Waste heat two-stage recovery type split steam generator

A technology for steam generation device and waste heat recovery, which is applied in steam generation, steam boilers, removal of solid residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

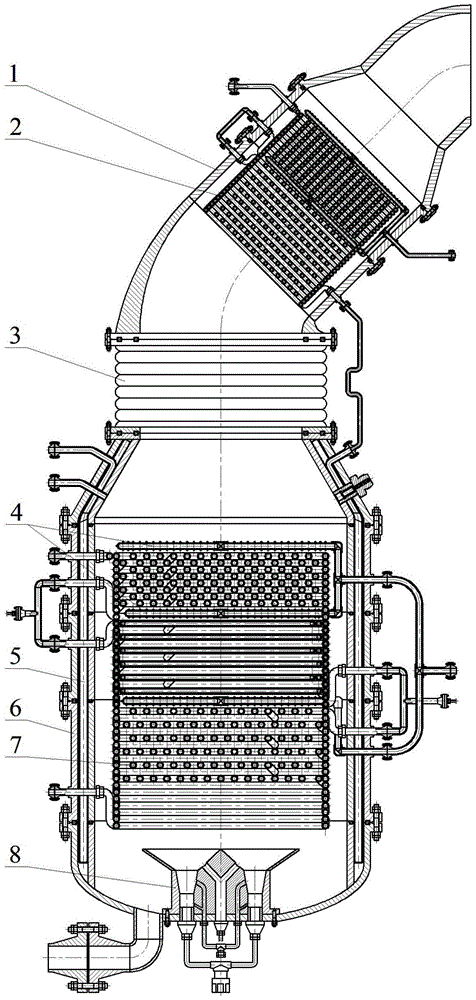

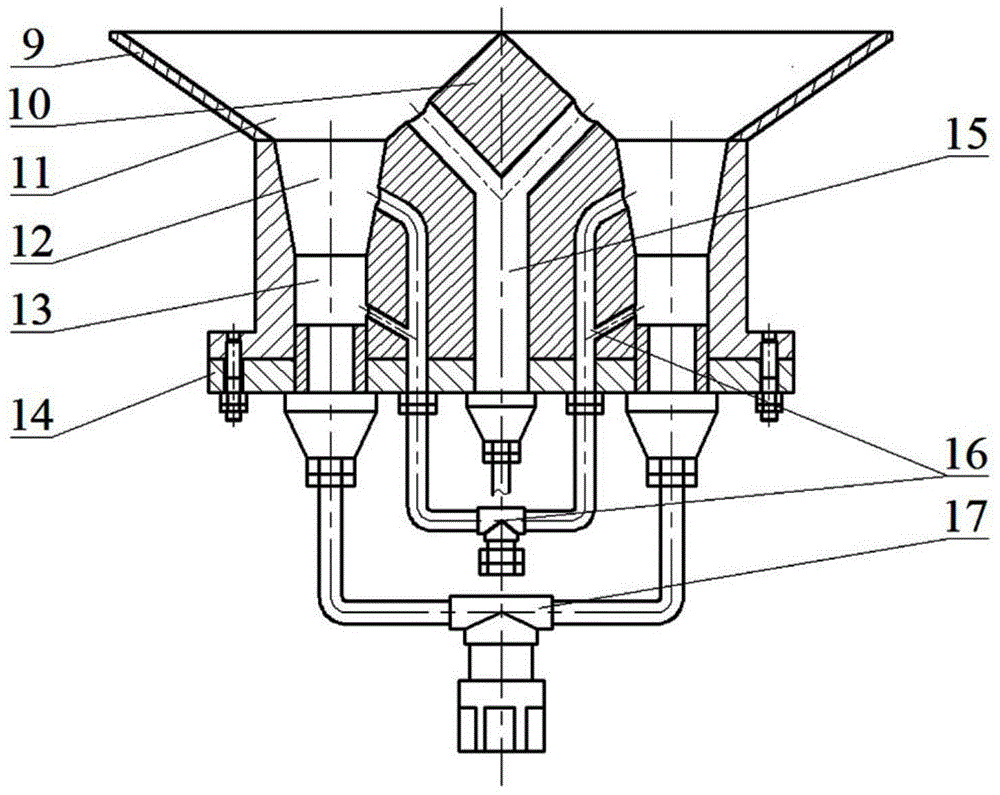

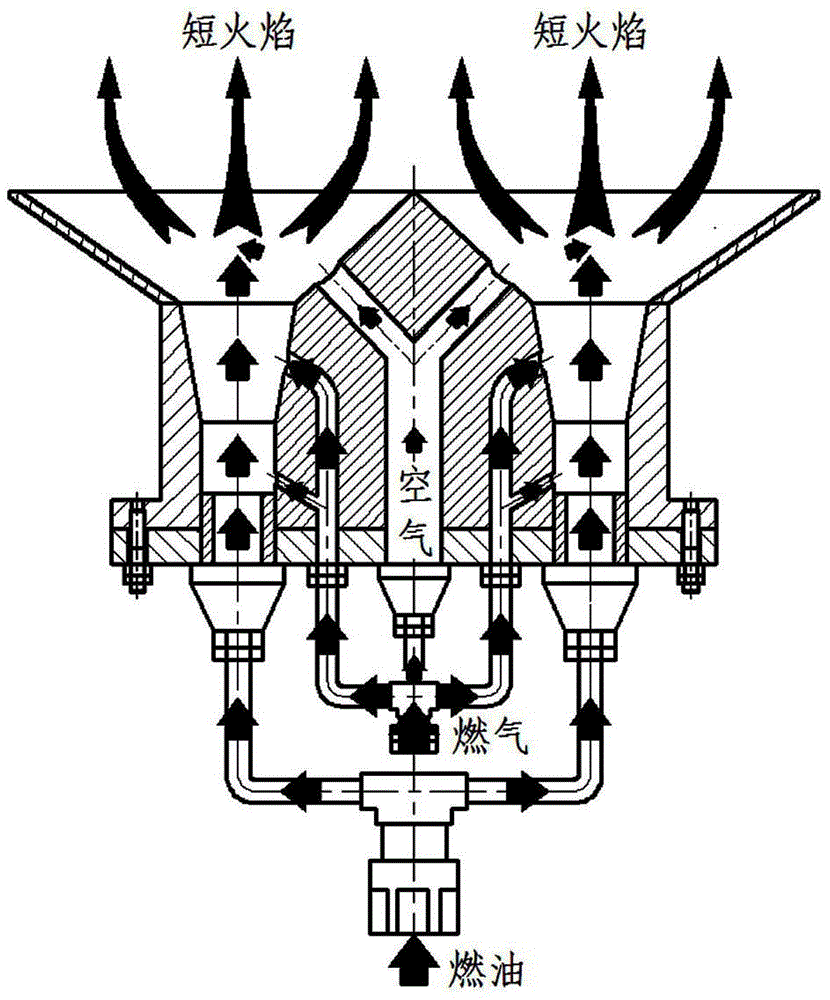

[0041]exist figure 1 Among them, the waste heat two-stage recovery type split steam generator consists of waste heat recovery device 1, secondary heat medium device 2, expansion joint 3, shower 4, primary cooler 5, combustion body 6, steam generating folded pipe 7, Composed of oil and gas dual burner 8 and steam generation control system. When assembling, first fix the oil-gas dual burner 8 to the middle part of the outer seal body of the combustion body 6 through the double combustion disc; The upper lower spray branch pipe, the middle cylinder and the middle folding pipe, the middle lower spray branch pipe, the upper cylinder and the upper folding pipe, and the upper lower spray branch pipe of the device 4; then the cooling pipe of the primary cooler 5 is arranged on the combustion body 6 and insert into the inner and outer cylinders; then connect the expansion joint 3 and the waste heat recovery device 1 in sequence, and arrange the thermal oil pipe of the secondary heat m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com