Distributor and gas stove containing it

A technology for distributing firearms and air passages, which is applied in the direction of burners, combustion types, heating fuels, etc., can solve the problems of low heating efficiency of a single row of fire holes, insufficient combustion of multiple rows of fire holes, etc., to reduce the generation of carbon monoxide, Effect of reducing carbon monoxide generation and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

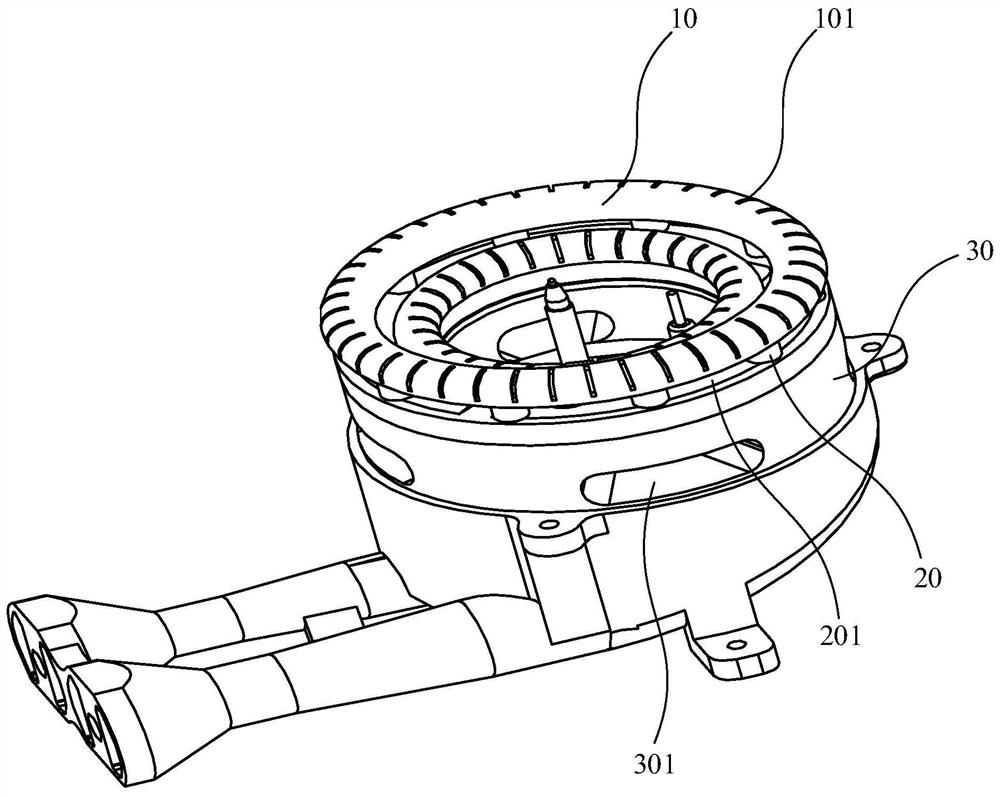

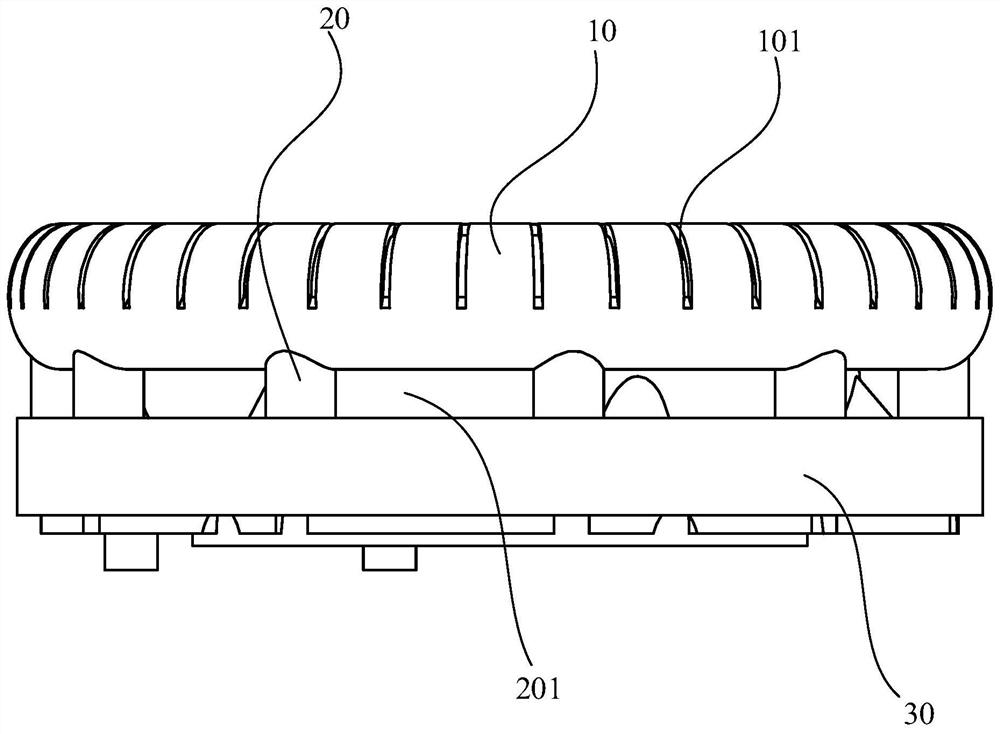

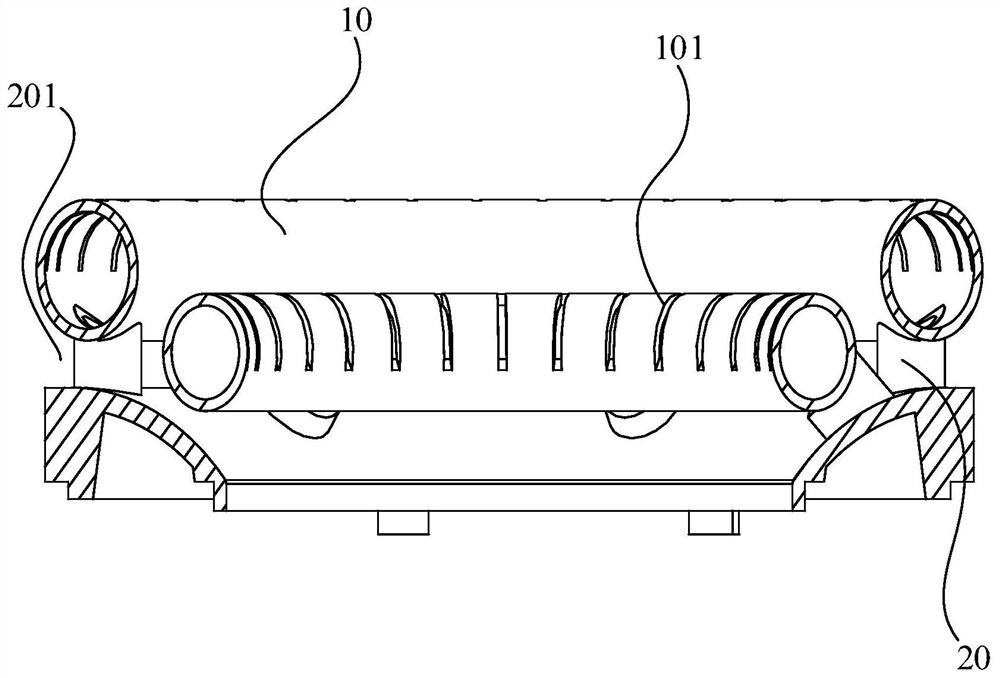

[0040] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a fire distributor, which includes a gas mixing chamber 30 and at least one gas mixing channel 10, the gas mixing channel 10 is connected above the gas mixing chamber 30, and the gas mixing channel 10 is hollow inside and connected to the gas mixing channel 10. The gas mixing chamber 30 is connected, and there is a gap between the gas mixing channel 10 and the gas mixing chamber 30 . The gas mixing channel 10 is provided with a plurality of fire holes 101 , and the fire holes 101 communicate the gas mixing channel 10 with the outside. The gas mixing channel 10 communicates with the gas mixing chamber 30 , so that the gas in the gas mixing chamber 30 is inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com