Multifunctional raw material warehousing system

A warehousing system and multifunctional technology, applied in the field of raw material warehousing system and multifunctional raw material warehousing system, can solve problems such as troubles, and achieve the effects of simple operation, low production cost and increased work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing provides the preferred embodiment of the present invention, what is disclosed is only the preferred embodiment of the present invention, certainly can not limit the scope of rights of the present invention with this, therefore the equivalent change made according to the claims of the present invention , still belong to the scope covered by the present invention.

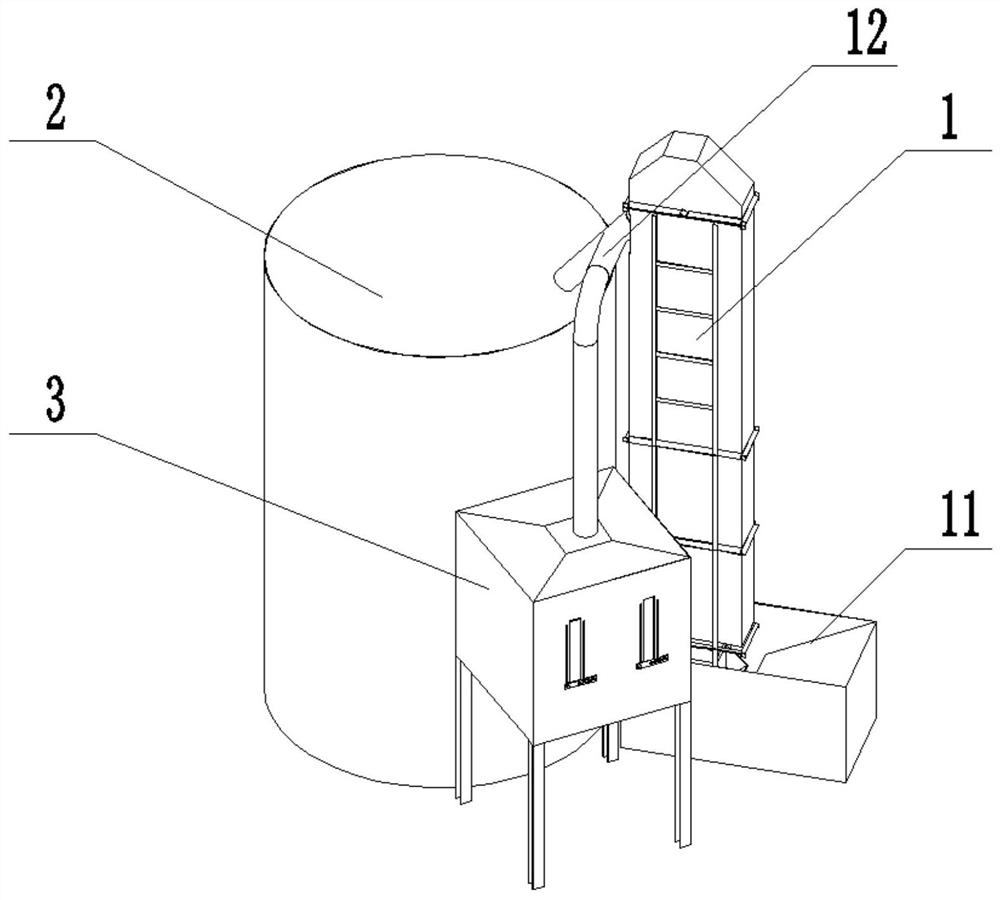

[0024] See figure 1 As shown, a multifunctional raw material storage system disclosed by the present invention includes a hoist 1, a storage bin 2, and a distribution bin 3; Divide the material when feeding; the material inlet of the hoist 1 is provided with a feed trough 11, and the outlet of the hoist 1 is provided with a tee device 12;

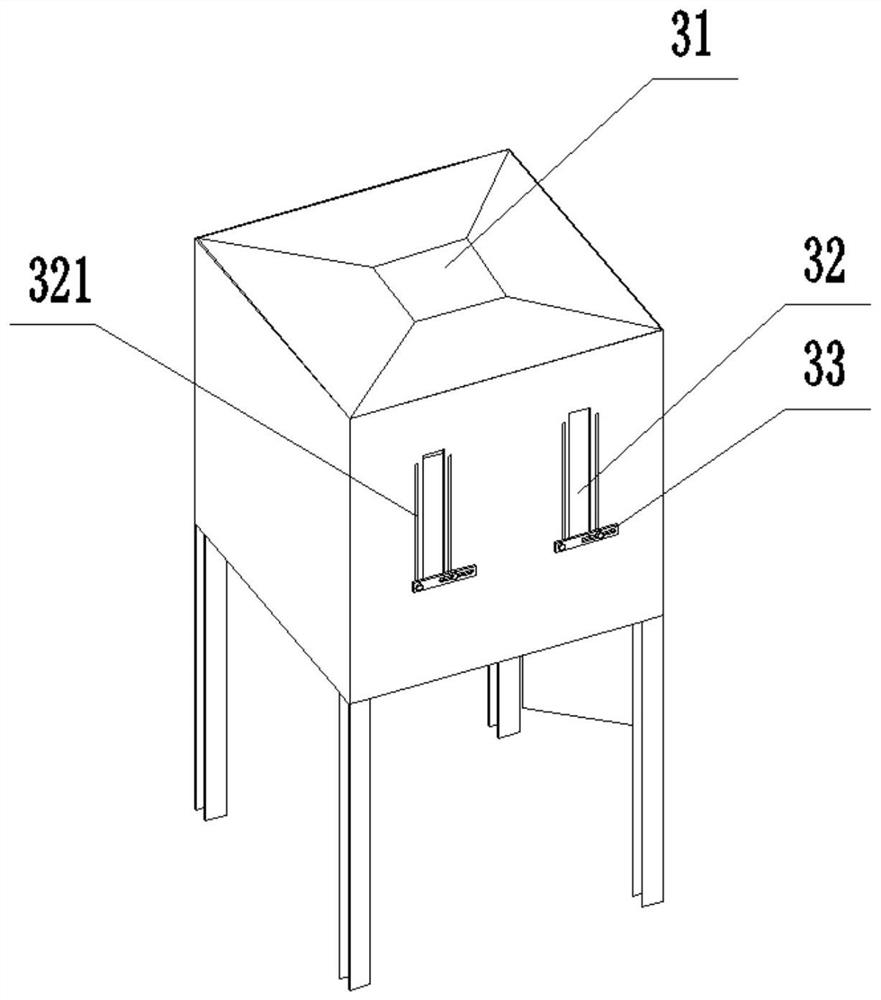

[0025] The distribution bin 3 includes a feeding funnel 31, two vertical strip-shaped transparent sealing windows 32 and a coarse quantitative mark 33; wherein, the feeding funnel 31 is located below the tee device 12; each tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com