] Technical principle: The positioning pin 14 is used to fix in the corresponding positioning pin hole 15, the horizontal plates 3 on both sides are placed on the positioning pins 14 to complete the fixing, and the corresponding positioning block 5 is selected to be quickly installed on the top of the horizontal plate 3 through the installation screw 4. Place the parts on the outside of the positioning block 5, and install and place the upper layer after completing one layer. This design structure is simple and reliable, easy to disassemble, compatible with parts of various sizes, and can effectively prevent parts from colliding with each other. powerful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com