Acid gas self-purification centrifugal fan for coal mine work

A centrifugal fan, acid gas technology, applied in the ventilation of mines/tunnels, components of pumping devices for elastic fluids, liquid fuel engines, etc., can solve problems that are difficult to deal with, and achieve extended service life and enhanced Protects and enhances the effect of absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

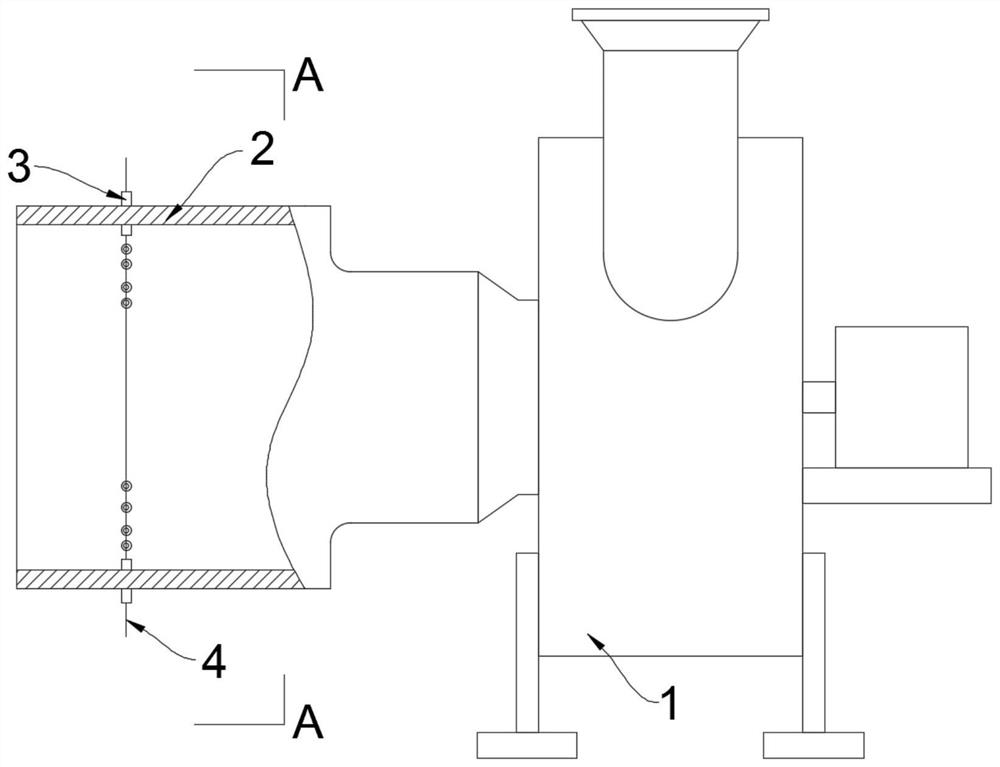

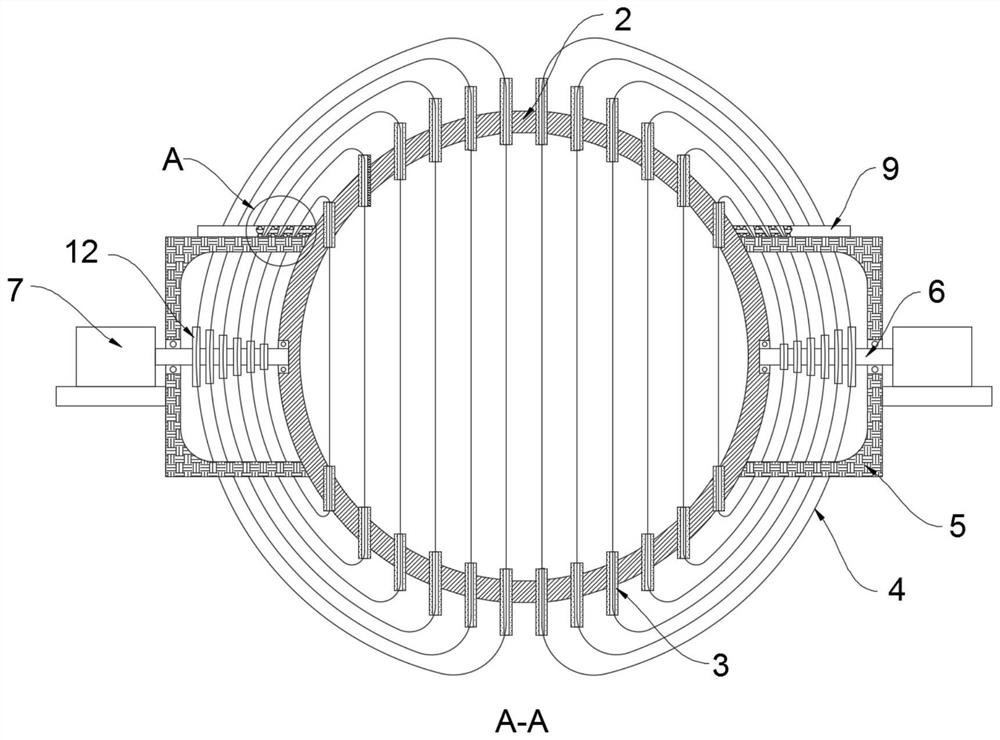

[0025] like Figure 1-3 As shown, an acid gas self-purifying centrifugal fan for mine work includes a main body 1 of the fan, and an air inlet pipe 2 is fixedly connected to the air inlet of the main body 1 of the fan, and the side wall of the air inlet pipe 2 is embedded with a A plurality of auxiliary cylinders 3, the two auxiliary cylinders 3 on the same vertical line are provided with a ring made of the same cotton thread 4, and the circumference of the ring made of cotton thread 4 increases sequentially from the outer ring to the inner ring. Both left and right sides of the pipe 2 are provided with drive boxes 5, and the drive boxes 5 are fixedly connected to the outer wall of the air inlet pipe 2.

[0026] In this embodiment, the multiple cotton threads 4 on the same side all pass through the side wall of the drive box 5 and are driven by the drive mechanism in the drive box 5. The drive mechanism includes a rotating shaft 6, and one end of the rotating shaft 6 is rotata...

Embodiment 2

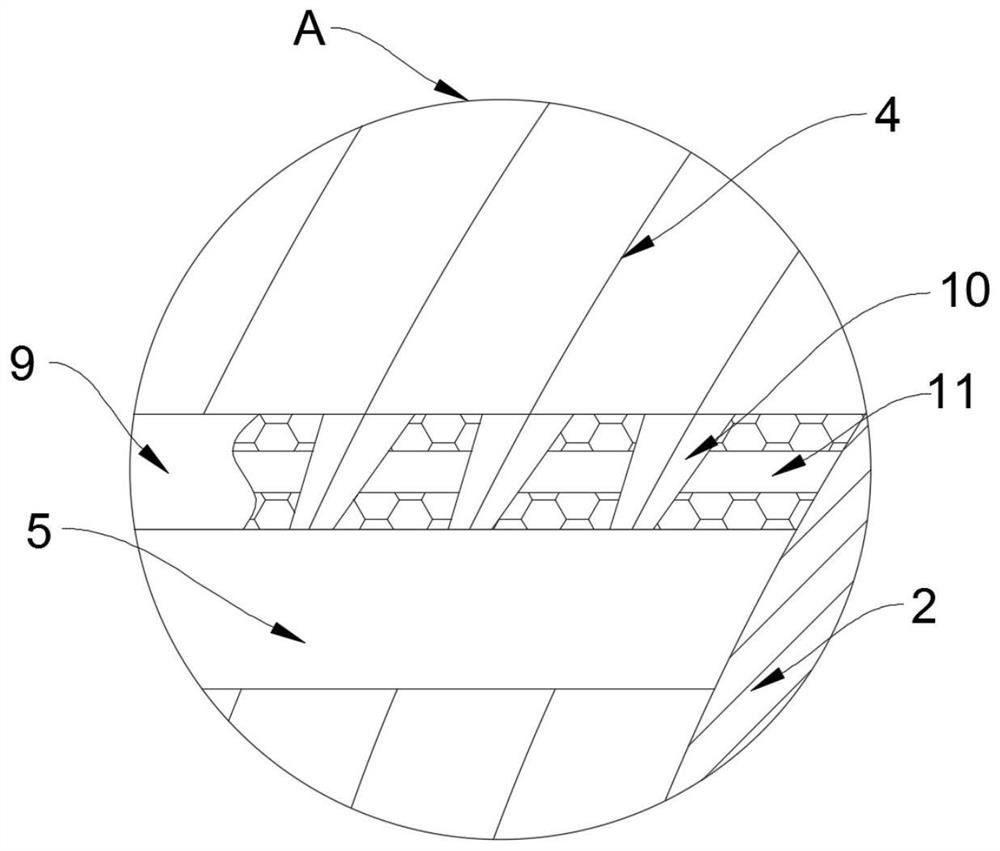

[0032] like Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that the air inlet pipe 2 includes two independent fixed pipes 21 and a rotating ring 22, and the rotating ring 22 is sealed and rotated with the outer walls of the two fixed pipes 21. Connection, specifically, the inner wall of the rotating ring 22 is fixedly connected with the connecting ring 14, the fixed pipe 21 is provided with an annular groove 15 matching the connecting ring 14, the connecting ring 14 and the annular groove 15 are connected in a sealed and rotating manner, and the auxiliary cylinder 3 1. The cotton thread 4 and the driving box 5 are both arranged on the outer wall of the rotating ring 22. It should be noted that the rotating ring 22 is provided with a plurality of air inlet holes 13 arranged obliquely.

[0033] In this embodiment, the setting of the rotating ring 22 is that the rotating ring 22 is rotatably sleeved on the outer wall of the fixed pipe 21. When a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com