Device for engineering pile detection static load test

A technology of static load test and engineering pile, which is applied in the direction of foundation structure engineering, foundation structure test, construction, etc., can solve the problems of affecting detection efficiency, long counterweight process time, hidden safety hazards, etc., to increase work efficiency and reduce quantity , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

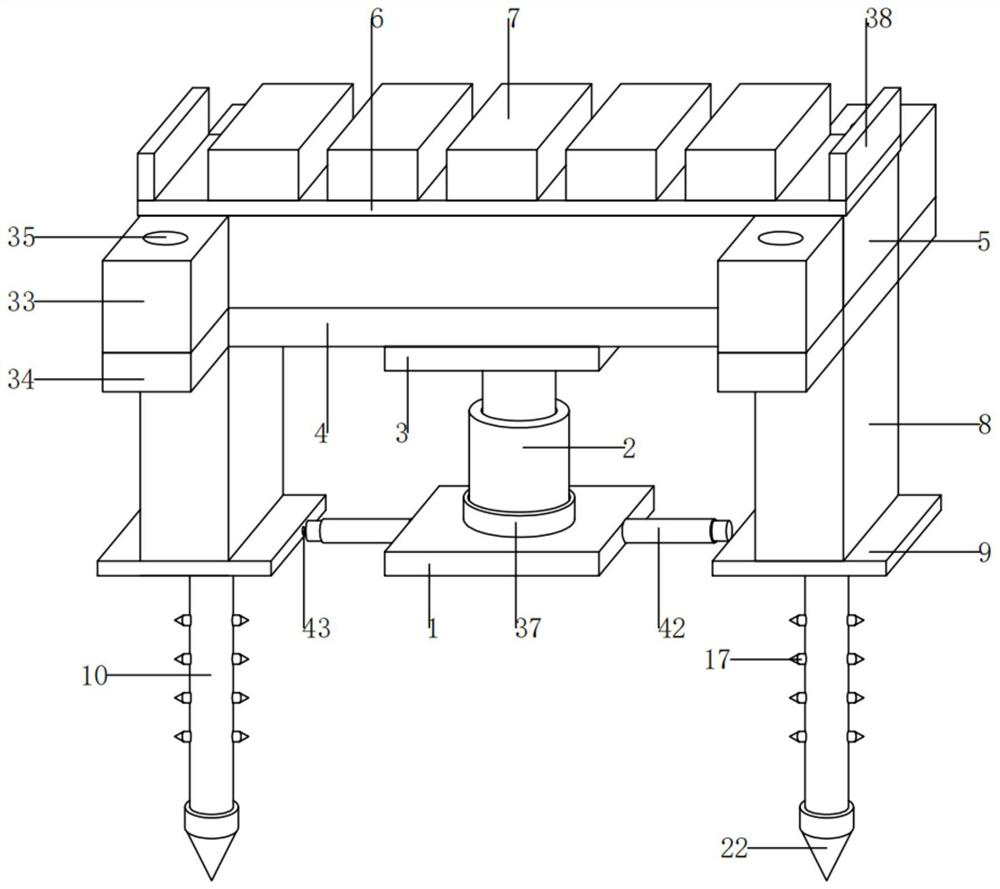

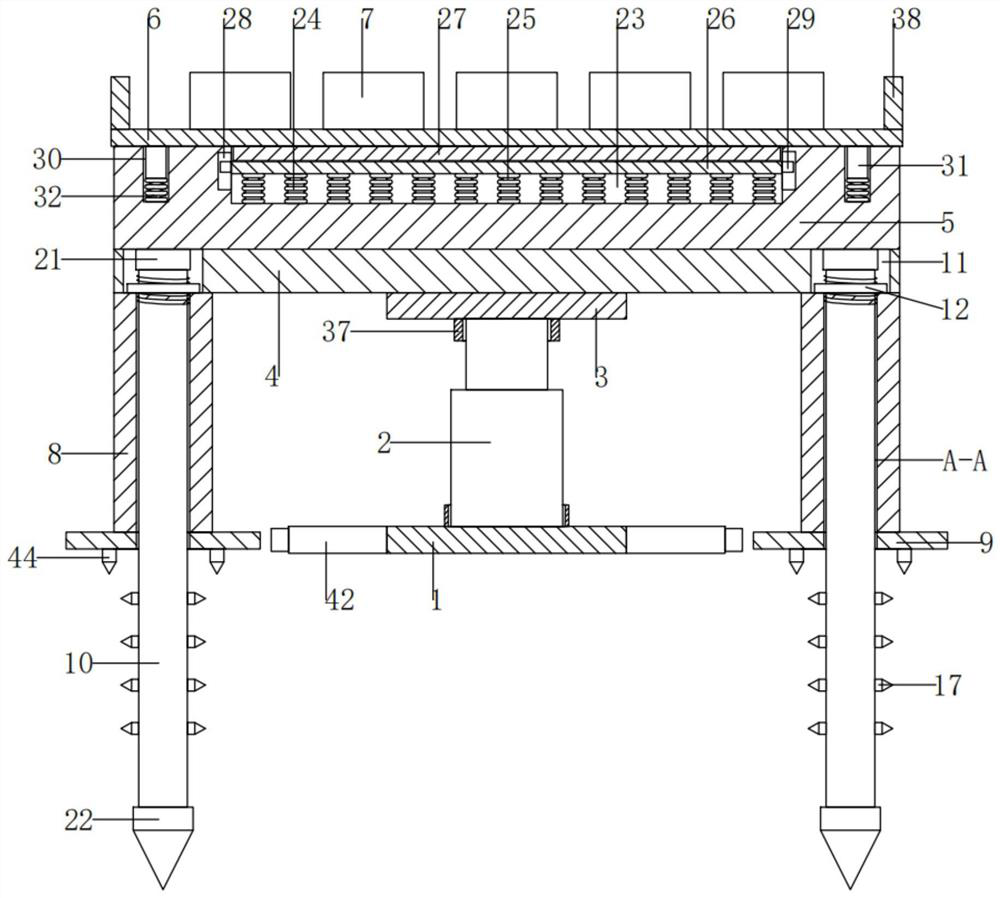

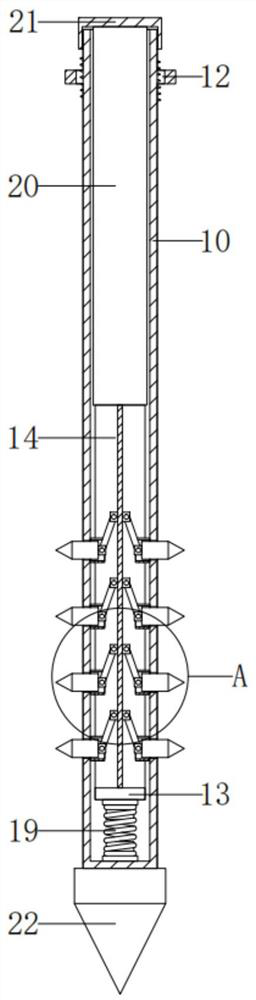

[0030] see Figure 1-8 , the present invention provides the following technical solutions:

[0031]A device for static load testing of engineering piles, comprising a lower bearing plate 1, the upper side of the lower bearing plate 1 is sequentially provided with a jack 2, an upper bearing plate 3, a connecting plate 4, and a stabilizing plate 5 , Place the plate 6 and a plurality of counterweights 7, the lower bearing plate 1 is in contact with the jack 2, and the lower end of the connecting plate 4 is provided with two piers 8, and the two piers 8 are respectively located on the left and right sides of the jack 2, The lower ends of the two piers 8 are all provided with a stable bottom plate 9, the lower ends of the two stable bottom plates 9 are all provided with insertion rods 10, the upper end of the connecting plate 4 is dug with two first installation grooves 11, and the upper ends of the two insertion rods 10 are From the bottom to the top, two stable bottom plates 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com